Editors’ Picks

Found in Robotics News & Content, with a score of 3.66

…carts, helping to free up space, increase flexibility, and gain advantages more quickly. AMRs improve employee morale, retention DENSO employees were walking up to 12 miles per day moving material between production areas and the warehouse, spending about 60% of their time just pushing carts, said Olinger. The initial pilot program to automate this conveyance with AMRs eliminated this manual task, allowing six workers to transition to more value-added work, he noted. The project quickly expanded to bring components directly to line-side production for just-in-time efficiencies. Support for the robots has grown quickly among employees, with workers in other departments…

Found in Robotics News & Content, with a score of 3.65

…that will allow them to set the standard and gain considerable advantages.” Founded in 2015, Geek+ applies robotics and artificial intelligence to efficient warehouse systems and supply chain management. The Beijing-based business has 1,500 employees and 300 global customers and said it has deployed more than 20,000 autonomous mobile robots (AMRs) worldwide. Geek+ recently won a 2021 Supply Chain Excellence Innovation Award for its robotic sorting system, alongside Asda Logistics Services and AMH Material Handling. CEVA Logistics searched for solutions CEVA Logistics is a global third-party logistics provider (3PL) with more than 78,000 employees working across 10 regional clusters around…

Found in Robotics News & Content, with a score of 3.63

…(AMR). They will receive a dedicated Seegrid team and gain exclusive opportunities to experience and provide feedback on the new technology. STEP participants will also obtain insights into product roadmaps and be able to affect the direction of innovations like the Palion Lift that are designed to address major supply chain challenges. “Supply chain pressure is at an all-time high, and Seegrid Palion Lift will become a critical part of our customers’ operations,” stated Jim Rock, CEO of Seegrid. “STEP puts Palion Lift into select customers’ live production environments now, and [it] provides companies participating in the program the ability…

Found in Robotics News & Content, with a score of 3.63

…manufacturing verticals.” Companies are increasingly turning to robotics to gain competitive advantage in the supply chain, with adoption expected to rise from 34 to 73 percent over the next five years, according to a survey in the 2018 Material Handling Institute’s annual report. The study identified that the most common uses for robotics in warehousing operations include tasks like receiving and putting away inventory. Honeywell Intelligrated provides automation equipment, software and services to more than 60 of the top 100 global retailers and half of the top 100 internet retailers. Distribution centers can deploy the business’s Momentum warehouse execution system…

Found in Robotics News & Content, with a score of 3.62

…worker travel and lifting strain. This approach will help gain acceptance from the workforce that robots are good for them.” Pitching productivity A total of 75% of workers said the introduction of robots would help, rather than impede, them from doing their jobs, Lucas Systems said. If technology can make it easier for workers to do their jobs, accuracy and productivity should increase while also reducing worker stress, the company said. “We have seen productivity improvements well over 40% from working with the Jennifer voice system from Lucas,” it added. “Robotics scenarios where AMRs do the long-haul travel, while workers…

Found in Robotics News & Content, with a score of 3.61

…replenishment or eCommerce order fulfillment,” said Fisher. “Customers will gain modular and flexible robotics options to help them increase speed and throughput of their operations as well as sophisticated analytics with Honeywell’s Momentum Warehouse Execution Software to run their businesses optimally.” Tompkins has more than 30,000 robots, such as its tSort and PickPal AMRs, and more than 300 installations at companies across the globe. Honeywell said Tompkins’ AMRs enable businesses to use space effectively, from small back-of-store operations to large distribution centers, and deploy automation rapidly. They also make it easy for companies to scale quickly as they take on…

Found in Robotics News & Content, with a score of 3.61

…and the application of artificial intelligence, robotics users could gain timely insights into critical processes. Data collected from stationary and mobile sensors and analyzed with AI could drive greater efficiency, flexibility, and productivity, said Meili. “A few companies have tried using robots from more than one vendor,” von der Burg told Robotics 24/7. “They want to avoid bottleneck inefficiencies. One pharmaceutical firm has been using AGVs and is looking to diversify its fleets with AMRs and robots for outdoor deliveries.” The report includes a case study about Project START, which involved testing and adjusting Mobile Industrial Robots ApS's fleet management…

Found in Robotics News & Content, with a score of 3.61

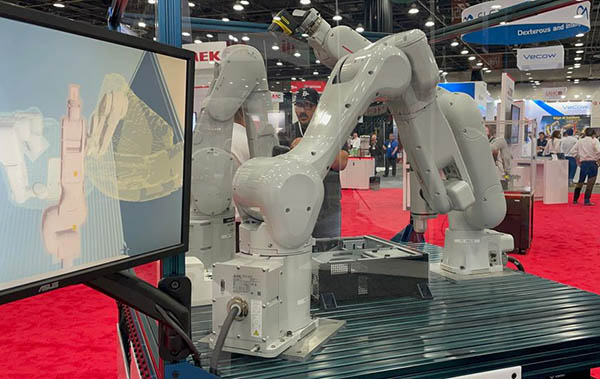

…software enables major cost savings, flexibility, and process efficiency gains at the world’s largest and most sophisticated robotics installations,” stated Jeffrey Smith, general partner at SIP Global Partners. “Seamless programming, automated rollout, and conflict resolution will drive large-scale adoption and ROI. We look forward to working closely with Realtime as they deploy their uniquely innovative solutions globally.” Realtime Robotics said it will apply the new funds to continue to scale and meet growing industry demand for RapidPlan. It also plans to invest in overall engineering development and to enable additional enhancements to its core software. Realtime recently demonstated RapidPlan's ability…

Found in Robotics News & Content, with a score of 3.60

…said that service robots will provide efficiency and productivity gains that will allow businesses to allocate more time and resources for staffers to refocus on customer service. “We are proud to partner with SoftBank Robotics, the leader in the robotics solutions industry,” stated Tony Li, CEO of Keenon Robotics. “As the cost of labor increases, technology becomes an affordable solution, creating an increased appetite for automation alongside human tasks. The Keenbot is one such example of a solution that is meant for convenience and performs well when completing repetitive operational tasks that require precision.” Keenon Robotics a leader in service…

Found in Robotics News & Content, with a score of 3.60

…David Lincoln, managing partner at Activate Capital. “We believe Fictiv is the category leader transforming how companies like Honeywell gain unmatched productivity, efficiency, and enterprise scalability through digitized workflows that dramatically change the speed and quality of manufacturing in markets such as energy, healthcare, space, and transportation,” Lincoln said.

Found in Robotics News & Content, with a score of 3.59

…she said. Plug-and-play connectivity With CGConnect, remote users can gain instant access to Cloud Ground Control’s rich features, including real-time telemetry, cloud storage, video, and payload data. They can get them all from a Web browser simultaneously, the company said. Weighing only 55 grams with similar sizing to a credit card, CGConnect is easily integrated into any product design. Cloud Ground Control said it offers the following benefits: Open platform— The flexible and customizable platform operates on the MAVLink standard. This multiplies potential product applications and enables diverse autonomous vehicles and payloads to operate as a coordinated fleet. Robotic-agnostic—It works…

Found in Robotics News & Content, with a score of 3.57

…“In order to disrupt the industry again … and gain traction, we need a sustainable difference and superior economics to compete with mass production,” says Dr. Tim Weber, global head of HP’s metals 3D printing business. With its price point starting at around $399,000, HP is making a strong economic case for the Metal Jet as a serious alternative for mass production. For a part such as a valve train roller finger follower for cylinder shutoff, HP says the break-even point for using the Metal Jet over competing technologies like metal injection molding or laser 3D printing is 55,000 parts…