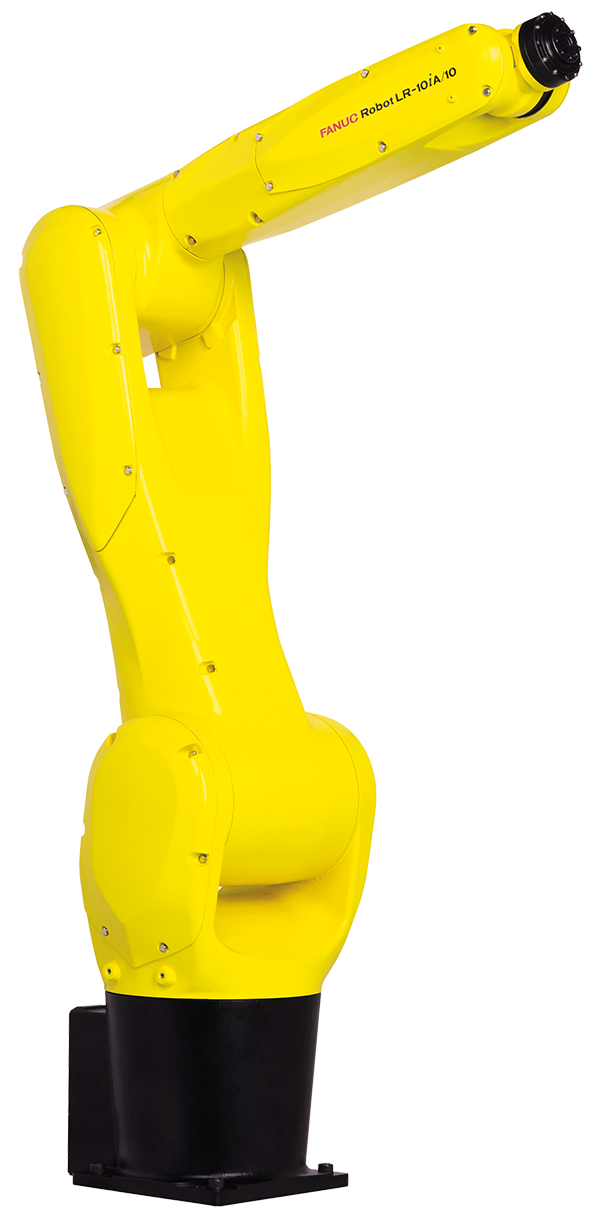

FANUC America Corp. yesterday introduced its new LR-10iA/10 robot, which can be mounted to the floor, upside down, or on an angle. Its compact size makes it suitable for companies with limited floor space, and the slim arm fits into machine tools to load and unload parts, said the company.

“The new LR-10iA/10 is a great solution to help manufacturers and distribution centers overcome obstacles associated with labor shortages, while improving throughput and reducing operating costs,” said Eric Potter, general manager of FANUC America’s General Industries and Automotive Segment.

FANUC America is a subsidiary of Japan-based FANUC Corp. in Japan. The Rochester Hills, Mich.-based company said it provides CNC (computer numerical control) systems, robotics, and factory automation to help manufacturers maximize productivity, reliability, and profitability.

LR-10iA/10 designed for flexibility

Weighing 46 kg (101 lb.), the LR-10iA/10 robot is easy to mount on an automated guided vehicle (AGV) or another mobile platform to accommodate a variety of repetitive tasks or automate machines that are standing idle, FANUC America said.

The new industrial robot arm has a 10 kg (22 lb.) payload and a work envelope with a reach of 1,101 mm (43.3 in.). The LR-10iA/10 can be used for machine tending and a variety of picking applications found in the warehousing and logistics markets, according to FANUC.

In addition, a fully enclosed structure features built-in air lines, solenoid valves, and electrical utilities for easy integration, said the company. The LR-10iA/10 has an IP67 rating, so it can operate in industrial environments with dust, water, and oil mist.

FANUC said that the LR-10iA is powered by the FANUC R-30iB Mate Plus controller, offering the same intelligence and reliability available as all of its robots. It includes integrated iRVision, force sensing, and Zero Down Time (ZDT).

Not only can ZDT reduces unexpected downtime, but it can also help users maximize production throughput, optimize maintenance costs, increase the life of their robots, and access data from anywhere via the ZDT Web portal, said FANUC.

New FANUC robot features

FANUC said its LR-10iA/10 has the following features:

- Smooth and clean surface with internal valves, built-in user airlines, solenoid valves, and I/O signals.

- Slim, lightweight, and compact for quick and easy installation – even on AGVs.

- Strong wrist with high payload, moment, and inertia.

- 10 kg payload with full work envelope; can handle 13 kg (28.6 lb.) with restricted envelope.

- Fully enclosed design with standard IP67 rating.

- Designed for machine load/unload and part picking.

FANUC plans to begin shipping production units of the new LR-10iA/10 in January 2022.

Article topics

Email Sign Up