Editors’ Picks

Found in Robotics News & Content, with a score of 11.85

…easy connection of a FANUC CRX cobot and a machine tool. QSSR simplifies the automation of machine tool load/unload applications using the CNC controller’s easy guidance functionality for quick connectivity, start-up and operation. FANUC CR-35iB will assemble a bike At the show, the CR-35iB collaborative robot will help an operator assemble a bicycle. The operator will program various assembly positions with the easy-to-use tablet TP featuring a “drag and drop” user interface. The demonstration underscores the cobot’s ability to make the assembly process quicker while eliminating ergonomic stress, the company said. The CR-35iB collaborative robot has a payload of 35kg…

Found in Robotics News & Content, with a score of 16.20

…and integrators quickly and cost-efficiently automate complex tasks in machine tending, material handling, general automation, and related applications. The KR series provides a reach of about 3 to 6 ft. (850 to 1,800 mm) and payloads around 11 to 40 lb. (5 to 18 kg) to automate a variety of physically demanding and/or repetitive tasks. In addition, each joint offers speed of 225 degrees per second to keep up with pick-and-place tasks, quality inspection, and palletizing. Kassow said its seventh axis and flexibile software enable continuous dispensing, welding, and material removal regardless of access angle, without the need to reorient…

Found in Robotics News & Content, with a score of 12.86

…Georgian. “We have seen firsthand how Vention delivers integrated software and hardware innovations, such as palletizing, conveyor, and robot tending applications, that foundationally transform their customers' manufacturing operations.” Toronto-based Georgian invests in high-growth companies, bringing together software entrepreneurs, machine learning experts, experienced operators, and investment professionals.

Found in Robotics News & Content, with a score of 31.85

…May 1. “The industrial sector is looking to automate machine tending but lacks the people to develop, design, and implement the automation solutions.” “We manufacture complete robot cells that have a delivery time of 14 days and can then be installed and safety approved in just 24 hours,” he added. “When customers receive a delivery from us, it arrives in a large wooden crate and is then up and running and generating value the very next day.” Lachenmeier, who is a third-generation entrepreneur, founded EasyRobotics in 2014. Kjempff joined the company in 2018 and took responsibility for ensuring that EasyRobotics…

Found in Robotics News & Content, with a score of 13.49

…specializations among U.S. robot suppliers were handling and picking (69% of suppliers), assembly (45%), inspection and quality assurance (32%), machine tending (29%), and welding (27%). Many of the companies and technologies mentioned in the report will be on full display at the Automate Show in Detroit from June 6 to 9, 2022. Registration is free and available now.

Found in Robotics News & Content, with a score of 11.06

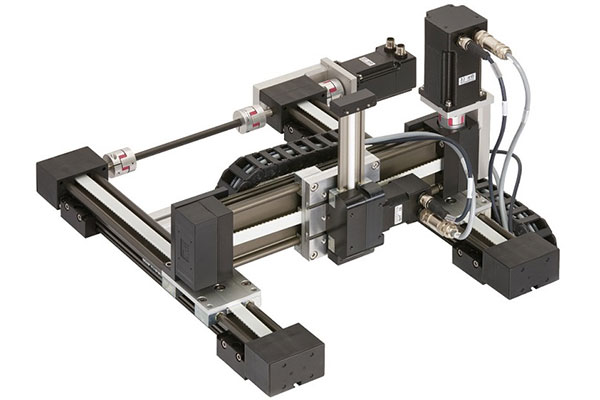

…are used for arc welding, material handling, assembly, packaging, machine tending and palletizing. They have a predesigned reach and accuracy ratings that make it easier to establish their repeatability of movement (Richard Vaughn). However, unlike Cartesian and gantry robots, you’re locked into those design features once you buy it. Robotic arms could also cost more because of expensive features like proprietary controllers. 4. SCARA SCARA stands for selective compliance assembly robot arm or selective compliance articulated robot arm. It has three axes (X, Y and Z) for rotating and lateral movements and is ideal for vertical assembly, bio-med and palletizing.…

Found in Robotics White Papers & Archives, with a score of 44.95

…and precision are also changing how tasks such as machine tending, packaging, and welding are done. However, many small and midsize enterprises (SMEs) are reluctant to invest in systems for high-mix, low-volume applications. Integrators must evaluate the latest sensors, software, and end effectors for different use cases. In addition, researchers, integrators, and end users must consider the level of interaction with human co-workers, environmental conditions, and the safety of different payloads. In this Special Focus Issue, we consider how cobots have become a fast-growing segment of automation and how suppliers are turning their focus to specific applications. This free download…

Found in Robotics News & Content, with a score of 15.99

…wide range of production tasks including material handling and machine tending and assembly, as well as specific operations in electric vehicle (EV) manufacturing such as battery module picking and placing, high precision assembly, and parts handling, the company said. The IRB 5710 and IRB 5720 are available in range of variants, the company said, with payload options ranging from 70 to 180 kg (154.3 to 396.8 lb.). Reaches range from 2.3 to 3 m (7.5 to 9.8 ft.). Addressing the EV market Joerg Reger, managing director of ABB's automotive business line, said the new robots help accelerate the company’s “expansion…

Found in Robotics News & Content, with a score of 30.32

…America. The collaborative robot is strong enough to perform machine tending with heavy metal and plastic parts and precise enough to carry out pick-and-place tasks at high payloads, said the company. “The KR1018 is a very strong, compact cobot with a weight of only 34 kg [74.9 lb.], ideal for performing various jobs at industrial companies,” said Dieter Pletscher, head of global sales at Kassow Robots. “SMEs [small and midsize enterprises] without their own robotics specialists can achieve complex automation and programming cost-effectively and independently with the KR1018.” Kastrup, Denmark-based Kassow Robots designs and manufacturers seven-axis lightweight robots for industrial…

Found in Robotics News & Content, with a score of 21.59

…to use. Tasks or applications growing in popularity include machine tending and welding. Coupled with the labor shortage and an aging workforce, more and more businesses are starting to see the value of industrial automation. Top shops around the world Many of the top industrial automation providers are based in Asia or Europe, rather than in North America. Some examples include Zurich, Switzerland-based ABB Group and Kitakyushu, Japan-based Yaskawa. They are big companies with employees ranging in the thousands, and each has U.S. offices. The biggest robotics vendors have billions of dollars in annual revenue. As these companies get bigger,…

Found in Robotics News & Content, with a score of 15.19

…allow facilities to operate more efficiently. Automaker relies on human-machine collaboration Stellantis, an auto manufacturer that was formed after the merger of Fiat Chrysler Automobiles and PSA Group, is taking advantage of 11 collaborative robots in one of its electric car factories in Italy. From applying waterproof liners on vehicle doors to the mounting of hoods, the robots have become a major part of the process. The cobots were created by Odense, Denmark-based Universal Robots A/S, the market leader in the space with a 44% to 47% market share. Stellantis has been using Universal Robots’ cobots in Italy since 2017,…

Found in Robotics News & Content, with a score of 14.04

…of production by creating new synergies between humans and machines. By playing to the strengths of people and automation, multiple industries can improve productivity and product quality while reducing operating costs. Equipped with sensors for safe collaboration and accurate manipulation, ways of learning new tasks without programming expertise, and a variety of end-of-arm tooling, cobots can bring flexibility to shops of all sizes. Cobots promise to boost productivity Collaborative robots can perform the dull, dirty, and dangerous tasks once performed by humans. “This provides a double benefit,” said Joe Campbell, senior manager of applications development at cobot leader Universal Robots…