Editors’ Picks

Found in Robotics News & Content, with a score of 1.24

…relationships such as the aisles and the locations of inventory in shelves and racks. What it doesn’t know is distance, traffic congestion and the current status of people on the floor. “We can look at traffic and congestion for more efficient path planning when we get a wave of orders,” Nasser says. “This is a level of real-time data that isn’t visible to the WMS.” Nasser thinks of this data sharing as “closing the loop” between the robotic system and the WMS. In another example, Fetch robots are scanning RFID tags throughout the warehouse to create a visual map of…

Found in Robotics News & Content, with a score of 10.09

…needed. In turn, every shelf is now a robot that has intelligence, leading to faster pick speeds and enhanced inventory accuracy, as employees no longer need to pick up or move shelves. Consequently, human error is reduced entirely. “The Auto Shelf is changing how inventory is handled,” said Eric Rongley, CEO and founder of Prime Robotics. “It’s completely turned the warehouse robotics paradigm on its head.” Modex 2020 is scheduled to be held March 9-12 at Georgia’s World Congress Center in Atlanta. The tradeshow will showcase the latest manufacturing, distribution and supply chain solutions in the materials handling and logistics…

Found in Robotics News & Content, with a score of 2.16

…some kind of mobile or handheld system, either for inventory management or manual data entry. According to surveys by Renovotec, around 70% of the industry currently relies on Windows-based mobile operating systems for their devices - despite the fact that support for these systems is due to end in January 2020. With many of these devices now outdated and open to security risks, now may be the time to switch to an Android based system, such as those offered by Honeywell. These devices can be just as durable, and will benefit from an increase in speed and functionality. The Android…

Found in Robotics News & Content, with a score of 3.47

…now,” stated Schechter. “Many European firms already manage their inventory using tote systems that are ready to automate with RightPick, our piece-picking solution. We are very excited to officially expand our operations to better support our current customers and partners there, and I welcome any additional prospects to reach out to me directly.” Logistics robot integration and supply chain industry expert Manfred Preiss with more than 30 years experience added, “Robotic piece-picking will have a tremendous impact in warehouses across Europe and I’m thrilled to see RightHand Robotics, as a leader in this space, getting traction in Europe. Their impressive…

Found in Robotics News & Content, with a score of 3.25

…ushered into logistics and transportation practices, from tightening up inventory and fulfillment management to elevating the importance of final-mile delivery and returns processes—and everything in between. To respond, logistics professionals now need to leverage diverse systems and new ways of thinking in an effort to improve carrier partnerships and increase speed and efficiency. With that in mind, the editorial staff of Logistics Management (a sibling site to Robotics 24/7) has put together a collection of features to help readers push that pace of change inside their organizations. Contributing editor Roberto Michel offered shippers a high-level look at the role that…

Found in Robotics News & Content, with a score of 4.45

…Dell Technologies A multinational aerospace company needed to optimize inventory and address shortages. Furthermore, the company’s analytics sat on 600,000 speadsheets. In just 61 days, LeanDNA went from demo to first action on a new automated solution. That hope for inventory reduction hit 36% in just three months. Dell’s repair operation was the focus of their award-winning analytics solution. In 18 months, the project went from conception to pilot on the road to a 25% improvement in repair efficiency and a 50% reduction in no fault found events. Dell is now on the path to a 50% improvement in overall…

Found in Robotics News & Content, with a score of 3.08

…in production lines for barcode reading, quality control, and inventory management. “These solutions often have long replacement cycles and are less prone to disruption. Due to the increasing demands for automation, machine vision is finding its way into new applications,” said Lian Jye Su, Principal Analyst at ABI Research. “Robotics, for example, is a new growth area for machine vision: Collaborative robots rely on machine vision for guidance and object classification, while mobile robots rely on machine vision for SLAM and safety.” A different breed from conventional machine vision technology, deep learning-based machine vision is data-driven and utilizes a statistical…

Found in Robotics News & Content, with a score of 1.55

…the fulfillment center. The other is orders that include inventory not stocked in North Haven. At that point, “the number of factors will determine how an order like this gets fulfilled,” says Walker, adding that “the number one factor will be customer preference.” If a customer has chosen to receive items as they’re ready to ship, then Amazon may send multiple boxes to meet the promised delivery time. If a customer has chosen to receive items in one box, then the items will be merged at another fulfillment center, like the facility in nearby Windsor, and then go through the…

Found in Robotics News & Content, with a score of 3.18

…to optimize services using 3D printing and a digital inventory of original train parts, facilitating the in-house replacement and production of spare vehicle components. Dedicated to servicing the existing 16 and additional 13 planned trains for the next 30 years, Siemens Mobility Russia is working with more than 99% fleet availability record. “These availability figures would be physically impossible to achieve through external part sourcing and traditional manufacturing techniques alone, but Stratasys’ FDM 3D printers gives us the capability to cost-effectively produce the parts in-house, partially eliminating the need for warehousing or tools for a selected range of items,” says…

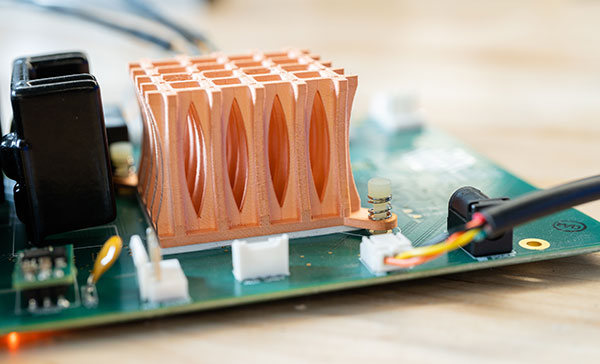

Found in Robotics News & Content, with a score of 5.78

…costs, as well as eliminating the need for costly inventory. Available today, Markforged provides an easy and fast way to produce geometrically complex copper with high electrical and thermal conductivity. “Copper powers our world. It’s everywhere. It builds our cars, enables phones, and keeps electrical equipment running,” says Greg Mark, Markforged CEO and founder. “Copper has traditionally been an expensive and challenging material to machine and incompatible for 3D printing in a pure form with other techniques. Now, we’ve made it easier and cheaper to produce. Markforged 3D printed Copper will be a game-changer for the automotive and electronics industries,…

Found in Robotics News & Content, with a score of 6.31

…By combining the right hardware, software, processes and people, Best Buy has achieved a better supply chain operation, from inventory management and increased order accuracy, to improved lead times for superior customer service and an overall reduction in costs.

Found in Robotics News & Content, with a score of 3.07

…works” the uninitiated think, assuming that an integrator or inventory management supplier will. “Maybe I’m living under a rock, but I don’t see an appropriate amount of attention paid to the nitty-gritty parts of putting a system together,” Hill says. “A lot of folks with technology like augmented reality, machine learning and robotics come to us to explain what they’re doing. When they start at the high level it’s very intriguing. Then when it gets down to what is available today, and how to start down the path to total integration and total visibility of inventory, the reality is that’s…