Editors’ Picks

Found in Robotics News & Content, with a score of 2.30

…said Ronny Bernstein, CEO of BMG. “Often, the extended delivery time is linked to the customer’s ordering process, as the administrative procedures frequently take too long, when BMF ships the spare parts on the same date.” “Via Digital Source, the component can be printed on-site the moment a failure or wear is detected,” he said. “Above all is uptime for our customers. The machine must run, and the customer must be able to continue producing.” “Now, the majority of advanced composite parts are printed directly at the customer location, which not only brings down the time it takes to receive…

Found in Robotics White Papers & Archives, with a score of 23.74

Picking and packing deliveries takes an average of four to eight hours of fulfillment operations. Best-in-class retailers are doing it in just two hours. The difference between those time frames is staggering. Even more so when you consider that almost half of your consumers will shop elsewhere when delivery times are too long. As a critical factor in the speed equation, picking improvements can help retailers leap from average to top performers. By combining automation and orchestration, companies have transformed their current picking practices into efficient processes that enable higher speed and accuracy. The gains are also prominent in improving…

Found in Robotics News & Content, with a score of 3.64

…team up with Locus Robotics “underscores its commitment to optimizing operational efficiency, reducing order processing times, and ensuring timely delivery to customers worldwide.” Not only does the deployment of 16 Locus AMRs position Solo to optimize its order-fulfillment operations today, but it also enables it to easily scale to meet future demand, said the partners. “The partnership reflects Solo Brands' dedication to innovation and continuous improvement,” they stated.

Found in Robotics News & Content, with a score of 22.17

…Pickup. The company said it enables a fully autonomous delivery process—from order placement through pick-up and delivery to customers’ yards. Flytrex claimed that its new capability can cut delivery times to about five minutes from the time orders are ready, creating growth opportunities for QSRs and family-owned restaurants. “What’s so unique about this innovation is its real potential to move the needle, with more and more businesses getting on board with an undeniably seamless and cost-effective process,” stated Yariv Bash, co-founder and CEO of Flytrex. “This upgrade is a huge step forward in achieving our vision to provide drone delivery…

Found in Robotics News & Content, with a score of 3.17

…operational design. Shell and Nauticus said their joint development “could lead to a step change in technology and service delivery for the offshore sector.”

Found in Robotics White Papers & Archives, with a score of 10.59

…agility and responsiveness to increasing customer expectations for faster deliveries and changing business and supply chain conditions. Two types of AMRs are most frequently deployed in distribution or fulfillment operations: Goods-to-Person and Person-to-Goods. Although they may seem similar at first, the productivity and efficiency gains are very different. Goods-to-Person AMRs bring items to associates or robotic picking arms for order fulfillment, eliminating walk and search time. Conversely, Person-to-Goods AMRs support associates as they travel through the aisles, picking needed items like a shopper in the grocery store. This whitepaper compares the two styles to help operations determine which type works…

Found in Robotics News & Content, with a score of 2.24

…to a predefined area in a facility with multiple delivery locations. It can place a pallet in the first open spot based on sequential order – even if the spots are not in one continuous row or adjacent to one another, the company explained. The Big Joe Pallet Mover includes lidar, an intuitive user interface, and a camera system to transport and drop pallets to locations once the operator selects a mission. “This collaborative approach uses self-driving technology as a productivity force multiplier by allowing workers to focus on higher-value tasks or direct multiple independent workflows concurrently,” said Big Joe.…

Found in Robotics News & Content, with a score of 5.80

…fulfill orders of single-picked items for same-day or next-day delivery. This design makes the technology suitable for distributed warehouse networks in urban areas, asserted Fabric. By putting goods closer to population centers, retailers can cut shipping costs and expedite delivery times, it noted. Final preparations are under way, and Maersk said it expects the site to be fully operational this fall in support of an online B2C retailer. Fabric relies on experience with retailers “With our proven track record of operating our state-of-the-art facilities for the past five years, we have honed our capabilities to make each piece of the…

Found in Robotics News & Content, with a score of 1.80

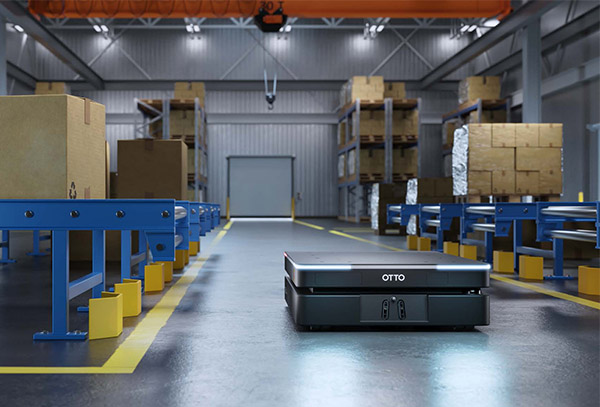

…including inbound to storage, finished goods takeaway, and lineside delivery, thanks to its ability to move payloads on pallets, racks, and bins. For brownfield facilities that are already tight and crowded, OTTO 1200 still maximizes productivity. It can even help those manufacturers convert one way aisles into two-way aisles. OTTO 1200 would also be a great fit where human and robot interaction is high. It is designed to deliver performance and safety, so manufacturers can expect to meet their throughput targets while ensuring that their people are safe. What were some of the technical challenges of developing this robot? How…

Found in Robotics News & Content, with a score of 3.03

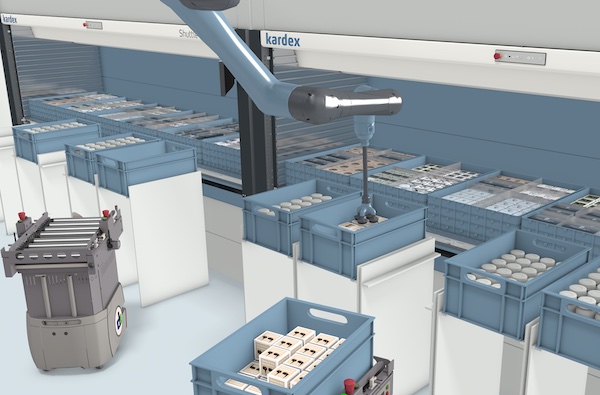

…a great reputation for quality products and on-time project delivery.” “Just like the AutoStore Control Software (ACS), tSort will directly integrate into the Kardex FullfillX WES [warehouse execution system], which will ensure our clients get a streamlined software solution for their overall system,” he noted. “At Kardex Solutions, we're focused on delivering AutoStore solutions that maximize value for our clients through straightforward designs and solutions. Adding tSort to our portfolio allows our clients to more efficiently fulfill orders while reducing their operating costs.” Kardex said it is a leading provider of ASRS and material handling systems for intralogistics. The Zurich-based…

Found in Robotics News & Content, with a score of 2.93

…are hitting the road in the forms of robotaxis, delivery robots, and self-driving trucks. Stack AV Co. yesterday announced the launch of its autonomous trucking business, which it said uses technology to improve efficiency and safety while tackling supply chain challenges for its partners and consumers. “With customers at its core, Stack AV is focused on revolutionizing the way businesses transport goods, designing solutions to alleviate long-standing issues that have plagued the trucking industry, including driver shortages, lagging efficiency in uptime per vehicle, overarching safety concerns, high operating costs, and elevated emission levels,” stated the company. Pittsburgh-based Stack AV said…

Found in Robotics News & Content, with a score of 2.79

…new vision of how effective and efficient their assembly, delivery and picking processes can be,” said Parsh Patel, CEO of ResGreen. “We are confident that our SimuPath program will set new benchmarks in cost-effectiveness and place our clients at the forefront of their industries.” SimuPath offers two modes ResGreen said SimuPath will be available in two simulation modes: Mode A – Fixed Structure: This mode presents a static, digital replica of a warehouse or plant, with elements such as racks, storage containers, and machinery firmly set in place. The AI algorithms then process the facility’s current arrangement and devise the…