Editors’ Picks

Found in Robotics News & Content, with a score of 15.82

…Mobile Robots Piece Picking Gets Faster With Robotic Perception Machine Tending and Welding With Robots More information about the sessions can be found at the event site. Unlike other robotics event, the first Robot Applications Conference will focus on robotics applications rather than individual technologies or market verticals. Speakers interested in participating in Robotics 24/7’s event can submit applications here. Please note that we are looking to speak to end users, analysts, and systems integrators. An attendee registration form will be up soon. Companies can learn more about sponsorship opportunities by contacting Tom Cooney at [email protected]. About Peerless Media Founded…

Found in Robotics News & Content, with a score of 15.76

…of inserting micro components, transferring delicate objects, or even machine-tending applications,” the company said. It will be available in the second quarter of 2023, according to the company. The Grav gripper will be compatible with cobots developed by other vendors. Source: Flexiv Flexiv at ATX West 2023 Flexiv will be attending ATX West 2023 this week and plans to showcase several of its automated systems. The automation and design trade show will be held in Anaheim, Calif., from Feb. 7 to 9 at the Anaheim Convention Center. Flexiv will be at Booth 4328. “It's great to be back at ATX…

Found in Robotics News & Content, with a score of 15.71

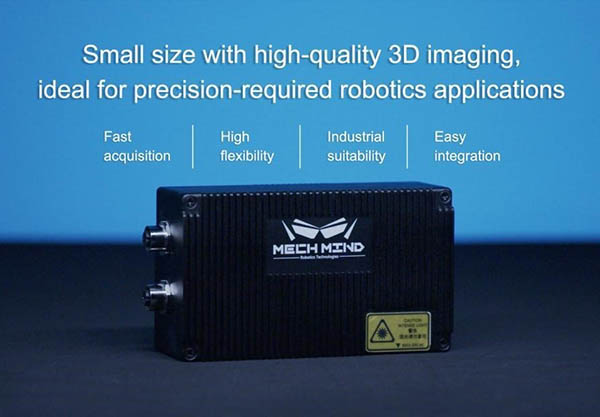

…solutions for palletizing and depalletizing, bin picking, order sorting, machine tending, and assembly/gluing/locating in logistics and manufacturing. It raised Series C financing in May, bringing its total funding to more than $100 million (U.S.). Mech-Eye Nano promises precision The palm-sized Mech-Eye Nano uses fast structured light to generate complete, detailed, and accurate point clouds with native and perfectly aligned color, said Mech-Mind. It can perceive a wide variety of objects, including tiny, shiny, reflective, and colored ones, with depth accuracy optimized to 0.05 mm at 0.3-0.4 m, according to the company. In pick-and-place robotics, Mech-Eye Nano enables demanding applications, including…

Found in Robotics News & Content, with a score of 15.67

…across the industry.” At launch, D:PLOY supports palletizing, CNC machine tending, packaging, and transferring (pick-and-place) applications. OnRobot said in the future it will add more capabilities to the platform. “D:PLOY automatically discovers most of the installed hardware, and generates the robot motion based on the obstacles and cell boundaries defined in the workspace,” the company said. “The program logic, signals exchange, event handling, and robot movement are automatically created for the entire application based on a few inputs such as workpiece attributes and pick position.” D:PLOY can be accessed on mobile, tablet, and desktop. Source: OnRobot Platform to make robotic…

Found in Robotics News & Content, with a score of 15.47

…experts will help manufacturers prototype solutions and demonstrate proofs-of-concept. The Hub will explore solutions in many manufacturing areas, including machine tending, assembly/disassembly, inspection, to name a few. Qualifications This service is available only to small and medium-sized manufacturers in the Southwestern Pennsylvania region, limited to the following 11 counties: Allegheny Armstrong Beaver Butler Cambria Fayette Greene Indiana Lawrence Washington Westmoreland Manufacturers must fit into the small and medium-sized range, defined as having 500 or fewer employees and less than $100M in annual revenue.

Found in Robotics News & Content, with a score of 15.27

…challenges that impede reshoring, taking on tasks such as machine tending, palletizing, and assembly. Source: OMRON Manufacturers turn to robotics To address this issue, many manufacturers are turning to robotics and other forms of automation with an eye toward making reshoring economically feasible. “With no end in sight to labor shortages, the use of robots is the answer for companies looking to reshore their production,” asserted Jerry Perez, manager of the Americas executive sales team at FANUC. A recent ABB Robotics survey bears this out, drawing a direct line from increased deployment of automation and robotics to greater efficiency and…

Found in Robotics News & Content, with a score of 15.19

…allow facilities to operate more efficiently. Automaker relies on human-machine collaboration Stellantis, an auto manufacturer that was formed after the merger of Fiat Chrysler Automobiles and PSA Group, is taking advantage of 11 collaborative robots in one of its electric car factories in Italy. From applying waterproof liners on vehicle doors to the mounting of hoods, the robots have become a major part of the process. The cobots were created by Odense, Denmark-based Universal Robots A/S, the market leader in the space with a 44% to 47% market share. Stellantis has been using Universal Robots’ cobots in Italy since 2017,…

Found in Robotics News & Content, with a score of 14.96

…automation Mobile robots and palletizing Piece picking and perception Machine tending and welding with collaborative robots RAC ’22 included presenters from integrators and end users such as Körber Supply Chain, GXO Logistics, and Toyota North America. Attendees included leading global companies including Ahold Delhaize, Amazon, Cargill, Carrier, Fuji, Garmin, General Mills, HomeGoods, Johnson & Johnson, the Mayo Clinic, and Starbucks. In addition, Aaron Prather, director of the Robotics & Autonomous Systems Program at ASTM International, delivered the keynote address on optimizing warehouse operations with robots and AI. He was previously former senior advisor for technology research and planning at FedEx.…

Found in Robotics News & Content, with a score of 14.67

…to program and apply to different tasks, such as machine tending or welding. The global market for cobots will grow from $590 million in 2020 to $1.9 billion by 2030 at a compound annual growth rate (CAGR) of 12.3%, predicted Research and Markets. Mordor Intelligence was similarly bullish, forecasting a CAGR of 18.37%, from $668.3 million in 2020 to $1.8 billion in 2026. Universal Robots claimed that it introduced “the world's first commercially viable” collaborative robot in 2008. Since then, the company has installed more than 50,000 cobots worldwide, representing a fast-growing niche in industrial automation. Universal Robots' product portfolio…

Found in Robotics News & Content, with a score of 14.56

…Columbus, Ohio-based company said that its offering will enable machine builders and software developers to create applications that scale across robot and automation brands. “For robotics to reach the scale we need as a society, we must make it easier for end users, and we must make it easier for developers,” stated Benjamin Gibbs, co-founder and CEO of READY Robotics. “As we’ve seen before with Windows and Android, software platforms can enable massive growth within an industry.” Founded in 2016, READY Robotics claimed that Forge/OS is the “first enterprise-grade operating system” for controlling hundreds of models of industrial and collaborative…

Found in Robotics News & Content, with a score of 14.23

…well as hardware options spanning from external axis and machine vision systems to fieldbuses. “The OmniCore difference is its ability to manage motion, sensors, and application equipment in a single holistic unified system,” said Marc Segura, ABB Robotics division president. “OmniCore opens the door to the entire ABB Robotics portfolio of hardware and software, in any combination under a single control platform, offering endless possibilities and more avenues for value creation. OmniCore operation design and optimization is enabled by software features including ABB’s Absolute Accuracy, PickMaster Twin, and RobotStudio. Source: ABB “For example, OmniCore enables automotive manufacturers to increase production…

Found in Robotics News & Content, with a score of 14.04

…of production by creating new synergies between humans and machines. By playing to the strengths of people and automation, multiple industries can improve productivity and product quality while reducing operating costs. Equipped with sensors for safe collaboration and accurate manipulation, ways of learning new tasks without programming expertise, and a variety of end-of-arm tooling, cobots can bring flexibility to shops of all sizes. Cobots promise to boost productivity Collaborative robots can perform the dull, dirty, and dangerous tasks once performed by humans. “This provides a double benefit,” said Joe Campbell, senior manager of applications development at cobot leader Universal Robots…