Editors’ Picks

Found in Robotics News & Content, with a score of 5.72

…the company's investment in surgical robot maker Kinova and welding robot maker Norvac Technologies. Companies need to be flexible during uncertain times Adam Kelson While he is not an investor directly, Adam Kelson helps advise companies as a lawyer at K&L Gates LLP. Given how volatile the market is, he is advising his clients to be more flexible. “I don't think anyone knows what the future's going to bring next week, let alone in the three to six months,” Lelson said. “They really need to be open to hearing what investors are telling [them] and not being offended. ... You…

Found in Robotics News & Content, with a score of 10.61

…to perform demanding tasks such as machine maintenance and welding. It can also handle multiple devices simultaneously. The CS620's high trajectory accuracy and wide reach, which ensures that large components can be smoothly welded without using an external axis, said the company. Like all other models in the CS series, the CS620 robotic arm features an IP65 degree of protection, upgradeable to IP68. Rated for ISO Class 5 cleanrooms, the CS Series is suitable for industries that require the highest level of hygiene, such as pharmaceutical and electronics. Elite Robots said it will premiere the CS620 in the U.S. in…

Found in Robotics News & Content, with a score of 10.27

…robot's seventh axis, or “wrist joint,” enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm, said the company. The seventh axis also gives the KR1805 a small footprint of 160 x 160 mm (6.2 x 6.2 in.). This provides “a huge advantage in maneuverability” and an increased range of motion for tasks such as bin picking, packaging tasks, and labeling, asserted Kassow. The safety-compliant design allows the KR1805 to share a workspace with humans following a safety evaluation of the site where the system will be implemented, the company noted.…

Found in Robotics News & Content, with a score of 8.05

…advantage of some semi-automated processes for CNC machining and welding, but it's hoping to invest in a robotic arm or two to help with welding and cutting. Helfrich Brothers Boiler Works, like many small and medium-sized enterprises, is looking to automation to help increase productivity and throughput and to address labor challenges. And like other smaller companies, it's looking to outside sources to help pay for them. Helfrich looks to state to help fund robot project Helfrich Brothers Boiler Works is one of many of Massachusetts companies that applied for a Massachusetts Manufacturing Accelerate Program grant (MMAP). The program is…

Found in Robotics News & Content, with a score of 11.86

…a robotic welder, it considered several automated and traditional welding companies and ultimately decided on a unit from Hirebotics. The key factor in the decision was ease of use. “When we started looking into the technology, we saw just how easy these robots were to operate,” recalled Montes. “That was the real game changer for me. From my perspective, it would be a waste of time and money acquiring a robot, only to have it sit unused because it was too hard to operate.” To achieve ease of use, a number of design techniques come into play. “Hirebotics’ cobot runs…

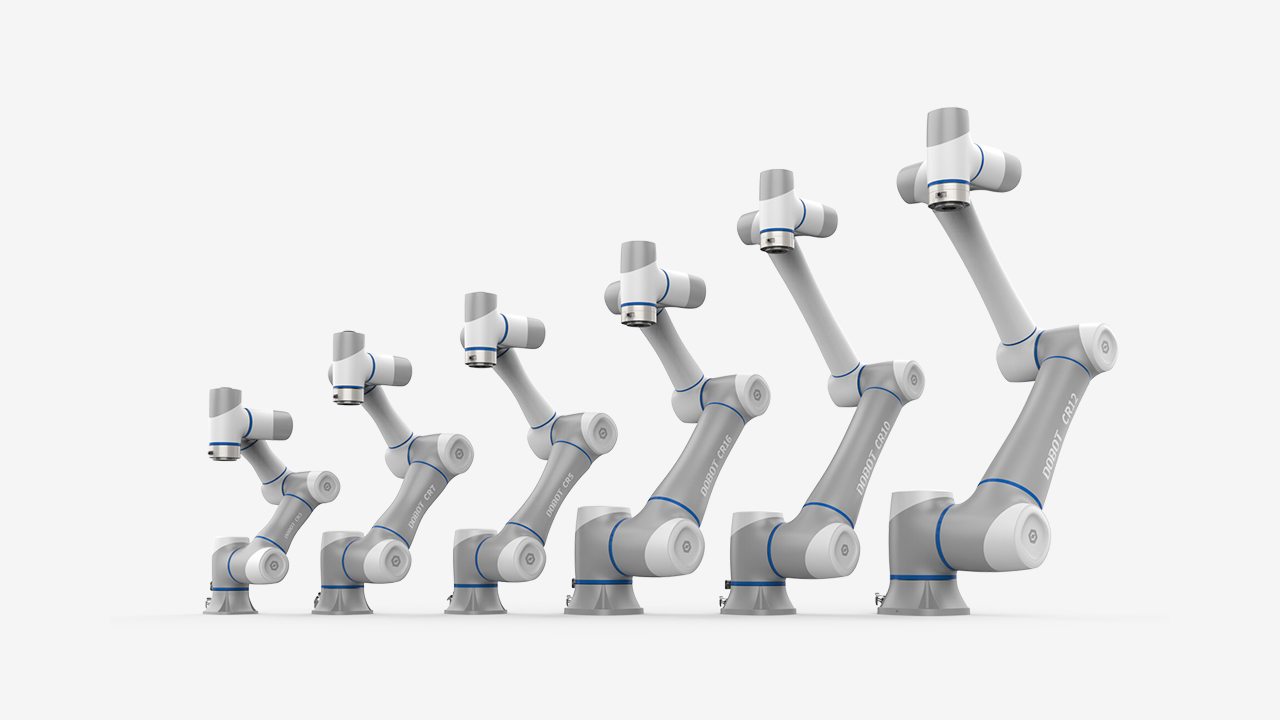

Found in Robotics News & Content, with a score of 16.16

…palletizing, as well as large-sized workpiece machining and long-seam welding in complex scenarios. Hannover Messe is hosted and organized by Deutsche Messe AG. This year's industrial trade show runs from April 17 to April 20 and features more than 2,500 exhibitors and some 66,4000 attendees. CR20A has minimal residual vibration Based on new-generation technology and advanced dynamic algorithms, the CR20A's residual vibration is reduced by 50% during high-speed stops and has enhanced reliability to greatly improve production efficiency in heavy-load scenarios, the company said. Dobot noted it has developed dedicated process package software for palletizing, welding, and other complex tasks.…

Found in Robotics News & Content, with a score of 7.25

…and electronics. For example, automakers use CNC robots for welding, painting, and handling parts. The integration of CNC machining and automation offers several advantages, such as: Increased productivity Reduced labor costs Improved quality Increased flexibility Reduced cycle times Increased throughput Automation of material handling and part loading Despite the many advantages of integration, some challenges must be overcome. They include: High initial costs Need for specialized skills and expertise Comprehensive training programs for operators and maintenance personnel The complex and time-consuming integration process Requires careful planning and coordination Potential disruptions during the integration process Limited ability to adapt to changes…

Found in Robotics News & Content, with a score of 8.87

…and palletizing Piece picking and perception Machine tending and welding with collaborative robots RAC ’22 included presenters from integrators and end users such as Körber Supply Chain, GXO Logistics, and Toyota North America. Attendees included leading global companies including Ahold Delhaize, Amazon, Cargill, Carrier, Fuji, Garmin, General Mills, HomeGoods, Johnson & Johnson, the Mayo Clinic, and Starbucks. In addition, Aaron Prather, director of the Robotics & Autonomous Systems Program at ASTM International, delivered the keynote address on optimizing warehouse operations with robots and AI. He was previously former senior advisor for technology research and planning at FedEx. This year’s event…

Found in Robotics News & Content, with a score of 19.69

…for sandblasting, thermal spraying, shot peening, sanding, polishing, and welding applications at the show at Hall 11 Stand A45. The company said it is attending the show to help expand its presence in the European market and better demonstrate its simplified robot programing solutions. Augmentus claimed to serve a diverse customer base across various industries, such as aerospace, automotive, maritime, and supply chain. Its systems are used by companies such as ST Engineering, Hyundai, Abrasive Engineering, Johnson & Johnson, and Fujitsu. Augmentus aims to make automation simpler The company was established in 2019 and claims to be a pioneer in…

Found in Robotics News & Content, with a score of 6.08

…ease of integration, not people handing parts to a welding robot, and there's a huge shortage of skilled labor like welders.” “Modern applications incorporate ease of use, the right price point for small customers, and robots that they can understand and build into their operations,” he asserted. “We're getting there. There's still some vertical integration to do with our supply chains to be more responsive, and there's a shortage of integration skills.” A rendering of the lobby of ABB's planned U.S. expansion. Source: ABB Michigan anticipates job growth ABB already has about 350 employees at Auburn Hills. The expansion will…

Found in Robotics News & Content, with a score of 6.81

…tasks and processes such as piece picking, palletizing, and welding, but the amount of human-machine interaction for each should be the result of deliberate choice. For instance, in goods-to-person (G2P) applications, the robots move materials, while employees do the picking, guided by intuitive user interfaces. As robotics and AI grow more capable, executives, operators, and floor associates must decide whether to fear innovation or work with them as tools to solve problems. “Instead of letting technology run its course as if we have no say and the future was predetermined, we must actively create the future we want. It is…

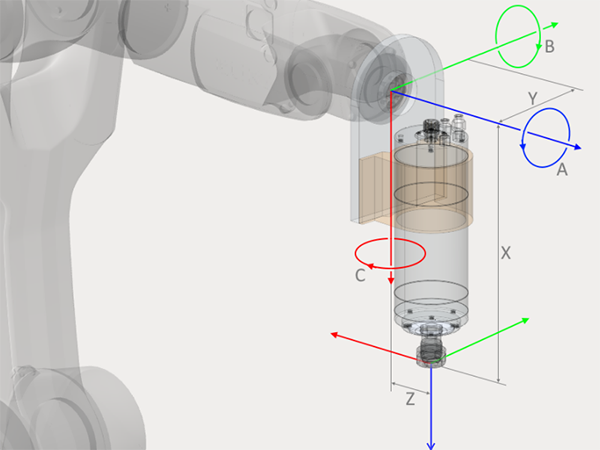

Found in Robotics News & Content, with a score of 8.85

…and accurately perform tasks such as cutting, drilling, and welding in the correct location, said SprutCAM Tech. The calibration process typically involves measuring the positions of various points on the tool and using these measurements to calculate the position of the TCP. SprutCAM said its app uses the “double-spikes” method for calibration. The double-spikes method is a TCP calibration method used in robotic and machine tool applications. It consists of measuring two points on a probe and calculating the position of the tool center point based on these measurements. Measurement of the position of the long tool. The position of…