ATI Industrial Automation Inc. today said it is releasing the QC-29 tool changer, a new standard option for smaller robots.

Founded in 1998, ATI Industrial Automation develops robotic accessories and robot arm tooling. The Apex, N.C.-based company said its end-of-arm tooling (EOAT) can enhance the productivity and flexibility of automation across a wide spectrum of industries. It provides automatic tool changing, force-torque sensing, material removal, and more capabilities.

In July, Novanta Inc., a Bedford, Mass.-based industrial and medical equipment manufacturer, said it planned to acquire ATI for $172 million.

ATI designs QC-29 for robust light robot tool changing

_-_Master_Plate_(R).jpg)

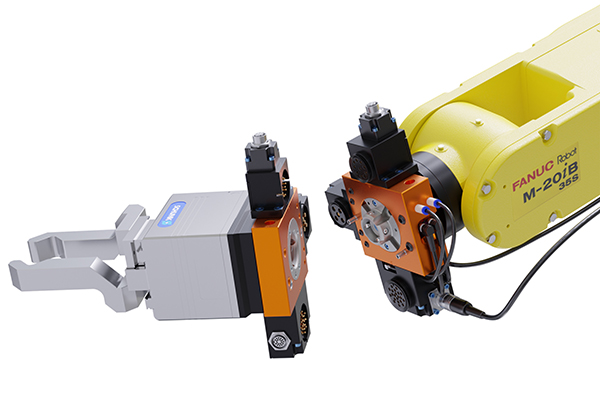

ATI Industrial Automation said its QC-29 Robotic Tool Changer brings the rugged technology of its heavy-duty tool changers to collaborative robots and lighter industrial robot arms, specifically those in the 25 to 35 kg (55.1 to 77.1 lb.) payload range.

The company added that the QC-29 is its first standard tool changer designed with a rectangular body that mounts directly to 40 mm (1.5 in.) and 50 mm (1.9 in.) robot wrists.

The QC-29 also includes in-body lock/unlock sensing and a new locking mechanism. Built-in air ports and three module mounting flats make connecting utilities easy, said ATI.

In addition, the Zero-Freeplay design ensures maximum repeatability for high-efficiency tool changing, it said.

ATI also said the QC-29 is compatible with its large selection of standard utility modules and tool stands, enabling a wide array of unique configurations, ranging from ultrasonic welding to servo motor support and more.

Article topics

Email Sign Up