Editors’ Picks

Found in Robotics News & Content, with a score of 2.79

…for a product platform that can pick items from inventory storage bins, induct items to sorters, or place items into outbound orders in this vision of the future. So, what’s holding this prediction back? After looking at adoption curves for technologies across many industries over the years, we find that it takes some time. When the people who need a new product meet it for the first time, a whole new set of needs and opportunities arise. A piece-picking machine may be able to pick most of the products in a warehouse at a reasonable rate without damaging or dropping…

Found in Robotics News & Content, with a score of 2.79

…palletizing cell. Source: NorthShore Care Supply Robots grow with inventory Fast forward to July 2021, when I toured the Green Oaks facility once again. The AMRs were still traveling through the aisles, associates were busy picking to the robots and moving product through the packing stations, and lift truck operators were moving pallets to replenish pick locations. I saw two big differences: Significantly more inventory was in the warehouse than in July 2020, and at the receiving dock, two associates were unloading cartons onto a powered conveyor from inside a shipping container. Those cartons were then directed to a robotic…

Found in Robotics News & Content, with a score of 2.78

…consumer goods (FMCG), among other industries. The goods-to-person Butler, an AI-enabled autonomous robot, optimizes the supply chain process from inventory storage and replenishment to order picking. The Butler PickPal combines AI and Machine Vision to revolutionize automated fulfillment, working in tandem with the Butler to accelerate multi-fold the pick process in fulfillment centers.

Found in Robotics News & Content, with a score of 2.78

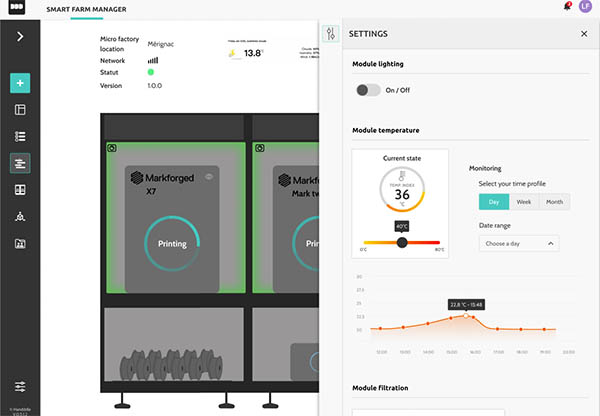

…service lives or as part of a digital kanban inventory system. “Markforged is known for its 3D printing reliability and repeatability, enabling production of industrial parts at scale,” said Julie van der Hoop, product manager at Markforged. “However, some industries or critical parts require clear reporting on constant production parameters, event history, and production data for certification before they can be put to end use.” “This integration is intended to make it seamless to import, slice, print, and monitor, with all of your production data in one place,” she added. Integration to improve AM production consistency Handddle and Markforged said…

Found in Robotics News & Content, with a score of 2.77

…CEO of Optoro. “Together, we can help retailers move inventory faster and more efficiently through the supply chain, cut costs, minimize their environmental impact, and improve the customer experience.” Washington, D.C.-based Optoro said it offers data science and real-time decision-making automation to improve the returns process. The company said that its customer returns portal is easy to use and provides warehouse processing and resale software. Optoro cited leading retailers and brands – including American Eagle, Best Buy, Staples, and IKEA – that trust its technology “to make returns a strategic advantage for their business and enable sustainability initiatives across their…

Found in Robotics News & Content, with a score of 2.77

…added. “Gravity provides reduction insights at the intersection of inventory and cost of different systems,” said ElHattab. “You can not only get the reduction potential, but also the cost savings per year from reduced energy consumption.” Selectivity and urgency Gravity Climate has done most of its business in the U.S., and it has worked with SHV Energy, the largest off-grid utility provider in the Netherlands and 25 countries, said ElHattab. “We're being selective about global expansion,” he said. “We're also looking at how to make carbon-reductive pitches in the construction space that are cost-effective.” “We're also looking at freight moving,…

Found in Robotics News & Content, with a score of 2.76

…is true whether the activity is order fulfillment or inventory replenishment in the DC or the micro-fulfillment center. Filling those orders faster than ever has an end game—compete with Amazon. “It is now in consumer’s minds that two-hour order delivery is not out of the ordinary, thanks to Amazon,” says Marc Wulfraat, founder and president of MWPVL International. “If you try to fight their strategy, you will lose,” he warns. Micro-fulfillment, filling e-orders in the back of existing retail space, is expected to be a $1 billion segment of the materials handling industry less than 24 months from now. Once…

Found in Robotics News & Content, with a score of 2.75

…attracted much attention by the unique ability of cargo inventory, storage management, and safety warning,” Han said. Stacking from Atlanta to Seoul At the MODEX 2022 materials handling trade show last week, VisionNav Robotics introduced its industrial automated vehicles to the North American market. The company said it displayed a representative automated forklift to show how intelligent automation can help the logistics industry. “Many companies talked to us about the shortage of forklift operators and the possibility of introducing automated forklift operations affected by the epidemic,” said Robert Tang, head of U.S. sales at VisionNav. “Our products have plenty of…

Found in Robotics News & Content, with a score of 2.73

…goods-to-person P-800 picking robot, which is suitable for connecting inventory with warehouse employees. It will also show the award-winning RoboShuttle, which enables high-density storage, and the S-20C, a sorting robot capable of connecting the disparate elements of a production or distribution line. Paack makes major AMR deployment in Madrid Barcelona, Spain-based Paack delivers several million orders per month from 150 international customers. They include 17 of the 20 largest e-commerce retailers in Spain, including Amazon, Apple, Inditex, AliExpress, Nike, and Nespresso. The company offers coverage in more than 100 European cities. In January, Paack secured $225 million in Series D…

Found in Robotics News & Content, with a score of 2.73

…and acts like a person to pick cartons; and the machine vision behind PINC’s drone technology used to take inventory in warehouses. “We don’t yet know the limits of AI,” Babu said, “but every day, we’re discovering new use cases.”

Found in Robotics News & Content, with a score of 2.72

…metrics such as product throughput, machine downtime, capacity, and inventory levels. Arena, owned by Rockwell Automation, topped the Followers category due to strong performance in data modelling and analytics. Arena’s complex variability modeling capabilities and its strong installed base within the market contributed to a strong score in implementation. “Ultimately the companies that scored best in the ranking can go beyond high-level factory layout simulation by also accurately modeling and commissioning industrial equipment on the factory floor and incorporating product design into the simulation environment. This means the way machines behave and how they are used to manufacture actual products…

Found in Robotics News & Content, with a score of 2.72

…such as a warehouse with a lot of different inventory in different places. One of the most common use cases would be to have AMRS that know where every part of a floor plan is. They could then navigate well around obstacles, avoiding people's workspaces and other off-limits areas. This is related to the next point. 5. AMRs offer agility Another popular reason to adopt mobile robots is that they can adapt to changing product flows and environments, unlike fixed conveyors. When a factory or warehouse hires a human worker, each one must ascend a learning curve to eventually know…