Editors’ Picks

Found in Robotics News & Content, with a score of 2.89

…AMRs, including object identification and recording of movement and inventory. Indoor operations can also improve efficiency and productivity because the robots are now able to consistently avoid obstacles and humans through recognition and real-time path adjustments and alerts, said RTI. With this optimized functionality, equipment and mobile robot manufacturers are freed from solving the complex challenges of autonomous mobility and can focus more heavily on product and technology innovation, the company said. “634AI is achieving groundbreaking feats by developing a solution that not only reduces vendor costs, but [also] allows users a higher degree of productivity and innovation in a…

Found in Robotics News & Content, with a score of 3.16

…addition, Geek+ said its systems enable real-time visualization of inventory, as well as the unification of material information and physical logistics scenarios. It said this makes it easier to follow, control, and adjust the manufacturing process. With intelligent algorithms and “heat map” software, Siemens can adjust the logistics operations daily according to the production plan, for maximum efficiency and flexibility, it added. Geek+ noted that Siemens Switchgear Shanghai expects to use its hardware and software to improve customer service and provide a safer environment for warehouse employees. Through the integration of big data and the ability to fine-tune the system,…

Found in Robotics News & Content, with a score of 2.21

…its technologies elevate the shopping experience, track and manage inventory, as well as improve supply chain efficiency and patient care. The company uses the same rugged hardware for its MV smart cameras and fixed industrial scanners. Both use Zebra Aurora, a unified software platform that the company said is easy to set up, deploy, and run. Zebra claimed that its machine vision can help reduce defects as well as validate assembly and tracking information to improve productivity and quality. “Zebra Aurora is focused on entry-level and midlevel machine vision challenges, while Adaptive Vision is focused on high-end customers,” Montanari told…

Found in Robotics News & Content, with a score of 4.18

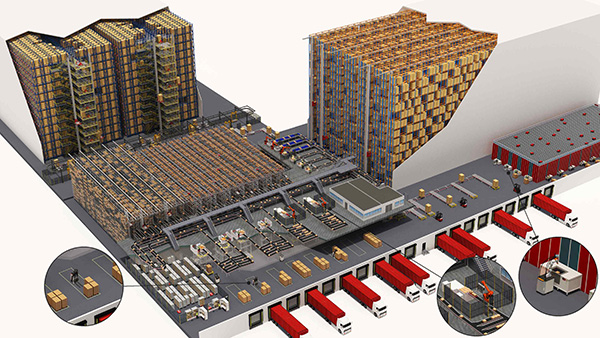

…and automated guided carts (AGCs). The third task is inventory management, which even includes the use of aerial drones. Let’s take a closer a look at the eight types of robots that are commonly used in warehouses today. Which types of robots are best to deploy always depends on the unique circumstances of a warehouse’s operations, facility, and overall goals. This is why we always recommend seeking advice from a specialized supplier or integrator. About the author Michelle Schlechtriem is the content manager at Meili Robots. She writes about marketing, technology, and sustainability. Meili Robots provides a universal fleet management…

Found in Robotics News & Content, with a score of 2.13

…but also in reducing the risk of damage to inventory, trucks, or to facility assets.” The rise of automated lift trucks Lift truck providers agree that automated vehicles are bound to grow in popularity given the continued challenges. And while warehouse efficiency efforts often focus on automated order-picking systems, goods also need to be handled, staged or stored at the pallet level, which presents opportunities for robotics. “I firmly believe this pandemic will accelerate the adoption of automated lift trucks, as well as many other forms of materials handling automation,” said Brett Wood, president and CEO of Toyota Material Handling…

Found in Robotics News & Content, with a score of 1.46

…do it all, they can get best-in-class systems for inventory, floor scrubbing, or materials handling,” said InOrbit's Pestoni. “You get very quickly from one vendor and one task to multiple tasks and robots.” “We already have multiple robots, including tuggers, pallet trucks, and counterbalanced forklifts,” said Vecna's Theobald. “It doesn't make sense for each robot manufacturer to integrate or for each WMS or WES [warehouse execution system] vendor to be expert in every robot,” Pestoni said. “We provide a thin orchestration layer in the cloud, and the system knows what needs to be done. It uses an API [application programming…

Found in Robotics News & Content, with a score of 1.55

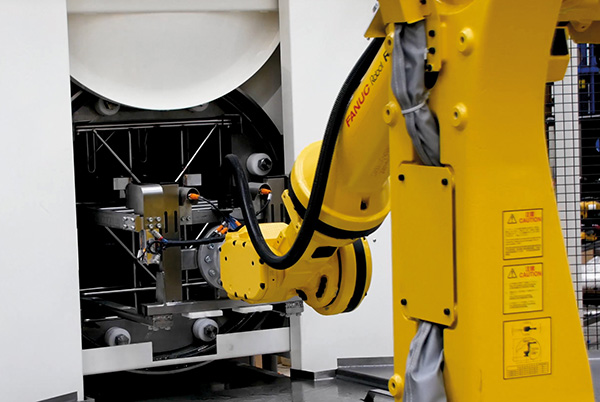

…the company resorted to keeping a week’s worth of inventory on-site, taking up valuable production space and increasing working capital. Yet, despite the time, effort and financial investment in the process, the scrappage rate was still around 11%. On-site automated vacuum impregnation system The company turned to Ultraseal International, a leader in sealing porosity and leak paths in die-cast, sintered, and electrical components. Ultraseal said its engineers worked with the manufacturer to design and install a fully automated, robotic, vacuum impregnation system. The custom system offered fast cycle times, improved productivity, cost-effectiveness, more reliable sealing rates, and improved environmental performance,…

Found in Robotics News & Content, with a score of 3.39

…industry by addressing labor shortages, staff turnover, fulfillment speed, inventory accuracy and even pandemic viruses,” said Craig Wilensky, co-founder and CEO of JASCI Software. “The ability to smartly orchestrate people, robotics and material handling automation in real-time from a single platform, eliminates silos of complicated technology that were previously needed.” Source: JASCI SaaS and RaaS JASCI claimed that it is an innovation leader in warehouse management software as a service (SaaS). It said its SaaS platform is powered by SmartTask, a patented technology that makes it easier to adapt changes, optimize, and implement workflows. The company said its multi-tenant, multi-location…

Found in Robotics News & Content, with a score of 3.01

…cloud to provide on-demand automation for materials handling and inventory management. The system enables businesses to find, track, and move almost anything in any facility, claimed the company. Fetch Robotics said its products and services are deployed in leading distribution, fulfillment, and manufacturing centers around the world, augmenting workforces for increased efficiency and productivity. R15.08 a 'watershed moment' Source: Fetch Robotics In recent years, a growing number of manufacturing, distribution, and fulfillment centers have begun using AMRs for tasks ranging from moving packages between workstations to transporting pallets across a warehouse. However, there was no safety standard specifically designed for…

Found in Robotics News & Content, with a score of 2.91

…units being shipped. Companies are investing in automation for inventory management, procurement, assembly, and transportation, among other applications, said Meili Robots. With more companies buying robots, suppliers are unable to keep up with the growing demand, it added. As a result, businesses will deploy different brands of robots, leading to more diverse technology portfolios. According to the industry report, problems can arise when multiple systems — particularly automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) — are used in the same environment. Coming with different operating systems, these robots may not be able to communicate with one another. This…

Found in Robotics News & Content, with a score of 3.35

…one type of robotics to accommodate different types of inventory and workflows, just like a DC might have more than one type of fixed automation. “I think the future involves distinguishing, within the four walls of your DC, what is the best fit type of automation for different segments of inventory,” said Santagate. “Don’t try to force fit one solution into every segment or scenario.” Match robots to processes Scoping out an appropriate robotics solution requires a solid understanding of order profiles and expected throughput levels, dimensions, inventory days on hand, as well as considering labor availability and productivity expectations,…

Found in Robotics News & Content, with a score of 5.10

…capacity. If your order volume increases, so must your inventory. As orders continue to come in, you’ve got to carry more and more stock. After a certain point, you’re carrying too much inventory and it’s time for a new building, right? Maybe. Mike Myers of ODW Logistics extended the life of his building by increasing his team’s efficiency: more orders, same space. Joanne Hoberg, VP of Solutions and Engineering, NFI: “We reduced time to achieve performance objectives by 90% by minimizing time spent learning processes and the warehouse floor.” We’ve said it before, we’ll say it again: training time matters…