The warehousing industry is a major contributor to the growing demand for robotics, and with new technological advances, the variety of warehouse robots to choose from keeps increasing. This does not exactly make it any easier for warehouses to decide which robot to deploy for specific applications.

The difference between AGVs and AMRs

There are two main types of warehouse robots: automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). The main difference between these two lies in their navigation technologies.

AGVs typically use rail navigation, magnetic tape navigation, or wire-guided navigation to move around a facility, meaning they follow a fixed path. They are most commonly used for the transportation of raw materials such as paper, plastic, rubber, steel, and metal.

AMRs move around the facility autonomously. They do so using technologies such as lidar, machine learning, and the cloud, as well as vision-based navigation. Thanks to their flexibility, they are often used for repetitive tasks that were previously carried out by human workers.

Certain mobile robots can also safely collaborate with humans for goods-to-person applications.

Types of warehouse tasks being automated

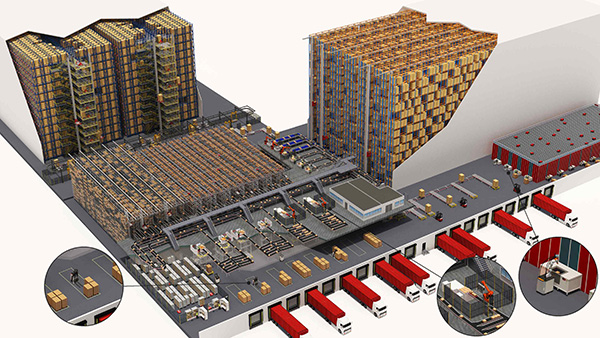

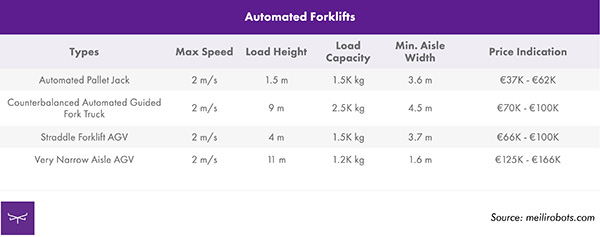

There are several categories of tasks for robots to handle. The first is robots used in transporting goods, from automated lift trucks to heavy load carriers.

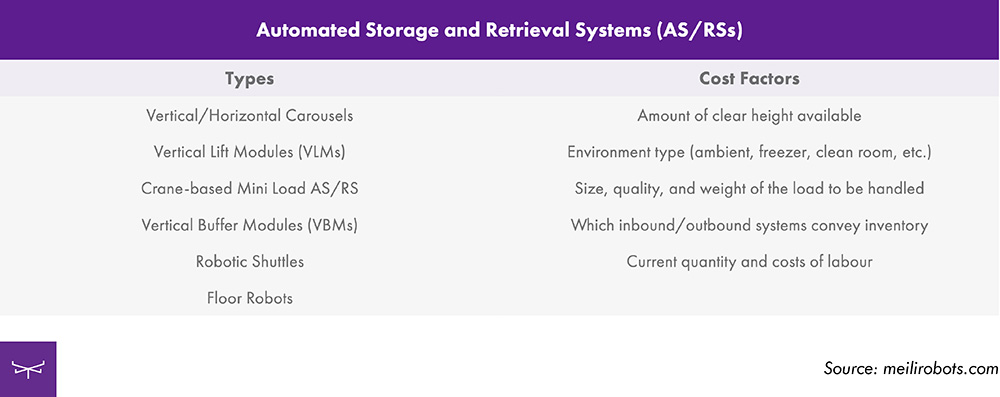

The second is picking, packing, sorting, and storing, including automated storage and retrieval systems (ASRS) and automated guided carts (AGCs).

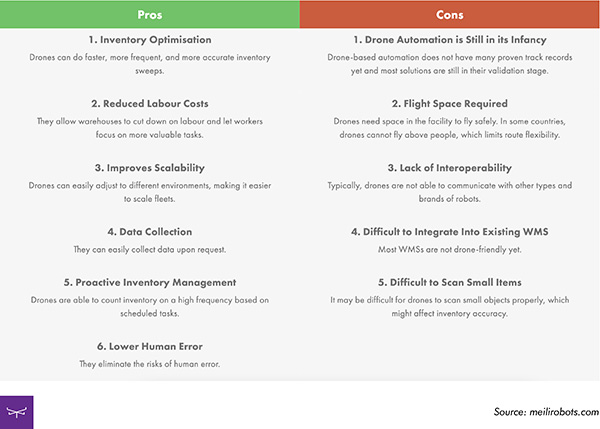

The third task is inventory management, which even includes the use of aerial drones.

Let’s take a closer a look at the eight types of robots that are commonly used in warehouses today.

Which types of robots are best to deploy always depends on the unique circumstances of a warehouse’s operations, facility, and overall goals. This is why we always recommend seeking advice from a specialized supplier or integrator.

About the author

Michelle Schlechtriem is the content manager at Meili Robots. She writes about marketing, technology, and sustainability.

Meili Robots provides a universal fleet management system called Meili FMS. The system is designed to allow robot operators to handle different types and brands of AMRs and AGVs in one system. The fleet management tool can be used for planning, assigning, and executing tasks through key features such as mapping, data logging, and data analytics, said the Copenhagen-based company.

Article topics

Email Sign Up