Editors’ Picks

Found in Robotics News & Content, with a score of 6.54

…structures with respect to environmental impact, architectural freedom, and manufacturing costs,” said Mark Girolami, program director for data-centric engineering at the Turing. MX3D Smart Bridge in Amsterdam center. Credit: Thea van den Heuvel Government helped enable innovation As governments worldwide strive to build smarter cities, this research project will help experts improve the design, operation, and safety of future 3D-printed structures and IoT systems under all conditions, said the partners. MX3D noted that the support of the city of Amsterdam, stadsdeel Centrum, and its chief technology office were essential to the project's success. In addition, the project enalbed the company…

Found in Robotics News & Content, with a score of 19.22

…of precision metrology, inspection, and assembly products for advanced manufacturing. Wilsonville, Ore.-based DWFritz designs, builds, and supports engineered-to-order, high-speed, non-contact metrology and automation systems. “This is in line with our strategic focus to grow organically and through acquisitions in the advanced manufacturing space, with special focus on industrial software, industrial metrology, and additive manufacturing solutions,” stated Stefan Widing, president and CEO of Sandvik. DWFritz Automation has offices in France and China. The company said it has many Fortune 500 customers and more than 2,000 systems installed worldwide. In 2020, the company had about 560 employees, revenues of approximately SEK 720…

Found in Robotics News & Content, with a score of 16.32

…SA, a pioneer in multi-material deposition systems for powder-based additive manufacturing (AM) systems. “This transaction advances our strategy to own differentiated print technologies that enable an expanding set of AM 2.0 applications at scale,” stated Ric Fulop, founder and CEO of Desktop Metal. “Multi-material printing is the next frontier in AM. Today, people print parts, but in the future, people will look to print full products, which may be composed of multiple materials. Industrializing Aerosint’s core technology and related powder-processing systems will provide many benefits to the broad adoption of AM solutions.” Founded in 2016, Aerosint offers a system based…

Found in Robotics News & Content, with a score of 25.03

VELO3D Inc., which specializes in additive manufacturing for metal parts, today said that Vertex Manufacturing, a provider of CNC machining and manufacturing services from development through production, has chosen it to help meet growing demand for 3D-printed “impossible” metal parts. “At VELO3D, we help innovators like Vertex accelerate the future of manufacturing, not just for their customers, but to benefit all of humanity,” stated Benny Buller, founder and CEO of VELO3D. “This new partnership speaks to the real and transformational capabilities VELO3D is bringing to metal additive manufacturing.” Founded in 2014, VELO3D offers fully integrated, patented systems including the Flow…

Found in Robotics News & Content, with a score of 20.80

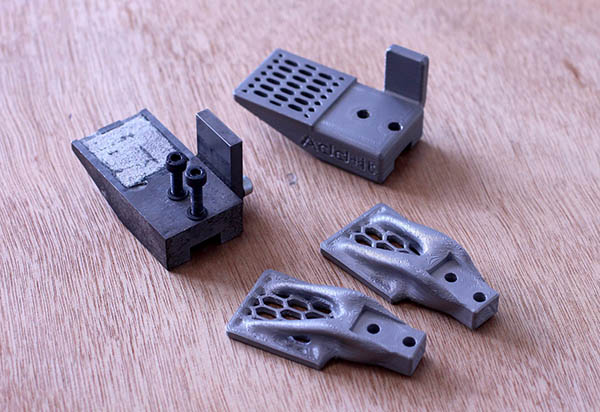

A key part of digital manufacturing is the use of software and hardware that can be readily modified for flexible production. Preziosa Francesco SRL, a sheet metal manufacturer, wanted to create custom robotic grippers for each job. Conventional machining would take too long, so the Bergamo, Italy-based company turned to 3D printing with the help of Additive Italia SRL, Desktop Metal Inc., and nTopology Inc. Preziosa Francesco realized that CNC machines would require long lead times to create new grippers for its existing robotic cell and automated press bending machine. The company worked with design engineers from Additive Italia (Add-it)…

Found in Robotics News & Content, with a score of 7.37

…a reason why a lot of people think about additive manufacturing, because they're not constrained by the limits of molding. It gives companies new design freedom.” Micro technology for massive impact Fang has been studying properties of light and microfabrication for more than 20 years. For the past 10 of those years, he has been a faculty member at the Massachusetts Institute of Technology. A big part of his work, which takes place in MIT's Nanophotonics and 3D Nanomanufacturing Laboratory, involves studying common 3D printing approaches that expose a material to light to harden, or cure, it. One such approach,…

Found in Robotics News & Content, with a score of 10.96

…center and an institute focused on advanced materials and manufacturing at Hazelwood Green, a former riverside steel mill site. It will attract the jobs and industries of the new economy, while enabling development of a true mixed-use destination that will be a positive and inclusive part of Hazelwood, said the partners. “Pittsburgh’s future — and the future of U.S. innovation and global competitiveness — are inextricably linked to scientific and technological advances and how well organizations, communities, and industries can stay ahead of the rapid pace of change,” stated Farnam Jahanian, president of CMU president. “Carnegie Mellon is positioned at…

Found in Robotics News & Content, with a score of 28.06

…Adaptive3D Technologies LLC, a provider of elastomeric solutions for additive manufacturing. Adaptive3D's products enable the high-volume production of end-use parts through additive manufacturing using odorless, tough, strain-tolerant, tear-resistant, and biocompatible rubbers and rubber-like materials. Adaptive3D offers additive manufacturing polymer resins and specialty polymers to companies around the world in the consumer, healthcare, industrial, transportation, and oil and gas sectors. The company claimed to be a leader in printing and processing rubber-like materials, damping materials, and low-cure stress photopolymers. “The acquisition of Adaptive3D advances Desktop Metal’s vertical integration strategy to grow our portfolio of materials and expand the high-volume applications supported…

Found in Robotics News & Content, with a score of 22.23

…Training Board with multiple robots for the new Advanced Manufacturing Training Centre of Excellence (AMTCE), touted as “the largest vocational training facility of its kind in Europe.” According to KUKA, the training facility will be well-stocked with robots, including customized six-axis industrial robots with vision systems, robot welding cells, robot milling/machining cells, and collaborative robot cells. The center will be the site of new training courses designed to retrain operators and technicians. This comes at a time when industrial manufacturing and metal cutting is undergoing an automation renaissance with greater implementation of Industry 4.0. It's also part of the Irish…

Found in Robotics News & Content, with a score of 14.01

The Advanced Robotics for Manufacturing, or ARM Institute today announced that Dr. Jared Glover, CEO of CapSen Robotics, has been selected as the institute’s first fellow. As an ARM Institute Fellow, Glover will execute a technical project to address key challenges hindering the adoption of robotics in manufacturing. The new fellowship program supports the Artificial Intelligence in Metals and Manufacturing (AIM) Higher Consortium. That group is led by the Catalyst Connection and is intended to help small and midsize manufacturers that supply or are pursuing opportunities with the U.S. Department of Defense (DoD). First ARM Institute Fellow Glover is co-founder…

Found in Robotics News & Content, with a score of 11.44

…Northeast Ohio region. Freshmade 3D has also received development support from America Makes, part of the National Network for Manufacturing Innovation established by the Revitalize American Manufacturing and Innovation Act of 2014. “We’re so proud to be a part of Freshmade 3D’s success,” said Barb Ewing, CEO of the Youngstown Business Incubator. “Two of the three founders started their entrepreneurial career as part of our team. They are proof that Northeast Ohio is fast becoming the epicenter for additive manufacturing in North America.”

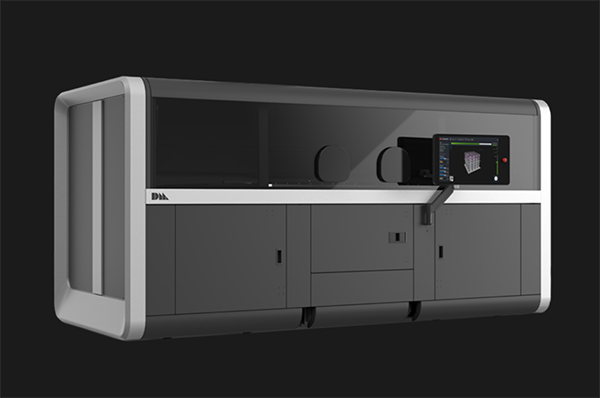

Found in Robotics News & Content, with a score of 20.98

…to achieve the fastest build speeds in the metal additive manufacturing market, claimed the Burlington, Mass.-based company. “The qualification of 316L stainless steel with leading mechanical properties on the Production System platform is part of our aggressive roadmap to support an array of materials for binder jetting,” stated Jonah Myerberg, co-founder and chief technology officer of Desktop Metal. “[It is] a testament to the advantages of SPJ technology, which enables mass production throughput without sacrificing part performance and repeatability.” “With 316L on the Production System P-50, businesses will now be able to leverage additive manufacturing to produce complex, end-use parts…