Editors’ Picks

Found in Robotics News & Content, with a score of 15.27

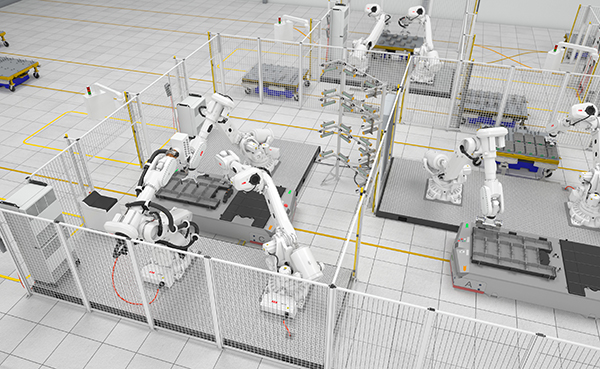

…of robots suitable for complex tasks such as spot welding, laser welding, screwdriving, and riveting, said ABB. This allows automotive manufacturers to achieve high-quality assembly, the Auburn Hills, Mich.-based company asserted. “Our new robot range meets the needs of the rapidly growing electric vehicle (EV) industry,” said Joerg Reger, managing director of the automotive business line at ABB Robotics. “As manufacturers ramp up production of EVs and batteries, they can choose from a wide range of ABB robots to ensure they have the right variant to handle batteries of varying sizes, from individual cells and modules to complete packages.” “They…

Found in Robotics News & Content, with a score of 15.07

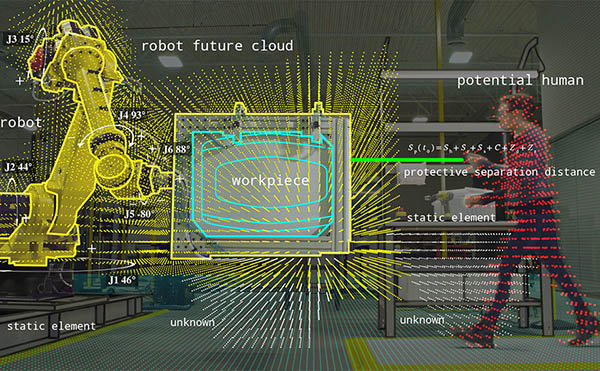

…Inc. has commercialized collaborative robots and AI for automated welding in pipe-fabrication shops. The startup has raised $3 million and is based in North Vancouver, British Columbia. It offers the Spool Welding Robot (SWR), the SWR+HyperFill integrated dual-torch system, the NovEye vision and image-processing system for fully automated welding, and NovSync for data analytics. Rokae Technology Co. in Beijing provides a cobot, a six-axis robot, and the Titanite control system, as well as custom support. Founded in 2015, the company has received $138 million and partnered with German firm Jaeger Engineering to expand in the growing European market. Veo Robotics…

Found in Robotics News & Content, with a score of 15.00

…overcome labor constraints.” CRX cobots demonstrated palletizing, kitting, and welding Attendees got a chance to experience FANUC’s range of CRX cobots and learn how to program them using hand-guided programming or the Tablet TP interface. A new CRX-25iA food-grade cobot demonstrated collaborative palletizing and depalletizing from an infeed conveyor to two pallets. Designed to operate safely in food processing facilities, the CRX-25iA’s white epoxy coating meets the USDA Incidental Food Contact Requirements. It has an IP67 washdown rating and uses NSF H1 food grade lubricant. The demonstration featured the new PalletTool 3, which enables operators to create and modify unit…

Found in Robotics News & Content, with a score of 14.47

…applications are vast, ranging from materials handling, quality inspection, welding, and even food preparation and serving. In 2020, the global collaborative robot market was sized at $668 million, according to Mordor Intelligence. It is expected to reach $1.8 billion by 2026, according to the research firm. Future Market Insights estimated that the market will reach about $1.7 billion by the end of 2022. And by 2029, it will have a valuation of $8.6 billion. There are still limitations on what cobots can do in terms of payload weight, speed, and range. But cobot manufacturers are continuing to release cobots aimed…

Found in Robotics News & Content, with a score of 14.43

…high-accuracy contact applications, such as machining and friction stir welding, the company said. Powered by OmniCore controllers, ABB said its new robots can achieve motion control with path accuracy down to 0.6 millimeters, or about 0.025 inches, even with multiple robots running at high speeds of up to 1600 millimeters per second, or about 63 inches per second, and moving payloads of up to 620 kilograms, or about 1,350 pounds. Customers can also benefit from an up to 25% reduction in cycle times compared to previous ABB robots. In the automotive industry, the all-new IRB 7710 with the latest OmniCore…

Found in Robotics News & Content, with a score of 14.41

…order and fleet management, and cloud-based traceability systems. Robot welding in Detroit At Automate, ABB plans to demonstrate a collaborative robot welding cell. The GoFa CRB 15000 is designed to work alongside people and to be easy to install and use for repetitive tasks. The cobot will perform live arc-welding demonstrations. Booth visitors will be able to use ABB’s customizable two-button Lead-Through Programming function to tack and weld small parts. By moving the robot in the desired weld path, visitors can create their own weld programs and watch GoFa replicate that path in live welds. Also equipped for welding, ABB…

Found in Robotics News & Content, with a score of 14.34

…applications including assembly, material handling, part transfer, palletizing, and welding. “The high-performance of the M-710i robot series has made it a great choice for a variety of applications over the years,” said Eric Potter, general manager, General Industries and Automotive Segments, at FANUC America. “The new model includes all of the best features of the long-standing series with several key enhancements that will expand its capabilities.” Additional features and benefits include: A long 2,606mm reach Water and dust proof design with fully enclosed arm and no exposed reducers The entire robot is IP67-rated for protection in harsh environments Easy to…

Found in Robotics News & Content, with a score of 14.17

…and lack of people, for example, skilled in arc welding,” Latokartano said. Twenty four percent of robotics companies in Finland specialize in welding automation, according to the market report. It also identified other industrial applications, including machining, assembly, quality control, and many others. New sectors ready for robotics Source: HowToRobot Despite the machinery industry’s strong influence on robotics in Finland, automation providers are also expanding to other areas, such as logistics, according to the report. 34% of suppliers specialize in logistics systems used in a wide range of industries. “There is growing potential for automating internal logistics across healthcare, manufacturing,…

Found in Robotics News & Content, with a score of 13.91

…in robotics trajectory computation and off-line programming of arc welding robots. This solution allows Alma to use the full ESPRIT additive DED cycles such as 3x, 4x and 5x, bringing the software to a new level of support for additive technology, the companies say. The solution also allows ESPRIT to support industrial robot brands including Yaskawa, ABB, Fanuc, Kuka and others. The result of this technology partnership is a complete workflow to provide end users with: dedicated additive toolpath planning and programming; robot programming, simulation, verification, collision detection and code generation; and subtractive finishing process planning, simulation, verification, collision detection…

Found in Robotics News & Content, with a score of 13.86

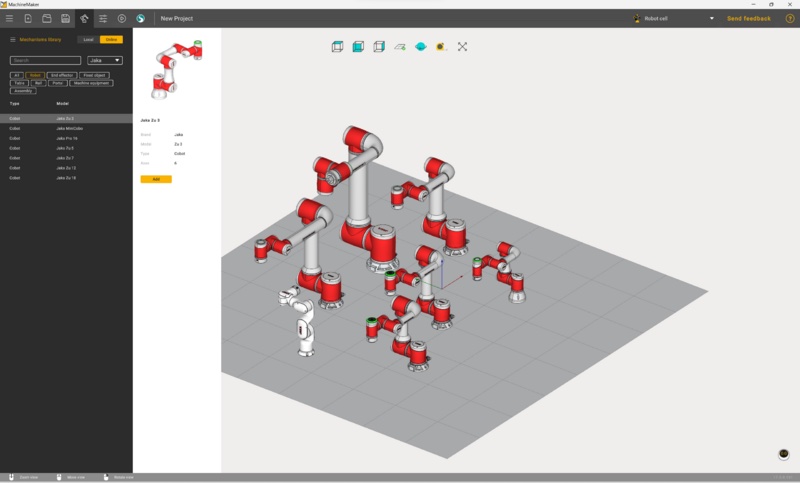

…±0.02 and ±0.03mm. They are versatile, used in assembly, welding, machine tending, inspection, testing, dispensing (painting, coating, gluing, bonding), and finishing applications (polishing, grinding). To program JAKA cobots with SprutCAM X Robot, users should download and install the requisite software. https://sprutcam.com/download/ A free 30-day fully functional license will be granted automatically. The next step involves opening MachineMaker, an application for creating digital twins of industrial robots in SprutCAM X Robot, and finding the appropriate cobot in the online Robot Library. The developers of SprutCAM X Robot have plans to support the full range of JAKA Robotics models. They are also…

Found in Robotics News & Content, with a score of 13.82

…industrial and collaborative robot makers are offering systems for welding and other industrial applications. Robotics 24/7 has already covered several welding robots, and here are other systems that captured attendee attention at Fabtech 2021: AGT Robotics LayoutMaster AGT Robotics' LayoutMaster is a full-color laser projection system designed to project all the information that an operator needs to accurately tack-weld connections on the beam or on other connections. The LayoutMaster projects complete and comprehensive information, including 3D contours, holes, holes center, welding information, part numbers and other details. Thus, an operator with limited training can align the connection with the projected…

Found in Robotics News & Content, with a score of 13.79

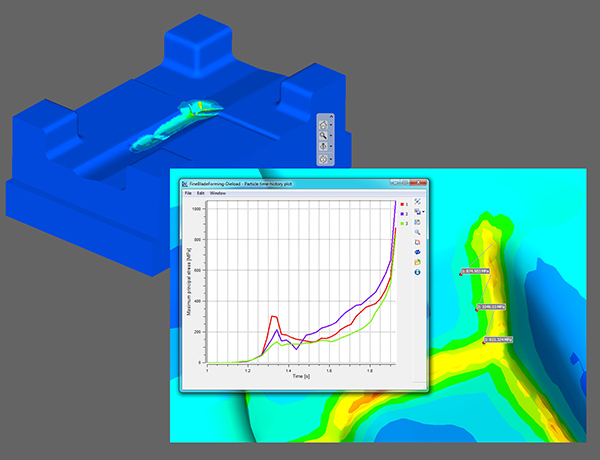

…16 offers one-click import of model data from Simufact Welding and Simufact Additive. For example, users can import two previously welded components from Simufact Welding into Forming and continue modeling a forming process. The company says this method offers minimal effort to achieve a consistent process chain simulation. Users can exchange or transfer data between different Simufact Forming processes. Users can import selected processes with all process properties intact, and use them for subsequent calculations. Version 16 also provides enhanced flexibility, allowing ability to share results with any CAE product. Exported simulation results can be used in other products, such…