Editors’ Picks

Found in Robotics News & Content, with a score of 17.54

…exhibits comprise the latest technologies and innovations in robotics, machine vision, motion control, artificial intelligence (AI) and related automation technologies. Welding, assembly and machine tending robots, mobile robots and human-robot collaborative technologies with intuitive user interfaces and software advances, machine learning and advanced computer vision technologies are just a few of the solutions that will be on display. Many companies will be introducing new technologies never before seen in North America. More than 120 Automate conference sessions explore how automation secures a company’s success in a technologically fast-paced world where AI, IIoT, smart manufacturing, cobots, machine vision and other innovations…

Found in Robotics News & Content, with a score of 17.35

…(Bill) Twickler, vice president of solutions at GXO Logistics Machine Tending and Welding With Cobots: Josh Pawley, founding partner at Vectis Automation, and Brian Havey, director of sales at VersaBuilt Robotics Piece Picking Gets Faster With Robotic Perception: Sandeep Sakharkar, CIO of GXO Logistics Other sessions include “Palletizing and the Next Frontiers for Mobile Robots.” More speakers will be announced soon, and qualified experts can still apply to participate. Register now for the Robotics Applications Conference The Robotics Applications Conference is free, and registration is now open for all sessions. Visit Robotics 24/7 for the latest news about the commercial…

Found in Robotics News & Content, with a score of 17.24

…assembling, processing, or prototyping large scale components, material handling, machine/conveyor tending, flexible manufacturing, and peg-in-hole insertion-type assembly. “Static/indexed performance encompasses situations in which the manipulator and A-UGV of a mobile manipulator shall not move simultaneously while physically connected as a single unit,” said ASTM International. It recently announced a standard, F3588-22, supporting UGVs. Users to verify mobile manipulator performance ASTM International member Omar Aboul-Enein noted that the proposed standard (WK83858) will be used by manufacturers, suppliers, integrators, and end users to verify the performance characteristics of a mobile manipulator. “Once approved, end users might use the practice to determine if…

Found in Robotics News & Content, with a score of 17.23

…build new relationships with customers looking to upgrade their machine tending, material handling, palletizing, surface treatment, and precision handling capabilities. Infinity Robotics integrates into multiple industries With more than 10 years of experience in the distribution and manufacturing of automated control systems, Infinity Robotics said it provides innovative and customizable manufacturing systems to its customers in and around Minnesota. The Savage, Minn.-based company said that it specializes in the sale of robots and automation equipment and that it can integrate cobots, computer vision systems, and customized automation into any industry. “We are excited to be the Midwest Integrator and Distributor…

Found in Robotics News & Content, with a score of 17.02

…24/7. MIRAI designed to hasten flexible robot use Certain machine tending, assembly, or test applications have been difficult to automate because of variances in position, shape, surface properties, or lighting conditions. Previously, human labor was required for production tasks involving different placement of workpieces, gripping objects with unstable shapes, or picking reflective or transparent materials. MIRAI uses artificial intelligence and machine vision to enable robots to react to variances in tasks in real time by learning from humans, said Micropsi. With the company's distribution and integration network, the control system is designed to enable users to deploy automation without in-house…

Found in Robotics News & Content, with a score of 16.85

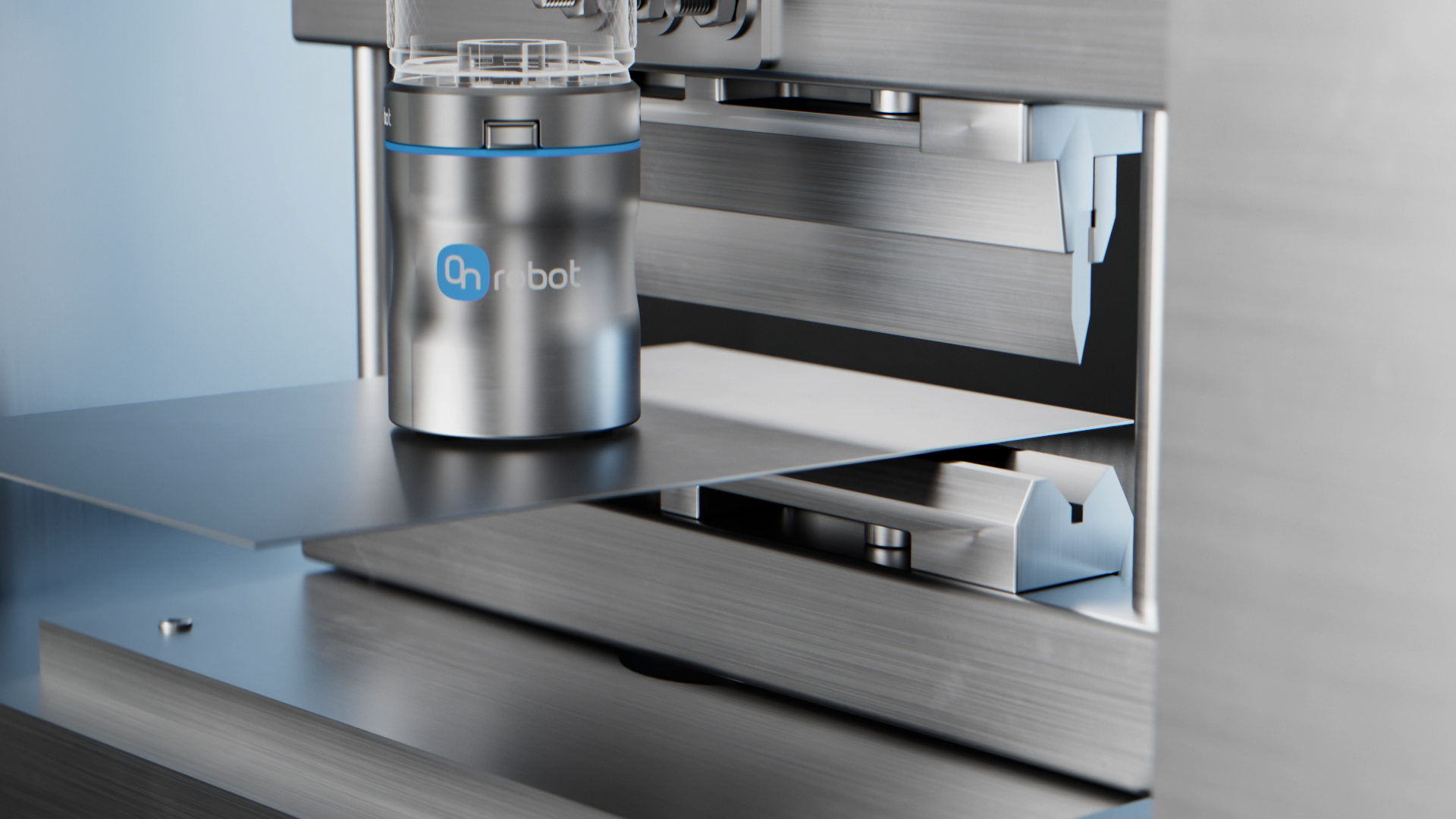

…the MG10 is designed for materials handling, assembly, and machine-tending applications in manufacturing, automotive, and aerospace applications. “Standard magnetic grippers only provide simple on/off functionality,” stated OnRobot. “To adjust the force applied, users have to add rubber ‘feet’ to create space between the magnet and the part. This is a tedious and imprecise process that doesn’t always guarantee perfect results, especially on applications that involve handling thin metal sheets and small metal parts where magnetic grippers often accidentally end up picking more than one sheet or part as the force cannot be adjusted.” The MG10's built-in sensing capabilities ensure smooth…

Found in Robotics News & Content, with a score of 16.74

…remain challenging for piece-picking operations. Advances in computer vision, machine learning, and end-of-arm tooling are now enabling robots to pick at human and even superhuman rates. One company focusing on successful automation of pick-and-place workflows is Material Handling Systems Inc. (MHS). The Mt. Washington, Ky.-based company spun out MHS Robotics from its research and development unit last year. Kristiyan Georgiev, R&D manager for computer vision and software engineering at MHS, spoke with Robotics 24/7 about improvements in robotic picking applications. How long have you been at MHS, and how does your prior experience help you manage these technologies? Georgiev: I…

Found in Robotics News & Content, with a score of 16.54

…for many supply chain and manufacturing applications. RIOS Intelligent Machines Inc. said it has developed haptic intelligence for manipulation tasks that were previously difficult to automate, such as packing, machine tending, and autobagging. Smarter and more dexterous robots sound great, but how can the majority of warehouses, which are not yet automated, get started with them? Robotics 24/7 chatted with Dr. Bernard Casse, founder and CEO of RIOS, about rethinking business models as capital becomes scarce and how the robotics-as-a-service (RaaS) model can enable robot adoption. Do your due diligence Even before Silicon Valley Bank's problems, robotics suppliers and users…

Found in Robotics News & Content, with a score of 16.47

…for an AMR that’s sitting in front of a machine while the manipulator is loading or tending this machine?” Ryder AMR can relocate Reacher arms autonomously Rethink Robotics lineup of cobot arms and AMRs can be combined to form a Riser mobile manipulation platform. Because the robots are designed to be combined, Ryder AMRs can also be used to relocate Reacher arms throughout a facility. “It really comes to the benefit of the workflow where we drop the cobot, and the AMR can take off and take care of other jobs while the robot arm is charging plus taking care…

Found in Robotics News & Content, with a score of 16.42

…staff works out of a 95,000-sq.-ft. steel fabrication and machine shop. “As manufacturing is coming back to the States, we're getting more orders than we can handle,” said Helfrich, a manufacturing engineer at the company. “We used to build two to three [systems] a month. Now, they want 100 and maybe even 150 a year, so it's quite an increase in production.” The company takes advantage of some semi-automated processes for CNC machining and welding, but it's hoping to invest in a robotic arm or two to help with welding and cutting. Helfrich Brothers Boiler Works, like many small and…

Found in Robotics News & Content, with a score of 16.20

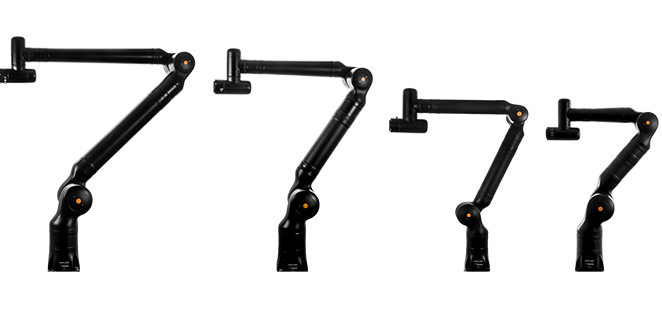

…and integrators quickly and cost-efficiently automate complex tasks in machine tending, material handling, general automation, and related applications. The KR series provides a reach of about 3 to 6 ft. (850 to 1,800 mm) and payloads around 11 to 40 lb. (5 to 18 kg) to automate a variety of physically demanding and/or repetitive tasks. In addition, each joint offers speed of 225 degrees per second to keep up with pick-and-place tasks, quality inspection, and palletizing. Kassow said its seventh axis and flexibile software enable continuous dispensing, welding, and material removal regardless of access angle, without the need to reorient…

Found in Robotics News & Content, with a score of 15.99

…wide range of production tasks including material handling and machine tending and assembly, as well as specific operations in electric vehicle (EV) manufacturing such as battery module picking and placing, high precision assembly, and parts handling, the company said. The IRB 5710 and IRB 5720 are available in range of variants, the company said, with payload options ranging from 70 to 180 kg (154.3 to 396.8 lb.). Reaches range from 2.3 to 3 m (7.5 to 9.8 ft.). Addressing the EV market Joerg Reger, managing director of ABB's automotive business line, said the new robots help accelerate the company’s “expansion…