For robots to be useful in a widening range of applications, motion planning needs to be as straightforward as possible. Realtime Robotics Inc. today said it has secured $14.4 million in additional funding. The company recently launched its RapidPlan software, which is designed to help manufacturers design and deploy industrial automation faster and more efficiently.

“We have seen a tremendous industry response to the launch of RapidPlan and its ability to make collision-free operations a reality for industrial robotics, speeding programming time and increasing throughput,” said Peter Howard, CEO of Realtime Robotics. “We’ve recently pivoted away from hardware to pure software, making it even easier for all customers and partners to integrate our revolutionary technology within their existing stack and workflows. This latest round of funding will assist us in scaling to meet demand.”

Boston-based Realtime Robotics said its technology generates collision-free motion plans in milliseconds for industrial robots and autonomous vehicles. The company claimed that its system empowers robots to function together in unstructured and collaborative workspaces, as well as to react to dynamic obstacles the instant changes are perceived.

Motion planning the key to warehouses automating

More than 80% of warehouses today lack any type of automation, according to Acumen Research and Consulting. In addition, robotics adoption in warehouses will increase by more than 50% over the next five years, reports the Material Handling Institute.

The Association for Advancing Automation (A3) found that robot sales had their strongest year ever in 2021, and three consecutive quarters of growth this year.

“There is a massive market opportunity available,” noted Realtime Robotics. “Technology that can help streamline and optimize the use of industrial robotics in both logistics and manufacturing will be critical to companies looking to quickly drive ROI from their new robotics investments.”

RapidPlan eases robot choreography

With RapidPlan, customers in the automotive and other industries can automate the programming, deployment, and control of their robots, said Realtime Robotics. Users can autonomously create and choreograph all robot movements without the need for brand-specific robot programming, it explained.

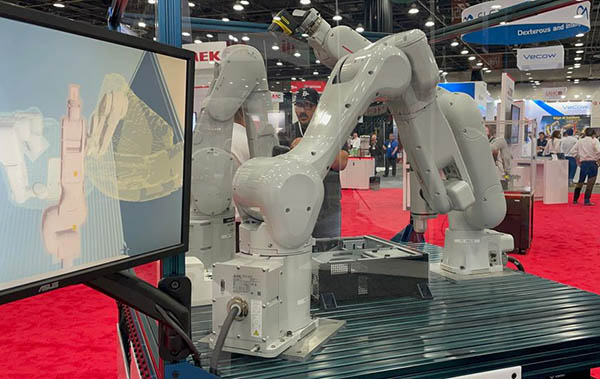

Within RapidPlan’s software, users create digital twins of their workcells and then simply point and click on robots and target points to visualize collision-free task plans, saving weeks to months of programming time per project, said Realtime. The same software used for the simulation environment then controls the real-world robots.

“Watching Realtime Robotics’ software guide robot motions was a thing of beauty,” said Greg Tormanen, automotive body in white engineering manager at Kawasaki Robotics Inc. “The robots were interacting with each other and were not crashing.”

“It has taken operators years of practice to become skilled enough to make robot motion and planning both efficient and effective,” he added. “Realtime’s technology decreases the amount of time it takes to perform the task, enabling those with less experience to realize the same results. This level of interaction is simply impossible with human programming.”

Realtime Robotics to invest in scaling up

Soundproof Ventures, Heroic Ventures, and SIP Global Partners were the lead investors in Realtime Robotics' latest funding. The company raised $31.4 million in Series A funding in June 2021.

“As supply chains are increasingly taxed, industry craves efficiency,” said Michael Silverstein, managing partner of Soundproof Ventures. “By automating the most challenging and costly aspects of operating industrial robots, Realtime Robotics enables customers to unlock the promise of automation and drive output well beyond what has ever been conceived.”

“Realtime Robotics’ motion-control software enables major cost savings, flexibility, and process efficiency gains at the world’s largest and most sophisticated robotics installations,” stated Jeffrey Smith, general partner at SIP Global Partners. “Seamless programming, automated rollout, and conflict resolution will drive large-scale adoption and ROI. We look forward to working closely with Realtime as they deploy their uniquely innovative solutions globally.”

Realtime Robotics said it will apply the new funds to continue to scale and meet growing industry demand for RapidPlan. It also plans to invest in overall engineering development and to enable additional enhancements to its core software.

Realtime recently demonstated RapidPlan's ability to help organizations optimize their robot programming and deployment, thereby improving their efficiency and effectiveness at the Automate 2022 conference. It will again display its technology with Kawasaki and Mitsubishi Electric Automation at the International Manufacturing Technology Show (IMTS) next week in Chicago.

Article topics

Email Sign Up