The Panama Canal – which handles 5 percent of the worldwide shipping trade – marked its 100th anniversary this summer.

Today, the Panama Canal is in the midst of a massive $5.25 billion expansion project to meet global transportation and commerce needs into the next century.

Alan Krause, chairman and CEO of MWH Global, a premiere solutions provider focused on water and natural resources, discusses how engineering, sustainable design and technology are intersecting at this historic waterway.

The Panama Canal remains one of the world’s greatest engineering feats. What is your firm’s role in the current expansion of the Panama Canal to accommodate larger cargo ships?

MWH is proud to be designing a part of history. We’re leading the technical design for the third set of locks, the largest portion of the Panama Canal expansion project.

The new locks, which are expected to be open for traffic in 2016, will double the canal’s capacity, providing significant benefits to local, regional and global economies.

Why is the Panama Canal expansion project so critical to meeting the world’s transportation needs today and in the future?

Water is one of the world’s most precious resources, and it’s also the backbone of global trade.

For a century, the Panama Canal has been a gateway for getting goods to people in ways that are quicker and cost-effective.

However, today’s post-Panamax ships are currently too wide and too long for the Panama Canal locks.

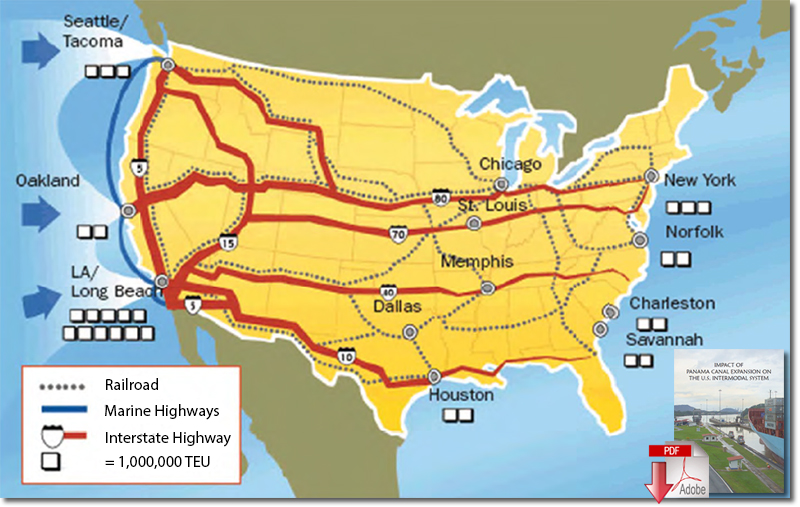

Those larger cargo and container ships have to find alternative routes. Some travel to the U.S. East Coast via the Suez Canal, others transfer their cargo on the U.S. West Coast where it is taken by train, others drop their cargo at one end of the Panama Canal to be transported by train to the opposite end, and still others dock at a U.S. port and use intermodal transportation to transport their cargo from one side of the U.S. to the other.

Once the new Panama Canal locks are open, the wider locks will accommodate these post-Panamax ships, which can carry three times as many cargo containers as ships that can now pass through the canal.

Using the expanded canal will lead to lower transportation costs and reduced carbon emissions, and the new locks will operate in more efficient and sustainable ways, including reducing water consumption per ton of cargo transited.

At the same time, the Panama Canal expansion is also having ripple effects in other major coastal cities, as their port infrastructure is being or will need to be upgraded to handle the larger ships and additional container traffic.

U.S. West Coast Gateways and Corridors Effected by the Panama Canal Expansion

Source: U.S. Department of Transportation, Maritime Administration

What were the biggest technical design-related challenges your team faced and how did you use technology to solve these?

The third set of locks project includes two massive lock facilities – one on the Atlantic side and another on the Pacific, each with three chambers. One of the most innovative and challenging design elements was the large water basins that will save and reuse 60 percent of the fresh water used in the lock system.

Using 3D computer modeling, cloud computing to connect teams and a physical scale model (1:30, over 200 feet long) our engineers had to determine the best way to optimize these water-saving basins to address varying water levels and improve the filling and emptying times of the locks while allowing safe transit of the much larger ships that will pass through.

The design is a first for a project of this size, and it’s especially critical for a country that needs to conserve fresh water resources used for water supply and hydroelectric power. In addition, the new locks have a total of 16 rolling gates, eight each for the Atlantic and Pacific lock facilities. Unlike the current canal, which uses gates that swing open across half the lock, the expanded canal will have rolling gates that move across the entire lock lane.

The design of the lock heads and lock gates required the use of super computers to model their dynamic interaction under large seismic loads. In fact, the locks gates – the largest in the world, each weighing between 3,000-4,000 tons and standing 11 stories tall – were shipped four at a time from Italy across the Atlantic Ocean to Panama. That was quite the global maritime transportation feat in itself.

Engineers around the world collaborated on the technical design for the new Panama Canal locks and construction plans. How did they stay connected?

We used leading technology to integrate our global team of engineers, project managers and experts, allowing us to gain time and cost efficiencies while tapping the best minds across many time zones.

Our Building Information Modeling, or BIM, software from Autodesk provided 24/7 options for collaborating on the lock design, managing technical design changes, and coordinating all design and construction documents among our teams on four continents.

Seamless collaboration and real-time problem solving also helped us adhere to the stringent technical requirements and specifications established by the Panama Canal Authority, which oversees and operates the canal.

What megatrends do you foresee shaping other infrastructure projects like the Panama Canal in the future?

Megatrends like climate change, scarcity of resources and technology are driving our focus on finding and designing sustainable solutions that help us achieve our bigger purpose of building a better world. For example, water scarcity is both natural and human-made. There may be enough freshwater on the planet for 7 billion people, but it’s unevenly distributed and too much is wasted, polluted or unsustainably managed.

That creates a huge infrastructure need and challenge for us. When it comes to climate change, there’s an increased frequency and intensity of severe weather events worldwide. More frequent floods and droughts affect water quality and availability. Rising seas contribute to greater coastal erosion or flooding. Warmer temperatures boost energy usage.

It’s all interconnected, and we’re seeking to help communities better predict, mitigate and recover from these issues. Finally, new data management tools and technology are disrupting the status quo in how we do business and serve our customers.

For example, predictive analytics tools help us make sense out of big data and create tremendous ROI for municipalities that need to make smart investments in when, where and how to replace their aging infrastructure from roads to sewer pipelines. Our people are passionate about tackling these types of complex issues that impact our everyday lives and future.

Source: HP Matter

Related: Panama Canal Expansion - Questions Mount as Time Draws Near

Article topics

Email Sign Up