Editors’ Picks

Found in Robotics News & Content, with a score of 21.63

…“There were many problems to solve, such as in machine tending, where a cobot doesn't know exactly where things are. Then there were the machine vision challenges, such as with lighting. Figuring out where to put a camera takes a bit of engineering before you start training.” “Any time you're dealing with variance in machine position, color, or place, the user can train MIRAI to understand what images mean and how to behave,” Vuine said. “Just connect camera to the robot's wrist and guide the arm to points. It watches and generalizes what it has been shown and knows where…

Found in Robotics News & Content, with a score of 21.59

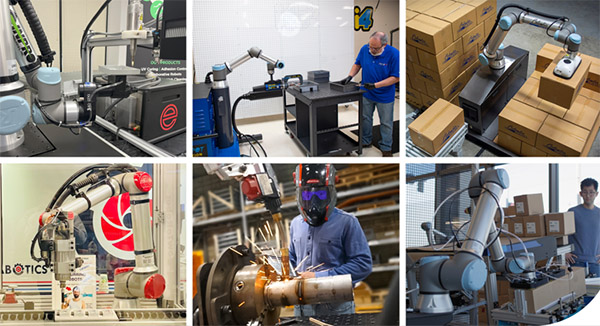

…to use. Tasks or applications growing in popularity include machine tending and welding. Coupled with the labor shortage and an aging workforce, more and more businesses are starting to see the value of industrial automation. Top shops around the world Many of the top industrial automation providers are based in Asia or Europe, rather than in North America. Some examples include Zurich, Switzerland-based ABB Group and Kitakyushu, Japan-based Yaskawa. They are big companies with employees ranging in the thousands, and each has U.S. offices. The biggest robotics vendors have billions of dollars in annual revenue. As these companies get bigger,…

Found in Robotics News & Content, with a score of 21.23

…partner of Universal Robots. Robert E. Morris is a machine tool distributor and sells CNC machines and other industrial equipment, said Mike Locke, productivity specialist at the Morris Group. Its other partners include Tsugami, Okuma, Trumpf, Geminis, Soraluce, Momentum, Velocity, National, MP Systems, Chevalier, and Desktop Metal. Morris teamed up with Universal Robots two years ago as more of its customers requested automated systems in response to the pandemic. “It’s excellent pairing—– putting robots on CNC machines,” he said. “It’s just an excellent partnership having robots on board to help serve our customers and what they need to do.” Here’s…

Found in Robotics White Papers & Archives, with a score of 20.99

…have found particular success in high-mix, low-volume applications like machine tending, piece picking and welding. This issue takes a deep dive into the cobot space, with features focused on how Collaborative Robots recently raised $30 million to launch its new Cobot Flywheel Program and develop its “practical cobot.” The program is focused on helping biotech, healthcare and logistics companies drive ambitious operational transformation with advanced robotics solutions. You’ll also learn how Omron Automation Americas is partnering with Jet Automation Inc., to jointly develop a new cobot palletizing system, and how Solo Brands is working with Locus Robotics to deploy 16…

Found in Robotics News & Content, with a score of 20.50

…managing director at Angeles Equity Partners. Acieta expands Angeles’ machine tending, palletizing, and welding offerings across a broader set of end markets including agriculture, foundry and die, welding and fabrication, and construction and building products. Acieta offers standardized and customizable robots Headquartered in Waukesha, WI, Acieta is a full-service industrial automation provider with systems, controls and software engineering capabilities. Since 1983, Acieta has built a large standardized robotics business and installed over 5,500 robots. “Our team is eager to help build what we believe is the country’s most technically capable and experienced automation systems integrator,” said Robby Komljenovic, Acieta CEO.…

Found in Robotics News & Content, with a score of 20.38

…parts to be placed into a CNC machining process. “Machine tending is a critical process in manufacturing and one of the most popular applications for UR cobots,” said Joe Campbell, senior manager of applications development at collaborative robotics leader Universal Robots, in a press release. “By constantly feeding the cobot new parts to accurately pick and place, Applied Cobotics optimizes this process significantly,” he added. “We’re excited to include the Cobot Feeder in the UR+ product portfolio, benefitting our rapidly growing customer base looking to automate this task.” PBC Linear has been a proud member of the manufacturing community in…

Found in Robotics News & Content, with a score of 20.30

…UR20 will be “loading and unloading workpieces into a machine fixture requiring a long reach” at its booth. The company said it re-engineered the cobot’s joint to deliver 30% more speed and torque within a closed capsule. In fact, the UR20’s base joint can produce 700 Newton-meters of torque, noted Anders Beck, vice president of innovation and strategy at Universal Robots. “This is more than a performance model Tesla produces on all of its wheels,” he said in a statement. “Even with the increase in reach and torque, we’ve managed to retain the cobot’s 50 microns repeatability, while using standard…

Found in Robotics News & Content, with a score of 20.05

…control) equipment, learning to program, set up, and operate machines that produce parts for industries including aerospace, medical, defense, and automotive. The expanded coursework provides technical skills training in robotic programming and various collaborative robotic tasks such as machine tending. The 40,000 square-foot workforce training facility offers an accelerated five-month program for adults and a 10-month program for young adults. The Robotics Center has the support of many companies that operate in the robotics and automation space, with many of them providing robots, software, services, and accessories. Sponsors and supporters of the new center include: Teradyne, owner of Universal Robots…

Found in Robotics News & Content, with a score of 19.94

…tools in every process, from quality assurance to press tending. For one, robotic metal stamping technology can reduce overhead expenses dramatically. Multiple in-die sensors equipped with artificial intelligence can detect and report defects immediately, preventing material waste. Since inconsistencies of an imperfect die raise production costs substantially over time, an automated system with instant feedback is an ideal solution. Although in-die sensing initially came to exist as a solution to die crashing, manufacturers soon realized it could evolve into something more. Now, it can monitor various metal stamping processes with extreme precision. For example, analog-output proximity sensors can measure materials…

Found in Robotics News & Content, with a score of 19.45

…will be able to see the latest in robotics, machine vision, artificial intelligence (AI), and motion control. ABB Robotics is continuing the expansion of its modular large robot portfolio with the introduction of its new IRB 7710 and 7720. The new robot arms, combined with recently launched IRB 5710 through 5720 and IRB 6710 through 6740 models, offer a combined total of 46 different variants capable of handling payloads between 70 and 620 kilograms, or about 150 to 1,350 pounds. “As businesses introduce new technologies and components to meet productivity and sustainability goals, we’ve engineered our modular large robot portfolio…

Found in Robotics News & Content, with a score of 19.41

…customer success team will gain full awareness of the machine, from the hardware and firmware versions and the real-time I/O state to the program running on Vention’s MachineMotion controller. This ensures that user guidance will be efficient and timely, said the company. Vention claimed that its customer success team provides above 96% in terms of responses within the promised time. With more than 16,000 equipment pieces already deployed, the company asserted that it consistently achieves a net promoter score above 75. Vention cited the following features and technical advancements in Pendant V3 that will allow manufacturers to benefit from the…

Found in Robotics News & Content, with a score of 19.32

…will show the UR20 at its booth in a machine tending application, loading and unloading heavy workpieces into a machine fixture. Universal Robots collaborated with Pro Spot International for the first spot welding application. Source: Universal Robots New takes on palletizing, case packing Manufacturers looking to verify whether a UR cobot palletizer will work for their applications can now receive a complete project analysis with performance and installation data delivered right in UR’s booth. With MyRobot.cloud, Rocketfarm is launching the first digital twin designed for palletizing with UR cobots. Integrators can now quickly verify customer projects on site. The system…