Editors’ Picks

Found in Robotics News & Content, with a score of 1.93

The NVIDIA Isaac robotics platform is tapping into the latest generative AI and advanced simulation technologies to accelerate AI-enabled robotics. At GTC 2024, NVIDIA announced Isaac Manipulator and Isaac Perceptor - a collection of foundation models, robotics tools and GPU-accelerated libraries. During Monday’s keynote, NVIDIA founder and CEO Jensen Huang demonstrated Project GR00T, a general-purpose foundation model for humanoid robot learning. Project GR00T uses various new tools from the NVIDIA Isaac robotics platform to create AI for humanoid robots. “Building foundation models for general humanoid robots is one of the most exciting problems to solve in AI today,” Huang said.…

Found in Robotics News & Content, with a score of 1.93

Industrial robot manufacturer ABB recently launched its latest modular large robots at Automate 2024 in booth 2239. The trade show is being held May 6-9 at the McCormick Place Convention Center in Chicago, Illinois. Attendance is free. A3 said this year’s show is the biggest yet, featuring more than 365,000 square feet of exhibit space, over 800 exhibitors, and an expected 30,000 registrants, with learning and networking opportunities. Attendees will be able to see the latest in robotics, machine vision, artificial intelligence (AI), and motion control. ABB Robotics is continuing the expansion of its modular large robot portfolio with the…

Found in Robotics News & Content, with a score of 1.88

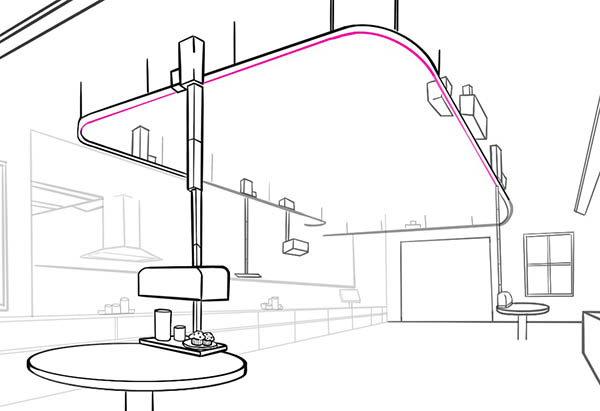

As with other industries, the COVID-19 pandemic has accelerated demand for automation in the restaurant industry. However, small and midsize businesses, or SMBs, have tight profit margins and are understandably reluctant to invest in new, complex technologies even as they struggle with turnover and labor shortages, according to Haitham Al-Beik, CEO of Wings. Littleton, Mass.-based Letsbutterfly Inc., which does business as Wings, is developing proprietary systems in its HiveRobotics Lab for “autonomous sustainable retail” (ASR). Al-Beik has spoken with several restaurant franchises about the challenges they face and what they want from robotics suppliers. He shared his findings with Robotics…

Found in Robotics News & Content, with a score of 1.85

Matt Yearling, CEO of PINC at ProMat Companies delivering products to customers are already dealing with workforce labor shortages and growing demand due to e-commerce, but shrinking warehouse vacancies and an overabundance of stock, due to fears of China tariffs, have created an inventory mess. At this year’s ProMat 2019 conference in Chicago, Matt Yearling, CEO of PINC, will present “Automating Your Inventory Management With Drones So It’s 100 Times Faster,” at 3 p.m. on Tuesday, April 9, 2019. The session is part of the CRO Summit at ProMat, produced by RoboBusiness and Robotics Business Review. The Chief Robotics Officer…

Found in Robotics News & Content, with a score of 1.82

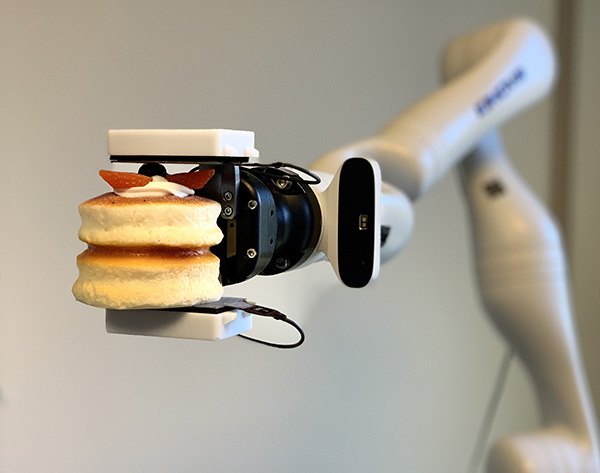

Amid rapid advances and adoption of robotic technology in materials handling, it can be hard to keep up with all the tipping points. Grippers, vision systems, navigation solutions and software are combining to make once fantastical robotic applications all but inevitable. But, even as they offer solutions to age-old challenges, concepts like robotic piece picking are also bound to present sizable tests. When it comes to piece picking, humans have the advantage of highly dexterous manipulation, versatile product identification and intuitive decision-making. Robots offer consistency and predictability, but they will need greater speed and flexibility to keep up with the…

Found in Robotics News & Content, with a score of 1.81

This top 10 list, taken from Modern Materials Handling’s 23rd-annual Top 20 Systems Suppliers list illustrates an industry at the top of its game, clearing previous records with ease. When we revisit the list next year, the impacts of the Covid-19 pandemic will likely be evident. However, since the crisis has made the supply chain’s critical importance abundantly clear, these companies have every chance to continue to perform well. The art and science of managing disruption have driven the last decade of innovation, and the industry must now lean into the biggest disruption in generations. Before Covid-19, the materials handling…

Found in Robotics News & Content, with a score of 1.81

Although industrial automation has been used in food processing for decades, produce handling has been difficult for robots to do. Not only are fruits and vegetables variable in size and shape, but they must also be handled delicately to avoid bruising. Scientists have recently made progress in developing tactile sensors to enable robots to approach or surpass human-level motor skills and meet growing industry needs. Researchers at Mitsubishi Electric Research Laboratories (MERL) have been working with the Department of Brain and Cognitive Sciences at the Massachusetts Institute of Technology on a prototype collaborative robot with tactile sensor technology. The ability…

Found in Robotics News & Content, with a score of 1.78

One of the biggest selling points for mobile robots is that they are not fixed infrastructure like conveyor belts and can thus change routes depending on seasonal volume, shifting workflows, or new products. In addition, increasingly sophisticated software promises to pick the best robots, manual and autonomous forklifts, and human workers as agents for a particular task. But this is easier said than done. As much as 70% of North American warehouses and distribution centers have yet to add any automation, industry experts have told Robotics 24/7. Even businesses that have robotics experience can run into problems growing their fleets…

Found in Robotics News & Content, with a score of 1.77

BOSTON—At MassRobotics’ fifth annual Robot Block Party this weekend, the public had an opportunity to see and touch many of the robots developed and built in Massachusetts. The event was part of RoboBoston, which included a career fair last Friday. Approximately 5,000 people attended the Robot Block Party, according to Joyce Sidopoulos, co-founder and chief of operations at MassRobotics. Over 760 people registered for the Robotics and AI Technical Career Fair—even more than expected, she added. The Robot Block Party drew families from Boston’s growing Seaport District and beyond. “We’re just grateful to all our partners, and we hope the…

Found in Robotics News & Content, with a score of 1.72

DETROIT—With more than 750 exhibitors, over 125 conference sessions, and about 25,000 registered attendees, the Automate 2023 trade show this week was the latest demonstration of the growing interest in industrial automation and robotics, despite economic concerns. Conference sessions about getting started with adopting automation were particularly well-attended, and we saw several Fortune 500 companies' delegations carefully evaluating systems and questioning booth personnel. Attendance was strongest on Tuesday, according to several exhibitors. The Association for Advancing Automation (A3) announced that Automate, which used to be co-located with ProMat in Chicago and held every other year, is becoming an annual event.…

Found in Robotics News & Content, with a score of 1.71

A new IDTechEx Research report explores mobile robotics in materials handling and logistics, which is predicted to become a $75 billion market by 2027 before doubling by 2038. These are among the findings of Mobile Robots & Drones in Material Handling & Logistics 2017-2037, which includes automated guided vehicles and carts (AGVs and AGCs); autonomous mobile vehicles and carts/units; mobile picking robots; last mile delivery ground robots (droids) and drones; and autonomous trucks and light delivery vans (level 4 and level 5 automation). Khasha Ghaffarzadeh, research director at IDTechEx and the report’s author, said the figures “mask turbulent transformative change…

Found in Robotics News & Content, with a score of 1.70

The “2021 MHI Annual Industry Report,” conducted with Deloitte, opens with a quote from John Paxton, CEO of the Materials Handling Institute. “Supply chain resilience has never been more important,” he wrote. “Companies that made investments in digital technologies prior to the pandemic were more prepared and able to adapt, survive and even thrive during this disruption. They will also be ready when the next crisis inevitably hits.” Historically, when it came to the adoption of automation and emerging technologies, warehousing and distribution took a wait-and-see approach. For example, the automotive industry has been using robotics since General Motors installed…