Editors’ Picks

Found in Robotics News & Content, with a score of 1.22

…that travels autonomously into the warehouse storage, finds the inventory locations, individually identifies objects, and picks the objects.” IAM’s units have been deployed at companies including Rochester Drug Cooperative. A recent twist on IAM Robotics’ technology is the Swift Picking Module, which functions like a flexible automated storage and retrieval system (AS/RS), but rather than being an enclosed storage infrastructure with an enclosed crane or other movement mechanism, it uses IAM’s mobile manipulation robots and an open shelf environment. The major advantage of a mobile manipulation robot, says Reed, is that it automates both movement and picking/transfer of goods. “We…

Found in Robotics News & Content, with a score of 1.22

…which can be used to map the location of inventory to form a database of information over time. Slamcore’s spatial-temporal digital twin doesn’t require a database with petabytes of data because everything is logged in a simple format. Currently, that data includes an object name, a coordinate, and a timestamp. Because the data is numerical at its core, it’s easily searchable in real time. Nicholson said generative AI is the perfect tool to extract meaningful information from the digital twin. Because all the information is interconnected through time and location, operators can use generative AI to ask questions about things…

Found in Robotics News & Content, with a score of 1.19

…go away.” Also, Schell predicted a massive impact of inventory reductions across the entire value chain. “Today with digital manufacturing, you will spend money as you need a part,” he said. “So for a CEO going from a centralized way of looking at manufacturing to distributed way of looking at manufacturing is going to have massive impacts.” The value chain of today’s manufacturing process starts with design, according to Schell. Next is the role that data plays. “Data informs how we optimize the build process. But it also informs how you integrate a printer into the workflow of the factory.…

Found in Robotics News & Content, with a score of 1.13

…maintenance supply chain by right-sizing maintenance parts and optimizing inventory to actual conditions at a location.” Among the other benefits being realized by condition-based maintenance is a 65% reduction in the mean time to repair, a significant improvement given that the company manages 5,000 connected chillers in 37 countries. It is also contributing to revenue, with a service contract renewal rate of more than 90% for those companies on CEP. “That’s the best metric of success we have,” he says. The original program is now undergoing next generation improvements with the help of artificial intelligence and machine learning that learns…

Found in Robotics News & Content, with a score of 1.11

…robots are dedicated to one customer. Receiving: All incoming inventory is received in floor-loaded shipping containers. The containers are manually unloaded to pallets and scanned into NFI’s warehouse management system (WMS). Putaway by reach trucks is system directed. Pick module storage: Replenishment of the picking area is also system directed: The WMS sends a task to an associate, who retrieves the required pallets and cartons from storage and then scans them into a picking location. The picking area includes full pallet pick locations as well as flow rack for fast movers. The determining factors are the velocity and the size…

Found in Robotics News & Content, with a score of 1.10

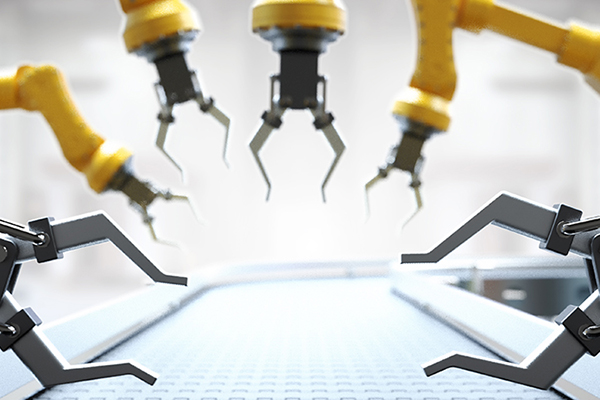

…can help connect robots with business systems, such as inventory databases, so a robot knows where an item is located. Simulation of cobots, or robots working with humans, promises to reduce injuries and make jobs easier, enabling more efficient delivery of all kinds of products. And with packages arriving incredibly fast in homes everywhere, what’s not to like? You can learn more on NVIDIA's site about Isaac Sim, Jetson Orin, Omniverse Enterprise, and Metropolis, as well as from this Deep Learning Institute course: “Introduction to Robotic Simulations in Isaac Sim.” About the author Gerard Andrews is a senior product marketing…

Found in Robotics News & Content, with a score of 1.04

…of what’s on the pallet is uploaded into the inventory system. Incoming pallets have a “license plate” RFID tag that itemizes the number of bins on the pallet and the product in each bin. The bins themselves have an identifying bar code. When a lift truck unloads a HARTING pallet, an onboard RFID reader automatically scans the tag. The system then tells the operator where to stage the pallet in the receiving area. Pallets from external suppliers are manually scanned and then directed to a staging area. Pallet storage Some pallets will be stored as is in a pallet-handling ASRS…

Found in Robotics News & Content, with a score of 0.64

…gain; the $36 billion pipeline sector rose 5.8%; and inventory storage and financial costs rose a total of 4.6%, with administration costs rising a similar 4.9%. Several shippers and carriers on the panel at the State of Logistics press briefing were queried about how they were handling the new pricing environment. Sylvia Fouhy, vice president of customer experience at Johnson & Johnson, says that capacity constraints are causing her company “to look at transportation as an investment rather than a cost of operations.” Another member of the shipper panel, Cheryl Capps, vice president of global supply chain at Corning International,…