Editors’ Picks

Found in Robotics News & Content, with a score of 72.04

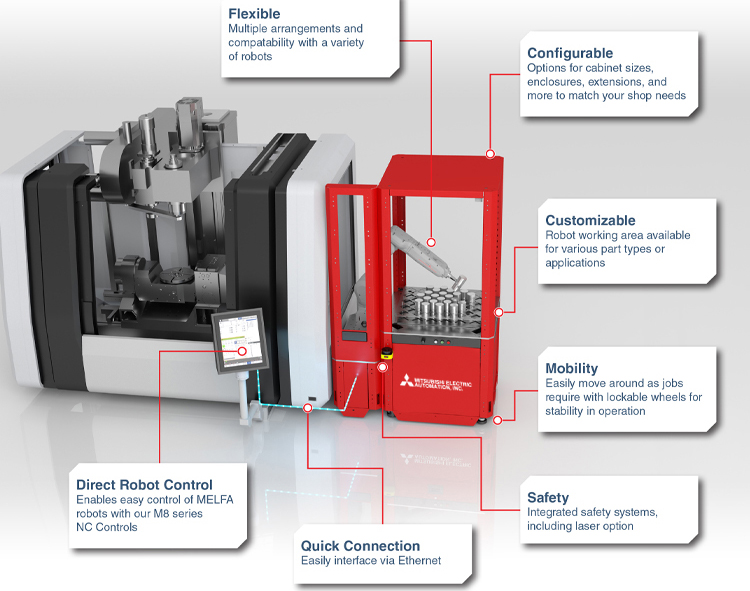

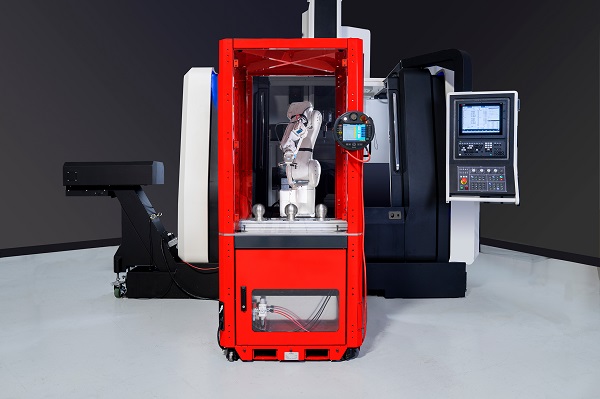

…automation. Mitsubishi Electric Automation Inc. this week launched a machine tending offering for its LoadMate Plus product line that it said is easy to implement. Mitsubishi Electric Automation claimed that its machine tending systems can improve productivity and reduce operating costs. The LoadMate Plus product line also offers flexibility and mobility to address skilled labor shortages in manufacturing, it said. “Mitsubishi Electric Automation Inc.’s machine tending solutions portfolio provides a cost-effective answer to ongoing labor shortages and maximized productivity challenges many manufacturers are currently experiencing,” said Dave Simak, service product manager at Mitsubishi Electric, in a press release. “Our experts…

Found in Robotics News & Content, with a score of 66.79

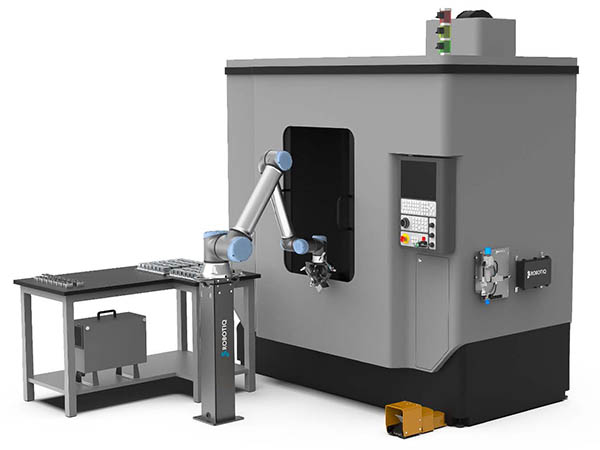

…today said at Automate 2022 here that its new Machine Tending Application Solution will make collaborative robots more accessible than ever. The Lévis, Quebec-based company said its system can reduce implementation costs by up to 50% and takes less than two hours to go from unboxing to machining the first part—with no coding experience required. “When a machine shop owner struggles to find employees to do the work, their first instinct is to look for new CNC machines that can run unattended for longer and with shorter changeover times,” said Samuel Bouchard, CEO of Robotiq. “But those machines are costly,…

Found in Robotics News & Content, with a score of 54.25

…will “add new levels of flexibility to high-mix, low-volume machine tending automation,” said the company. Beta testers including customers and partners provided valuable feedback throughout the development of PolyScope X, said Universal Robots. The collaborative robot leader showed a prototype at the International Manufacturing Technology Show (IMTS) last year. Anders Billesø Beck. Source: Universal Robots “PolyScope X is a perfect example of how we approach innovation at Universal Robots,” said Anders Billesø Beck, vice president for strategy and innovation at the Odense, Denmark-based company, in a blog post. “We want to include our partners and end customers right from the…

Found in Robotics Companies & Businesses, with a score of 53.50

Yaskawa Motoman delivers innovative robotic automation solutions for virtually every industry and robotic application, including arc welding, assembly, coating, dispensing, material cutting (laser, plasma, waterjet), material handling (diecast, machine loading, packaging, palletizing, part transfer, press tending), material removal (deburring, polishing, sanding) and spot welding.

Found in Robotics News & Content, with a score of 50.61

…that face labor shortages for CNC (computer numerical control) machine applications can benefit from the LoadMate Plus, said Mitsubishi Electric. The robot cell can provide flexibility for traditionally high-mix, low-volume facilities to introduce automation, according to the company. LoadMate Plus automates the task of loading and removing parts from a machine tool through the use of robotics. It can be mounted next to one machine or between two machines and otherwise moved around a facility as jobs require. When this cell is paired with Mitsubishi Electric M8 Series CNC, operators can use the Direct Robot Control (DRC) feature within the…

Found in Robotics News & Content, with a score of 47.67

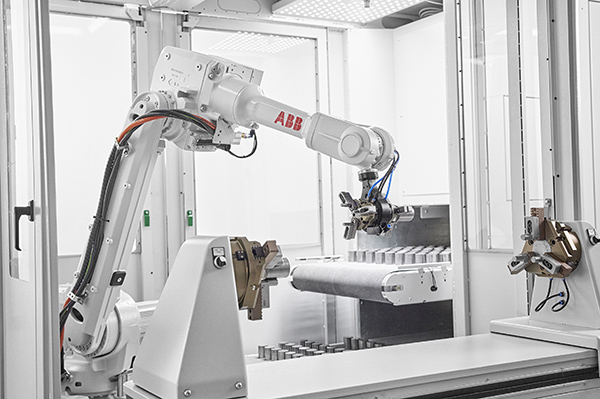

ABB has launched a new family of modular machine-tending application cells for the metals industry aimed at maximizing flexibility and machine utilization while minimizing lost productivity caused by unforeseen production stoppages. Featuring six different versions, the FlexLoader M family offers a variety of ways of loading and unloading machines based on the size, shapes, and amount of the workpieces being handled. This makes it ideal for applications such as foundries and die-casting operations producing multiple types of products in varying quantities, ABB said. “As customers demand greater variety and shorter delivery times, metals producers need to have a manufacturing process…

Found in Robotics News & Content, with a score of 46.78

…Inc. will be celebrating 50 Years of supporting the machine tool industry in North America at the International Manufacturing Technology Show (IMTS) 2024. IMTS 2024 will be held Sept. 9-14 at McCormick Place in Chicago. Mitsubishi Electric will showcase its latest automation and machining systems through interactive demonstrations at booth 338136 in the South Building “We are excited to be celebrating 50 years of supporting the machine tool industry with our new and existing customers,” said Scott Strache, Mitsubishi Electric Automation senior product manager for mechatronics. “To uphold our quality, performance, and compatibility promises, we proudly support and service past…

Found in Robotics White Papers & Archives, with a score of 44.95

…and precision are also changing how tasks such as machine tending, packaging, and welding are done. However, many small and midsize enterprises (SMEs) are reluctant to invest in systems for high-mix, low-volume applications. Integrators must evaluate the latest sensors, software, and end effectors for different use cases. In addition, researchers, integrators, and end users must consider the level of interaction with human co-workers, environmental conditions, and the safety of different payloads. In this Special Focus Issue, we consider how cobots have become a fast-growing segment of automation and how suppliers are turning their focus to specific applications. This free download…

Found in Robotics News & Content, with a score of 43.89

…limited floor space, and the slim arm fits into machine tools to load and unload parts, said the company. “The new LR-10iA/10 is a great solution to help manufacturers and distribution centers overcome obstacles associated with labor shortages, while improving throughput and reducing operating costs,” said Eric Potter, general manager of FANUC America’s General Industries and Automotive Segment. FANUC America is a subsidiary of Japan-based FANUC Corp. in Japan. The Rochester Hills, Mich.-based company said it provides CNC (computer numerical control) systems, robotics, and factory automation to help manufacturers maximize productivity, reliability, and profitability. LR-10iA/10 designed for flexibility Weighing 46…

Found in Robotics Companies & Businesses, with a score of 42.90

…to make it easy to deploy collaborative automation for tasks such as such as packaging, quality control, materials handling, machine tending, assembly, and surface finishing, regardless of skill level or previous robotics experience.

Found in Robotics News & Content, with a score of 42.72

…A/S to automate Polar’s press brake application. The URe-based machine-tending system can produce 750 parts in 10 hours, which will save Polar about $77,000 a year in labor costs. Polar can monitor performance from Formic’s platform, which delivers analytics in real time. Formic guarantees reliability with RaaS “It’s been very painless,” said Bob Albert, owner of Polar. “We like the company we chose. They don’t just set us up and walk away. And that to me is very key. They charge us by the hour for the machine, which is a very novel approach.” “And if the machine’s not running,…

Found in Robotics News & Content, with a score of 39.57

…Attendees are able to see the latest in robotics, machine vision, artificial intelligence (AI), and motion control. Grippers for CNC machine tending OnRobot said a stronger end-effector, or end-of-arm tooling (EOAT) platform for industrial robots deployed in collaborative applications enables improved workpiece adaptability. The company’s new grippers offer an all-round plug and produce experience, including fingers with multiple configurations, flange adapters, cabling, and software that removes complexity of robot programming, said OnRobot. “As cobots grow more powerful, OnRobot customers are scaling up their collaborative applications,” says Enrico Iversen, OnRobot CEO. “Building on the success of our existing, industry-proven gripper range,…