Editors’ Picks

Found in Robotics News & Content, with a score of 9.72

…attendees of our webcasts, there was strong interest in robots that worked well with people, including cobot arms in welding, goods-to-person systems paired with automated storage and retrieval systems (ASRS), and collaborative mobile robots such as those from 6 River Systems or Locus Robotics. Emerging teleoperation tools and software to manage growing robot fleets also did well. Check out the slideshow at right (below on mobile) to see Robotics 24/7’s top 10 robotics trends for 2022! Let us know what you think on LinkedIn. Editor's note: Eugene Demaitre and Cesareo Contreras make up the editorial staff of Robotics 24/7.

Found in Robotics News & Content, with a score of 17.03

…Yaskawa. FANUC's robots serve in many industrial applications, including welding. Source: FANUC FANUC a global robotics leader With over 900,000 robots sold, FANUC claimed that it is the world’s largest manufacturer of industrial robots. The company has been active in factory automation since 1955. It is headquartered in Oshino, Japan, where FANUC produces its robots in highly automated factories at the base of Mount Fuji. FANUC America is based in Rochester Hills, Mich. FANUC produces more than 100 models of robots, most of which are distinctively yellow. They range from large and small articulated robots for handling and welding to…

Found in Robotics News & Content, with a score of 7.14

…which robots may be applied such as machining or welding Industrial maintenance or mechatronics certification “It is important for FIRST to recognize the high value of skills and experiences that students gain through robotics programs,” said Chris Rake, Chief Operating Officer at FIRST. “The RMF credential unlocks exciting career pathways, helping us inspire young people to become leaders in robotics and advanced manufacturing, and we're proud to join SME in developing this program.” The RMF credential is ideal for high school and college students, dislocated workers, under-employed individuals, veterans, at-risk youth, and others who are seeking new employment in high-demand…

Found in Robotics News & Content, with a score of 18.57

…SpA this week said it has built an automated welding system for Beijing Foton Daimler Automotive Co., a joint venture between Daimler Trucks AG and Chinese truck manufacturer Foton Motor. It is supporting Foton Daimler's first localized heavy-duty truck for the Chinese market, the Actros, which is based on the Mercedes-Benz global platform and uses Daimler’s truck technology. “We are honored to have been selected by Foton Daimler to work on this milestone which paves the way to localizing its first heavy-duty truck. Daimler is a global leader in the automotive industry, not only because of its large volume of…

Found in Robotics News & Content, with a score of 11.78

…needed. “Although we’re very familiar and experienced with ultrasonic welding applications, integrating ultrasonic welders to the end of the robots was actually new to us,” said Hornsby. “Instead of moving a part manually or having a very customized fixture to move it around underneath our sonic welder, we chose the Epson T-Series All-in-One SCARA robots to automate the process for efficient speed, efficient costs, and efficient results.” Epson T-Series All-in-One SCARA robots are space-saving robots that install in minutes due to the controller being built into the base of the robot arm. They use the same intuitive software and powerful…

Found in Robotics News & Content, with a score of 40.26

…too costly and have a high learning curve for welding operators. Han's Robot this week introduced a new arc-welding system that it claimed can improve the accuracy, efficiency, and stability of welding. A shortage of skilled labor and conventional robots usually fail to meet the specific needs of many scenarios. Shenzhen, China-based Han's Robot said its collaborative robot addresses these challenges with easy teaching, a high level of safety, and flexible deployment. Han's Robot develops, promotes, and applies intelligent robots in manufacturing, healthcare, logistics, education, and other industries. The company said it has attracted more than $100 million in funding…

Found in Robotics News & Content, with a score of 11.36

…have been used for loading and unloading, bin picking, welding, palletizing, quality inspection, and more. Dobot seizes on market challenges The company said it made the Nova Series in response to labor shortages and rising costs in the service and retail industries. It said its robots can “replace workers to help reduce operating expense and decrease human contacts [sic] during pandemics.” “To better capture this newfound demand, Dobot has developed the Nova Series of collaborative robots designed specifically for retail customers to handle tasks such as making coffee, cocktail, ice cream, noodles, fried chicken, and even physical therapy,” it said.…

Found in Robotics News & Content, with a score of 11.15

…arm to perform fast and precise pick-and-place, palletizing, and welding tasks, the company added. The new cobot is also suitable for automated optical inspections (AOI), semiconductor and product manufacturing, and food-service preparation, among other applications, Techman Robot said. It can work with autonomous mobile robots (AMRs), it added. “It is the only intelligent robotic arm series on the market provided with a comprehensive AI software suite,” claimed Techman. The TM AI Cobot includes TM AI+ Training Server, TM AI+ AOI Edge, TM Image Manager, and TM 3DVision, allowing companies to train and tailor their systems for their specific needs, said…

Found in Robotics News & Content, with a score of 7.45

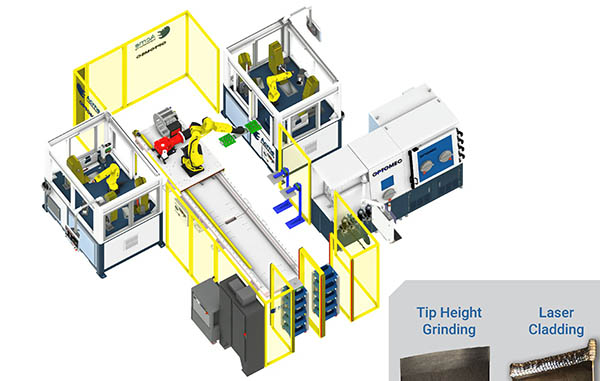

…when compared to traditional CNC machines and manual TIG welding.” The workcell uses commercially available technologies that have been certified by civil aviation authorities around the world, said the companies. The entry-level workcell consists of three stations that enable robotic blade tip grinding, 3D additive laser cladding, and robotic post-clad finishing. The cell also includes an automated pallet load/unload station, a pallet-flipping station, and a robotic material handling system. Each machine in the workcell is capable of automatically adjusting tool paths to accommodate blade-to-blade variations resulting from normal wear and distortion during service. Optomec said its CS-250 five-axis laser cladding…

Found in Robotics News & Content, with a score of 23.42

…dismissed as too heavy-duty a task for collaborative robots, welding is now the fastest growing application segment for Universal Robots A/S. The company said the channel grew more than 80% in the first nine months of 2022 in comparison with last year, with over 1,200 cobots expected to ship in the welding vertical this year. Since the first cobot-powered welder debuted in North America at FABTECH 2017, several OEM partners have standardized and innovated welding systems on the UR platform, said the company. At FABTECH 2022 next week in Atlanta, Universal Robots and its partners plan to display welding and…

Found in Robotics News & Content, with a score of 19.72

…600,000 welders in the U.S., according to the American Welding Society. Welding robots can help mitigate this shortage, but they need to accommodate customization. “All of our customers having a hard time hiring welders, whether they're in construction, agriculture, or automotive manufacturing,” said Dmitry Golitsyn, co-founder and chief technology officer of ABAGY. “Robots haven't been flexible or adaptive enough for non-serial production, and the time needed to reprogram them is not cost-effective,” he told Robotics 24/7. “We developed software for industrial robots to use computer vision, eliminating the need for programming.” “Teach pendants don't work for non-serial manufacturing; they're designed…

Found in Robotics News & Content, with a score of 30.85

Welding is one of the fastest-growing applications for robots. OTC DAIHEN Inc. this week announced that it has produced its 1,000th production robotic welding system. Partner Airgas Inc. sold the SERVO-ARC 720B turntable robot welder to East Manufacturing Corp. to augment its production of over-the-road trailers. “The completion of our 1,000th pre-engineered welding system represents 20 years of advancing robotic welding solutions by the OTC DAIHEN Inc. team,” stated Todd Griffieth, general manager for technical operations at OTC DAIHEN. OTC DAIHEN is the U.S. subsidiary of Osaka, Japan-based DAIHEN Corp. The company claimed that it is the world's No. 1…