Editors’ Picks

Found in Robotics News & Content, with a score of 3.34

…The trend up to the [COVID-19] pandemic was just-in-time inventory and to store as little as possible. The assumption was that manufacturers could pump out products and get them to customers as fast as possible. When the pandemic hit, not only were manufacturers struggling to ramp up to meet demand, but they needed overflow space. It changed customer behavior, and they had to pay a bunch more for warehouse space. Does this mean that good data visibility and analytics are as valuable as space? Oliaro: Most of the customers we work with don’t do a good job of managing inventory…

Found in Robotics News & Content, with a score of 3.33

…solution combines hardware and software to provide visibility into inventory and operations. Using 12-metre-tall autonomous robots to capture warehouse data and images in real-time, the digital twin technology enables analysis of stock, occupancy and stock movement. The digital twin then offers instant access to the data captured, highlighting any discrepancies with other warehouse systems in a digital format. The analytics extracted address operational bottlenecks, increase efficiencies (allowing for faster put-away and picking) and provide insights into site operations (for real-time occupancy fluctuation, route planning) - all of which used to be manually done before, the company says. Using AI it…

Found in Robotics News & Content, with a score of 3.32

…reduction Avoid workforce shortages Avoid mistakes Improve traceability and inventory accuracy Layout freedom Modularity or scalability Increased safety Improved ergonomics Minimize infection risk Increase productivity Twenty-three thousand industrial robots are operating in U.K. factories, according to the International Federation of Robotics. The U.K. robot density of 101 units per 10,000 workers is below the world average of 126 units and ranks 24th. This is much lower than most other industrialized countries in Europe and the lowest of the G7 nations. AMRs gain ground When it comes to automation of logistics, autonomous mobile robots are now the largest part of the…

Found in Robotics News & Content, with a score of 3.28

…percent of companies are currently looking to improve their inventory control and lower costs, the company said. Lakestar leads the round, with participation from Maersk Growth, Kindred Capital, and Capnamic. “More than 80% of warehouses have no automation at all,” said Lakestar Partner Christoph Schuh. “With warehouses expected to grow by 50% by 2025 and labor shortages of over 30%, automation clearly holds the key to ensuring logistics operations are as optimized as possible. “Logistics is an industry that always faced margin pressures and little means to invest into a digital infrastructure. BotsAndUs real-time data capture abilities create this infrastructure…

Found in Robotics News & Content, with a score of 3.28

…AS/RS tailored to MAHLE Aftermarket’s material flow, providing enough inventory storage density and processing capability. The complete AutoStore system at the Mississippi facility comprises 42,000 bins, 7 ports, and 18 autonomous mobile robots (AMRs), in addition to a connected conveyor system with 18 gravity lanes used for consolidation. Designed and planned by the team at Kardex, the AutoStore system was built and commissioned on schedule and ramped up quickly and smoothly. “The support provided by Kardex exceeded expectations,” said Rhiannon Fisher, MAHLE Aftermarket head of business excellence for the North America region. “During the design process they were very hands…

Found in Robotics News & Content, with a score of 3.26

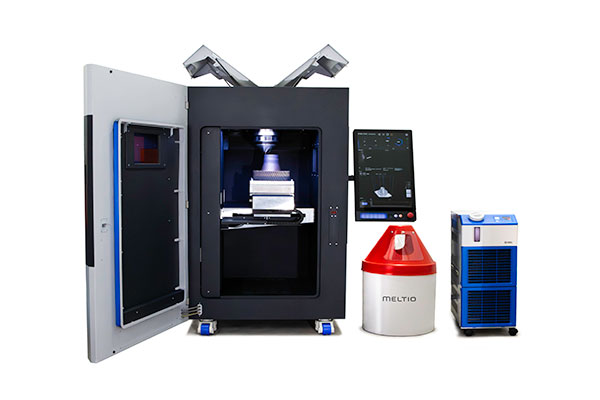

…and manufacturing dependencies by printing parts in-house, reduces warehouse inventory as the raw material can be transformed into the final part on demand and reduces costs by applying material only where it is needed.” While the Meltio M600 is interesting to a broad range of sectors, the company’s goal was to design a system that fits into any machine shop and works alongside CNC machines. This design creates value for the organization, according to Meltio, be reducing material waste and lead times, allowing for more manufacturing flexibility. The company said the M600 works like a machine tool, designed for lights-out…

Found in Robotics News & Content, with a score of 3.25

…ushered into logistics and transportation practices, from tightening up inventory and fulfillment management to elevating the importance of final-mile delivery and returns processes—and everything in between. To respond, logistics professionals now need to leverage diverse systems and new ways of thinking in an effort to improve carrier partnerships and increase speed and efficiency. With that in mind, the editorial staff of Logistics Management (a sibling site to Robotics 24/7) has put together a collection of features to help readers push that pace of change inside their organizations. Contributing editor Roberto Michel offered shippers a high-level look at the role that…

Found in Robotics News & Content, with a score of 3.25

…Geek+ said its robots and software provide the 360° inventory oversight that the strategy requires. It has deployed a fully automated, flexible, multi-robot system that it claimed “represents a breathrough in intelligent manufacturing.” Beijing-based Geek+ said it applies autonomous mobile robots (AMRs) and artificial intelligence to warehouse and supply chain management. Siemens Switchgear first joined forces with Geek+ in 2019. It successfully automated logistics with four models of Geek+ robots: the P800R goods-to-person picking robots, the MP1000R AMRs, the RS2 totes-to-person robots, and the X-series four-way shuttles for high-density storage. The electronics components maker said its entire process is now…

Found in Robotics News & Content, with a score of 3.24

…workflow selections were stored in a single, digital production inventory. The next focus for the development will be machine connectivity that includes documentation of production parameters and a software evaluation of that data for quality assurance. Pushing Towards Agile Manufacturing The company says Agile MES enables additive manufacturing facilities to benefit from digital production planning and software driven workflows to improve efficiency and machine utilization. The next focus will be finalizing machine connectivity. To learn more about the 3YOURMIND MES for Additive Manufacturing, click here. Watch the 3YOURMIND introductory video. Read about the five problems 3YOURMIND solves related to 3D…

Found in Robotics News & Content, with a score of 3.23

…[6RS] in our lab. We built a micro-warehouse with inventory, installed a WMS [warehouse management system], and created our SVT/Shopify robotics store. [Editor's note: Shopify acquired 6RS in 2019.] We bought boxes of ramen and put them on the shelves. Now, when someone gets a 6RS demo, they can place an order, and next thing you know, the robots are moving. They can help pick it, and the visitor can get an e-mail that the order is complete. A customer can see all the workflows, ending with the picked order and confirmation. We're showing this experience from the consumer point…

Found in Robotics News & Content, with a score of 3.23

…totes and cartons. These are stored densely in an inventory area using pallets or mobile racks of 3.7 m (12.1 ft.) height for 50% more storage density compared with its predecessor. One rack can store up to 60 totes and be customized to store goods of varying sizes in an optimized way allowing four times more transportation efficiency, said the company. Once incoming orders are registered, picking robots transfer pallets or mobile racks to a PopPick station, where intelligent robot arms effectively retrieve totes or boxes of ordered goods and give them to the operator in two picking points. This…

Found in Robotics News & Content, with a score of 3.22

…operations. This empowers businesses to spend less time managing inventory and more time focusing on ensuring continued success, according to Pio. By providing an entry point to warehouse automation for a relatively low investment, small businesses can keep their operations in-house instead of requiring a third-party logistics provider (3PL) or significant real estate and labor investments to scale up, it said. “Never before has the option for a fully automated storage and retrieval system [ASRS] been offered to the SMB segment—and certainly not with robotic technology that has been proven through multitudes of successful installations around the world for over…