Tompkins Robotics and Kardex Solutions LLC this week announced a strategic partnership to jointly offer systems they said will help customers improve service levels and be more competitive.

“Our partnership with Kardex will help customers drive labor savings, greater automation of fulfillment processes, and create value beyond what either firm can deliver individually,” stated Mike Futch, president and CEO of Tompkins Robotics. “The innovative solutions delivered by our partnership allow efficiencies and cost savings for our customers.”

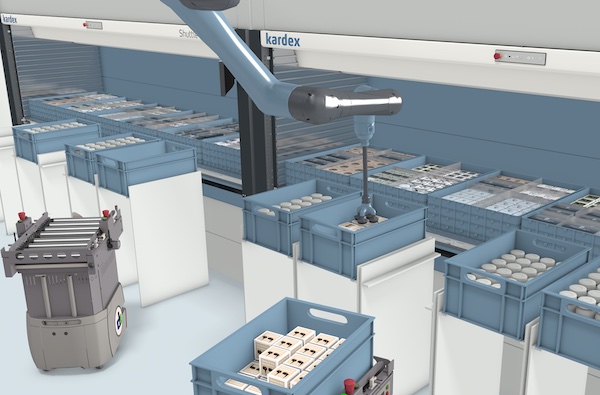

Kardex said the partnership will allow it to offer Tompkins Robotics' picking, sortation, and take-away automation. In addition, Kardex can provide its AutoStore automated storage and retrieval system (ASRS) with Tompkins' tSort sortation system for further efficiencies and a faster return on investment (ROI).

Kardex to integrate Tompkins, AutoStore systems

“We're excited to partner with Tompkins Robotics,” said Mitch Hayes, president of Kardex Solution. “In addition to being a leader in supply chain innovation, Tompkins has a great reputation for quality products and on-time project delivery.”

“Just like the AutoStore Control Software (ACS), tSort will directly integrate into the Kardex FullfillX WES [warehouse execution system], which will ensure our clients get a streamlined software solution for their overall system,” he noted. “At Kardex Solutions, we're focused on delivering AutoStore solutions that maximize value for our clients through straightforward designs and solutions. Adding tSort to our portfolio allows our clients to more efficiently fulfill orders while reducing their operating costs.”

Kardex said it is a leading provider of ASRS and material handling systems for intralogistics. The Zurich-based company's two divisions, Kardex Remstar and Kardex Mlog, serve as partners over the entire life cycle of a customer's product or solution.

From project analysis to realization and service, Kardex said it can help improve a customer’s performance and efficiency every step of the way. It has three production plants in Germany and one in North America to ensure high-quality products.

Kardex Group added that is investing in research and development, expanding its service organization, and new technology through acquisitions. Its partners include AutoStore, Rocket Solution, Robomotive, Intertex, and Sumobox. The company said that it has 2,000 employees across 30 countries and that it has installed more than 140,000 industry-specific systems worldwide.

tSort allows ASRS to reach more destinations

Futch claimed that Raleigh, N.C.-based Tompkins teaming up with Kardex Solutions on an AutoStore project can result in increased productivity.

“Working with Kardex Solutions to deploy the AutoStore and tSort solutions as an integrated whole will increase destinations available for each bin presentation by 20X in the system,” he said. “With tSort, the AutoStore can have any port reach any destination and allow the AutoStore system to have a large batch capability, making the combined system much more efficient.”

Tompkins Robotics said it has developed automation for distribution and fulfillment operations. The company said tSort and its subsequent innovations provide customers with flexibility and capacity throughout their supply chain processes.

Tompkins' upstream systems include its Pick Assist autonomous mobile robot (AMR), PickPal. Its downstream technology includes xChange, which the company described as “the only automated takeaway unit from a unit-sorter robot.”

tWES is Tompkins' is a warehouse execution system (WES) to link all these technologies. The company said its systems can maximize modularity, floorspace, flexibility, and speed of implementation, while its robotics-as-a-service (RaaS) financing option offers customers fast ROI.

Kardex Solutions and Tompkins Robotics will exhibit at adjacent booths, N-10129 and N-10130, at PACK EXPO from Sept. 11 through 13 in Las Vegas.

Editor's note: For more about PACK EXPO, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up