Editors’ Picks

Found in Robotics News & Content, with a score of 14.67

…to program and apply to different tasks, such as machine tending or welding. The global market for cobots will grow from $590 million in 2020 to $1.9 billion by 2030 at a compound annual growth rate (CAGR) of 12.3%, predicted Research and Markets. Mordor Intelligence was similarly bullish, forecasting a CAGR of 18.37%, from $668.3 million in 2020 to $1.8 billion in 2026. Universal Robots claimed that it introduced “the world's first commercially viable” collaborative robot in 2008. Since then, the company has installed more than 50,000 cobots worldwide, representing a fast-growing niche in industrial automation. Universal Robots' product portfolio…

Found in Robotics News & Content, with a score of 8.56

…increasingly sophisticated. Cobots have shifted from pick-and-place operations and machine tending to also being process tools. With the e-Series precision and torque, plus partner software for welding and screwdriving, our partners are driving a lot of innovation with us. Cobot awareness grows Given the market potential, do SMEs have a greater awareness of the potential benefits of using cobots? Povlsen: Yes, absolutely. We do our market analysis, and we know that there are tens of millions of tasks that people could do for more value-added work than the “3 Ds” [dull, dirty, and dangerous]. We're still just scratching the surface…

Found in Robotics News & Content, with a score of 25.26

…The company focuses on material handling, automated assembly, and machine vision applications “that augment human labor and fulfill the promise of Industry 4.0.” Futura Automation has offices and representatives across the U.S. and in Queretaro, Mexico. Futura Automation will be READY's stocking distributor for states including Arizona, California, Idaho, Iowa, Kansas, Louisiana, Minnesota, Missouri, Montana, Nevada, North Dakota, Oklahoma, Oregon, South Dakota, Texas, and Washington. “Futura Automation provides innovative solutions for tough manufacturing problems. Our team is focused on helping our customers compete in global markets and allow reshoring of production using automation tools such as robots, machine vision and…

Found in Robotics News & Content, with a score of 18.35

…in the areas of programmable logical controllers (PLCs), PCs, human-machine interfaces (HMIs), motion control, machine vision, safety light curtains and scanners, structural guarding, and workstations. Berkeley Heights, N.J.-based The Knotts Co. works with manufacturers of industrial, automation, and robotics products. Knotts collaborates with customer experts to create higher-level solutions including technology, products, integration, machine-building, and other services for increasing performance, productivity, and profitability. Electromate in Vaughan, Ontario, is known for its high-performance robotic and mechatronic systems. It has been recognized as one of the best workplaces in Canada for multiple years and is a recipient of the Canadian Business Excellence…

Found in Robotics News & Content, with a score of 42.72

…A/S to automate Polar’s press brake application. The URe-based machine-tending system can produce 750 parts in 10 hours, which will save Polar about $77,000 a year in labor costs. Polar can monitor performance from Formic’s platform, which delivers analytics in real time. Formic guarantees reliability with RaaS “It’s been very painless,” said Bob Albert, owner of Polar. “We like the company we chose. They don’t just set us up and walk away. And that to me is very key. They charge us by the hour for the machine, which is a very novel approach.” “And if the machine’s not running,…

Found in Robotics News & Content, with a score of 19.03

…packaging, quality control, and materials handling, as well as machine tending, assembly, and surface finishing. WebLytics uses OEE standard Not only can WebLytics eliminate manual data collection for cobot end users and integrators, but it can also provide actionable insights into how well a collaborative application is performing, claimed OnRobot. The software is also designed to offer live device diagnostics, alerts, and preventive-maintenance measures to minimize costly robot cell downtime, it said. Integrating the globally recognized Overall Equipment Effectiveness (OEE) industry standard, WebLytics identifies trends in the robot cell, including patterns, peaks, and disturbances in application productivity. OEE measures the…

Found in Robotics News & Content, with a score of 43.89

…limited floor space, and the slim arm fits into machine tools to load and unload parts, said the company. “The new LR-10iA/10 is a great solution to help manufacturers and distribution centers overcome obstacles associated with labor shortages, while improving throughput and reducing operating costs,” said Eric Potter, general manager of FANUC America’s General Industries and Automotive Segment. FANUC America is a subsidiary of Japan-based FANUC Corp. in Japan. The Rochester Hills, Mich.-based company said it provides CNC (computer numerical control) systems, robotics, and factory automation to help manufacturers maximize productivity, reliability, and profitability. LR-10iA/10 designed for flexibility Weighing 46…

Found in Robotics News & Content, with a score of 24.17

…packaging, quality control, and materials handling, as well as machine tending, assembly, and surface finishing. Learn OnRobot designed for easy reference Learn OnRobot provides step-by-step guidance for tasks using the company's grippers, vision cameras, processing kits, and sensors in setups with all major cobot and light industrial robot brands, said OnRobot. Localized with support in nine languages, the platform includes an extensive library of “How To” videos and 3D simulations with detailed information on collaborative applications, including machine tending, palletizing, pick and place, and sanding. Learn OnRobot is accessible via PCs, smartphones, and tablets for easy access to resources from…

Found in Robotics News & Content, with a score of 47.67

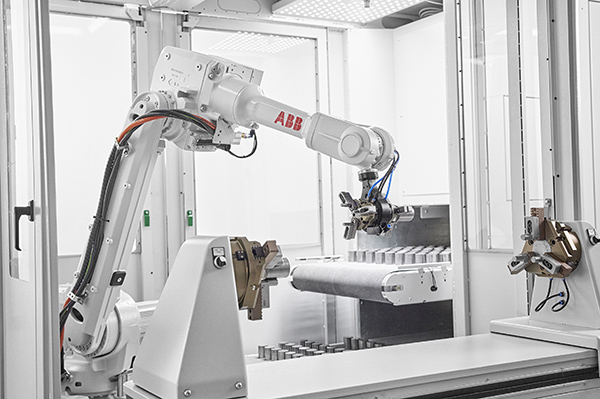

ABB has launched a new family of modular machine-tending application cells for the metals industry aimed at maximizing flexibility and machine utilization while minimizing lost productivity caused by unforeseen production stoppages. Featuring six different versions, the FlexLoader M family offers a variety of ways of loading and unloading machines based on the size, shapes, and amount of the workpieces being handled. This makes it ideal for applications such as foundries and die-casting operations producing multiple types of products in varying quantities, ABB said. “As customers demand greater variety and shorter delivery times, metals producers need to have a manufacturing process…

Found in Robotics News & Content, with a score of 27.01

…has nearly 500 employees worldwide. It provides 3D cameras, machine vision software, and deep learning algorithms. It also offers motion-planning technology, programming models, and consulting and training services. The company said manufacturing and logistics customers can use its systems for mixed-order picking, palletizing and depalletizing, and machine tending. It claimed that its systems can attain picking speeds of 1,200 pieces per hour. In July, MechMind released its new Mech-Eye Nano, a small camera than can be mounted on robot arms for pick-and-place and other operations in manufacturing. It has worked with Siemens on using simulation to develop its products. Mech-Mind…

Found in Robotics News & Content, with a score of 22.81

…a wide range of applications, ranging from education to machine tending. The market for cobots has been expanding rapidly and is expected to grow by more than 50% in the next five years and ultimately represent nearly one-third of the entire industrial robot market. Ongoing automation trends are expected to strengthen interest across several applications such as: Light-duty mobile robotics – Cobots can be easier to integrate into a mobile manipulator that carries out operations near humans, such as stocking shelves in a warehouse. Assembly and disassembly – Cobots can handle a tedious staging task without complex safety systems while…

Found in Robotics News & Content, with a score of 9.77

…this mobile platform to perform repetitive tasks such as machine tending, quality assurance sampling, material replenishment, and packaging so they can focus on tasks requiring higher-level skills. Yaskawa MPX Yaskawa’s high-speed, six-axis MPX-series robots are designed to create smooth, consistent finishes for a variety of painting and dispensing applications. The MPX robots an be installed close to workpieces for efficient use of floorspace. Each model can be floor-, wall- or ceiling-mounted. These robots and the DX200-FM controller feature Factory Mutual (FM) approval for use in Class I, Division 1 hazardous environments. An intrinsically safe pendant is available as an option.…