Editors’ Picks

Found in Robotics White Papers & Archives, with a score of 36.16

…edge, autonomous systems are becoming more capable. Learn about how robots are becoming more capable for applications such as machine tending, pick-and-place operations, and welding. The free download also examines how these technologies are improving robot and vehicle navigation. In addition, automation is spreading beyond manufacturing to for agriculture, e-commerce, and more. Topics covered include: Innovations in cameras, lidar, and collaborative robotics How picking robots are getting faster and more accurate AI and programming enable more thorough inspections Robotics providers receive recognition as innovators How robots are shaping the future of industry

Found in Robotics News & Content, with a score of 13.74

…to do more things, such as welding, palletizing, and machine tending, explained Richard Vaughn, a senior automation engineer at Bosch Rexroth Corp. and a member of the American Society of Mechanical Engineers (ASME). “Programming their movements in 3D is complex, so software typically maps the motion to a set of world coordinates, in which the origin sits on the pedestal’s first joint axis,” he said. Five- and six-axis: The sweet spot? Four-, five-, and six-axis robots offer a higher degree of freedom. Most industrial robots today are either five- or six-axis. They can move along all three axes and turn…

Found in Robotics News & Content, with a score of 20.30

…UR20 will be “loading and unloading workpieces into a machine fixture requiring a long reach” at its booth. The company said it re-engineered the cobot’s joint to deliver 30% more speed and torque within a closed capsule. In fact, the UR20’s base joint can produce 700 Newton-meters of torque, noted Anders Beck, vice president of innovation and strategy at Universal Robots. “This is more than a performance model Tesla produces on all of its wheels,” he said in a statement. “Even with the increase in reach and torque, we’ve managed to retain the cobot’s 50 microns repeatability, while using standard…

Found in Robotics News & Content, with a score of 16.74

…remain challenging for piece-picking operations. Advances in computer vision, machine learning, and end-of-arm tooling are now enabling robots to pick at human and even superhuman rates. One company focusing on successful automation of pick-and-place workflows is Material Handling Systems Inc. (MHS). The Mt. Washington, Ky.-based company spun out MHS Robotics from its research and development unit last year. Kristiyan Georgiev, R&D manager for computer vision and software engineering at MHS, spoke with Robotics 24/7 about improvements in robotic picking applications. How long have you been at MHS, and how does your prior experience help you manage these technologies? Georgiev: I…

Found in Robotics News & Content, with a score of 17.35

…(Bill) Twickler, vice president of solutions at GXO Logistics Machine Tending and Welding With Cobots: Josh Pawley, founding partner at Vectis Automation, and Brian Havey, director of sales at VersaBuilt Robotics Piece Picking Gets Faster With Robotic Perception: Sandeep Sakharkar, CIO of GXO Logistics Other sessions include “Palletizing and the Next Frontiers for Mobile Robots.” More speakers will be announced soon, and qualified experts can still apply to participate. Register now for the Robotics Applications Conference The Robotics Applications Conference is free, and registration is now open for all sessions. Visit Robotics 24/7 for the latest news about the commercial…

Found in Robotics News & Content, with a score of 32.43

…ABB Value Provider MESH Automation; a vision guided FlexLoader machine tool tending cell; and the Cobot FlexTrainer education cell for interactive classroom training. “ABB has continually developed cutting-edge products and support programs to help a wide variety of manufacturers and their employees become more productive, resilient and adaptable. Our IMTS exhibit will showcase a number of these innovations, many of which have opened up robotic automation to a broad group of first-time users,” said Joe Chudy, U.S. general manager at ABB Robotics. “Now, more than ever, businesses of all sizes need to embrace robotics to efficiently adapt production to satisfy…

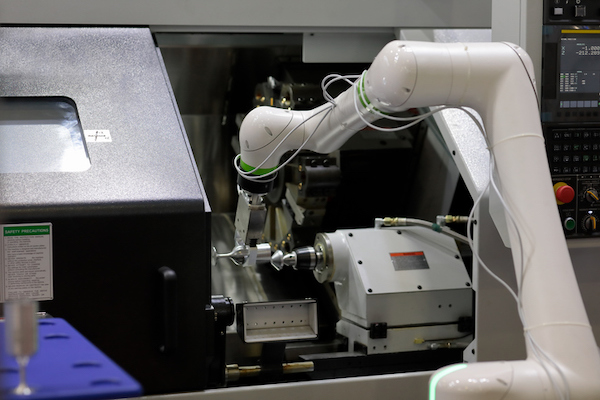

Found in Robotics News & Content, with a score of 21.23

…partner of Universal Robots. Robert E. Morris is a machine tool distributor and sells CNC machines and other industrial equipment, said Mike Locke, productivity specialist at the Morris Group. Its other partners include Tsugami, Okuma, Trumpf, Geminis, Soraluce, Momentum, Velocity, National, MP Systems, Chevalier, and Desktop Metal. Morris teamed up with Universal Robots two years ago as more of its customers requested automated systems in response to the pandemic. “It’s excellent pairing—– putting robots on CNC machines,” he said. “It’s just an excellent partnership having robots on board to help serve our customers and what they need to do.” Here’s…

Found in Robotics News & Content, with a score of 31.98

Kassow Robots, a developer of 7-axis cobot systems for machine tending, material handling, and related applications, announced last that week that its KR1018 7-axis cobot is being deployed as part of a solution to automate the textile industry. The 7-axis KR1018 has a payload of 18kg (39 lb.) and a reach of 1000 mm (39 in.), making it the ideal machine to complete precise and repetitive industrial tasks that require great strength, the company said. An AGV/cobot combo system The cobot will be mounted on an AGV equipped with a magazine and control system and used to restock cabling machines,…

Found in Robotics News & Content, with a score of 18.28

Kassow Robots, a developer of 7-axis cobots for machine tending, material handling, and related applications, has partnered with Industrial Control, a factory automation distribution specialist with over 46 years of experience. Zeeland, Mich.-based Industrial Control said it sells over $12 million in automation components and solutions annually in the state of Michigan. The company’s other robotic partners include Epson Robots, Mobile Industrial Robots, Asyril, Intelligent Actuator Inc., Solomon, Nachi Robotic Systems, and Shunk. “Industrial Control is a perfect partner for intelligent robotic solutions,” said Dieter Pletscher, head of global sales at Kassow Robots. “To ensure success, their team utilizes the…

Found in Robotics News & Content, with a score of 32.95

…that robotics can play in plastics injection molding: 1. Machine tending A common application for pick-and-place systems is the loading and unloading of products into packaging. In plastics, machine tending robots can unload finished parts from the injection-loading machine and deliver them to downstream processes. Using pick-and-place automation, such as Cartesian robots and Delta robots, can reduce the risk of injuries to laborers, as well as improve product consistency and production capacity. 2. Insert molding Insert molding is another task often handled by robots. Insert molding entails enclosing an “insert” such as a pin, blade, or threaded rod in molded…

Found in Robotics News & Content, with a score of 26.50

…what might this look like as a practical example? Machine tending as a model If we look at the now-mature robot application of CNC machine tending, we see that it’s presently addressed with a general-purpose, six degree-of-freedom (DoF) arm that is not optimized for any specific CNC machine. It involves integration, personnel training, custom tooling, and myriad other friction points or barriers to entry. Several options are available, including choices of robot make, size, and internal or external integration partner. This and other steps can quickly add up to a custom project, improving productivity but not necessarily optimization. There is…

Found in Robotics News & Content, with a score of 31.86

…and a large showroom filled with robotic and CNC machine demonstrations. FANUC Mexico will demonstrate a variety of automation technologies designed to help customers increase their production capabilities, overcome labor challenges, and remain competitive, including: Collaborative tote picking —A FANUC CR-15iA collaborative robot using an overhead-mounted iRVision 3DV/600 Vision Sensor will pick random consumer products from a tote and place them into an outfeed tote. It will demonstrate the sensor's speed and accuracy, as well as its ability to detect and pick a variety of products, similar to applications found in warehousing and distribution. Hands-on collaboration —A FANUC CRX-10iA cobot…