Editors’ Picks

Found in Robotics News & Content, with a score of 12.73

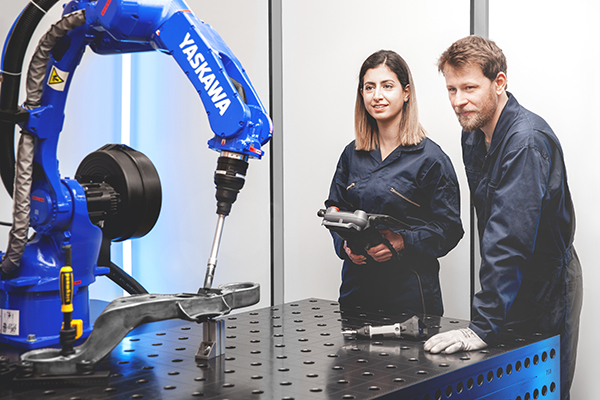

…company. For instance, a user can trace a new welding path on the workpiece with the TracePen input device in the hand and recorded by the software at the same time. The recorded path can then be edited, tested, and executed via the intuitive 3D user interface of the teaching app, Wandelbots said. The software automatically generates the manufacturer-specific robot code in accordance with current safety standards. To train the robots accordingly, companies need only the Wandelbots software and the TracePen, the company said. They can use them to implement numerous robot applications, such as welding, gluing, and material processing…

Found in Robotics News & Content, with a score of 12.70

…of perception-guided picking systems, vision-backed handling products, advanced arc welding systems and wearable robotics that help increase operator well-being during heavy and repetitive tasks. All of these offerings address the increasing shortage of skilled labor and the continued growth of automation, which is expected to exceed a growth of +10% CAGR 2022-2030, according to Comau company research. In addition to these technologies, Comau will unveil a new generation of compact robots that specifically address the diverse needs found within automotive and non-automotive applications. To help companies save time, energy and resources, improving the quality of the production processes, Comau’s fully-automated…

Found in Robotics News & Content, with a score of 12.63

…its new high-end SCARA line. Yaskawa displayed its cobot welding work table. FANUC’s booth included its new food-picking delta robot, along with the large FANUC 1000iA assembly robot. Other companies, such as Universal Robots, showcased technologies that are still a little ways off. The Odense, Denmark-based company displayed a concept cobot that had a smooth exterior that could work well in food handling and medical environments. The company said it is showcasing the concept now to get customer feedback. Check out the slide show on the right (bottom on mobile) for a deeper look at some of the most interesting…

Found in Robotics News & Content, with a score of 12.55

…large selection of standard utility modules and tool stands, enabling a wide array of unique configurations, ranging from ultrasonic welding to servo motor support and more.

Found in Robotics News & Content, with a score of 12.52

…tightening, machine tool loading and unloading, packaging and palletizing, welding, and cutting, the company said. Designed to work across industries The cobots are designed to be used across sectors such as automotive, 3C electronics, food and beverage, metal processing, paper converting, home appliances, power, and education, it added. CS stands for “Cobot Superior.” The Shanghai, China-based company said the CS Series features all the advantages of the previous EC Series and more. Elite said the new series embodies the flexibility and openness of a new generation of collaborative robots. The new series is based on the “platformization” concept, according to…

Found in Robotics News & Content, with a score of 12.47

…a wide range of applications, including material handling, paint, welding and laser cutting. ABB Robotics completed a rigorous application process, including a review by an IACET site visitor, to achieve its Accredited Provider accreditation. The organization successfully demonstrated adherence to the ANSI/IACET 1-2013 Standard addressing the design, development, administration, and evaluation of its programs. ABB Robotics has pledged its continued compliance with the Standard, and is now authorized to use the IACET name and Accredited Provider logo on promotional course material. In addition, ABB Robotics is now linked to the IACET web site and is recognized as offering the highest…

Found in Robotics News & Content, with a score of 12.45

…delved into uncharted territory to create a positive disruption in our industry in much the same way the modern welding processes supplanted rivets, revolutionizing the way ships are built,” said Charles Southall, Newport News’ vice president of engineering and design. “We’re proud to be leading the way.” The Navy hopes to cut lead times on important parts and find a way to produce spare parts at less cost. Source: NavyTimes

Found in Robotics White Papers & Archives, with a score of 12.44

…high-mix, low-volume applications like machine tending, piece picking and welding. This issue takes a deep dive into the cobot space, with features focused on how Collaborative Robots recently raised $30 million to launch its new Cobot Flywheel Program and develop its “practical cobot.” The program is focused on helping biotech, healthcare and logistics companies drive ambitious operational transformation with advanced robotics solutions. You’ll also learn how Omron Automation Americas is partnering with Jet Automation Inc., to jointly develop a new cobot palletizing system, and how Solo Brands is working with Locus Robotics to deploy 16 artificial intelligence-driven mobile robots at…

Found in Robotics News & Content, with a score of 12.34

…stacking them on pallets, feeding machines with raw materials, welding, and a wide range of other things. Automation leaves people with the opportunity to take on more demanding and meaningful tasks. The welder is still the person who knows their craft the best. As a robot supervisor, they can monitor the machine, ensure the quality is still at a high level, and perform the most complicated welding. However, no longer are they required to carry the torch alone for a full day. This is at least what work looks like in the ideal world. However, robotics as a field is…

Found in Robotics News & Content, with a score of 12.33

…using integrated force control’s “Phase search” function. A CRX-10iA welding cobot will allow attendees to teach weld joints using hand guidance or a tablet interface with drag-and-drop icons. The CRX welding cobot supports FANUC’s advanced features including iRVision, Torch Angle Control, Touch Sensing and Thru Arc Seam Tracking (TAST). The CRX will use Lincoln Electric’s Power Wave R450 robotic power source, and the new Lincoln Electric Smart Torch. Built for the industrial space, the CRX-10iA welding cobot is compatible with Lincoln Electric’s weld programs to help customers maximize productivity. A new CRX-25iA robot, offering a 25kg (55 lb.) payload and…

Found in Robotics News & Content, with a score of 12.29

…Hitech Bihca, submitting a joint redesign of a laser welding head. By 3D printing the laser welding head, multiple issues in the production environment were solved. This results in lower downtime, better welds, no damage to the laser or products and a higher productivity. Other Finalists In the student category this year is a medical application by Younes Chahid from BiomimeticAM with the Hip Implant Stem Design, from the University of Huddersfield (UK). With this redesign of the hip implant stem, issues with implant revision surgeries and bone resorption could be greatly improved. The new design of the hip implant…

Found in Robotics News & Content, with a score of 12.23

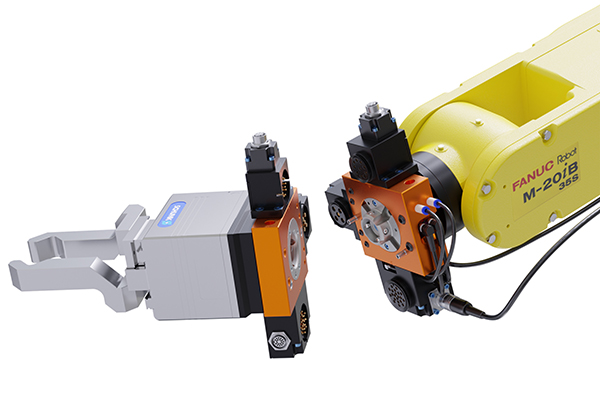

…forces, making this an ideal offering for friction stir welding, drilling and riveting applications. “We’re thrilled to introduce our new robot to the market,” said Eric Potter, general manager of FANUC America’s Robot Application Segment. “It’s design is perfect for rapid and robust performance in heavy part lifting, palletizing, and demanding material handling tasks. With its exceptional strength and versatility, the M-950iA is set to become a powerhouse for customers seeking adaptable solutions in challenging industrial environments.” Other features of the M-950iA/500 include: 6 controlled axes High-performance servomotor drive system offering positioning repeatability of ±0.08 mm User-friendly FANUC iPendant teaching…