Desktop Metal Inc. yesterday announced that its Production System is qualified to use 316L stainless steel. The system uses patent-pending Single Pass Jetting (SPJ) technology to achieve the fastest build speeds in the metal additive manufacturing market, claimed the Burlington, Mass.-based company.

“The qualification of 316L stainless steel with leading mechanical properties on the Production System platform is part of our aggressive roadmap to support an array of materials for binder jetting,” stated Jonah Myerberg, co-founder and chief technology officer of Desktop Metal. “[It is] a testament to the advantages of SPJ technology, which enables mass production throughput without sacrificing part performance and repeatability.”

“With 316L on the Production System P-50, businesses will now be able to leverage additive manufacturing to produce complex, end-use parts suitable for use in harsh environments at volumes and costs competitive with conventional manufacturing,” he added.

As 3D printing evolves from rapid prototyping to mass production, it promises to transform engineering and manufacturing, said Desktop Metal. Experts in advanced manufacturing, metallurgy, and robotics founded the company in 2015 to address challenges of speed, cost, and quality.

316L stainless steel supports key applications

316L stainless steel is known for its corrosion resistance and excellent mechanical properties at extreme temperatures, according to Desktop Metal. It is suitable for parts exposed to marine or pharmaceutical-processing environments, food-preparation equipment, medical devices, and surgical tooling. It also exhibits excellent weldability by standard fusion and resistance methods, the company said.

Through extensive testing, the Desktop Metal materials science team has validated that 316L stainless steel printed on Production System technology and sintered by Desktop Metal meets MPIF 35 standards for structural powder metallurgy parts set by the Metal Powder Industries Federation. Parts printed with 316L can also significantly reduce production time and part cost, said the company. It cited the following example appplications:

Rocker arm for saltwater environments

Rocker arms are used to open and close intake and exhaust valves on an outboard marine engine. The use of 316L could extend the part’s life and provides corrosion resistance against harsh saltwater environments.

The P-50 enables the production of more than 1,000 parts per day, said Desktop Metal. This includes ribbing features and cutouts to deliver adequate strength and stiffness while maintaining low weight and a small footprint in comparison the standard cast alternatives, which can require up to eight to 14 weeks of lead time.

.jpg)

Fluid connector for chemical processing

Heavy industry fluid connectors used in many chemical processing plants need to be manufactured in 316L for corrosion resistance against the chemicals moving through the part.

The connector’s complex internal channels make it impossible to manufacture as a single component via conventional manufacturing methods.

The Production System P-50 enables printing the fluid connector in 316L as a single, consolidated component. It can support a throughput of nearly 5,500 parts per week, at a fully burdened cost of approximately $6.85 per part, Desktop Metal said

Customized surgical tools

Because 316L is a surgical-grade steel, it is an ideal material for medical applications like surgical nozzles. By eliminating tooling, additive manufacturing enables mass-production runs of different-sized nozzles with no lead time, featuring internal channels that are optimized for individual patient needs.

Printing on the Production System P-50 can eliminate multiple fixturing steps otherwise required for machining, resulting in a throughput of more than 24,000 parts per week at approximately $2.50 per part, said Desktop Metal.

By comparison, machining the same part would cost $20 to $40 per part and require up to two months to create the same number of parts that the P-50 can produce in just one week.

Automotive gear-shift knobs

High-touch parts like these gear knobs (see below) require materials that are easy to sanitize. 316L offers corrosion resistance and cleans easily, said Desktop Metal. A textured gear shift is an example of mass customization made possible by binder jetting on the Production System, which supports up to 200 parts per build and up to 6,700 parts per week. By comparison, casting would require eight to 14 weeks lead time for tooling, just to begin volume production.

“As innovators in the automotive, medical, consumer products, and petrochemical industries continue to embrace the benefits of additive manufacturing, implementing applications made possible with 316L stainless steel, we will begin to see even more widespread adoption of binder-jetting technology,” said Myerberg. “Materials that push the boundaries of what AM technology can do will continue to advance the industry and drive unparalleled throughput while significantly reducing cost and waste.”

Production System 'world’s fastest way to 3D-print metal parts at scale'

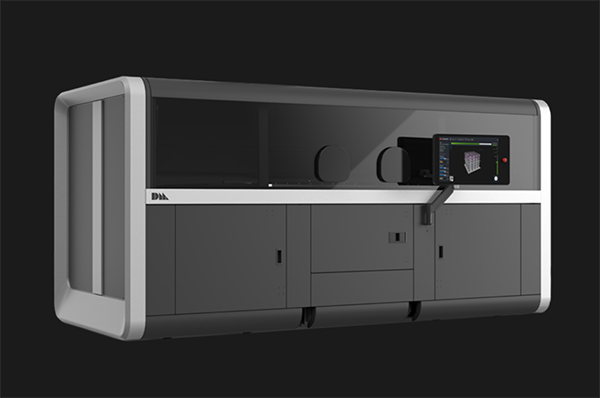

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System is an industrial manufacturing platform powered by Desktop Metal’s SPJ technology. It is designed to achieve speeds up to 100 times those of legacy powder-bed fusion additive manufacturing technologies.

The system can also enable production quantities of up to millions of parts per year at costs competitive with conventional mass-production techniques, said the company.

The Production System consists of two printer models: the P-1 for process development and serial production applications, and the P-50, a large mass-production solution for end-use parts, scheduled to begin commercial shipments in 2021.

The system combines Desktop Metal-engineered binders with an open material platform, allowing customers to produce high-performance parts using the same low-cost metal powders used in the metal injection molding (MIM) industry.

An inert processing environment enables compatibility with a variety of materials, including the now-qualified 316L stainless steel as well as high-performance alloys and even reactive metals, such as aluminum and titanium, said Desktop Metal.

Article topics

Email Sign Up