Editors’ Picks

Found in Robotics News & Content, with a score of 14.37

…mixed-case pallets. A DAC Robotics ABOT (automated box opening technology), which features box metrology and dimensional capture to ensure precision opening of a wide range of box sizes and types prior to decant. A DAC Robotics precision decanting system. DAC offers fully automated precision handling of the most delicate glassware and foil packs to semi-automated designs that allow for necessary operator re-pack and consolidation functions, or additional process work to optimize and utilize the highest percentage of a re-packed tote’s capacity. Want to learn more about cobot arms? This article was featured in the April 2024 Robotics 24/7 Special Focus…

Found in Robotics News & Content, with a score of 14.06

…dental, photopolymer and 3D printing capabilities to deliver productivity, precision and performance 3D printing solutions to the dental market. This new combination comes with Keystone’s FDA-cleared night guard resin, KeySplint Soft and KeyModel Ultra, a material for next-gen dental and orthodontic models along with the rest of Keystone’s laboratory and medical device printing materials, including KeyTray and KeyGuide. All Keystone precision dental resins are manufactured in the USA, and available immediately through Nexa3D’s expanding global channels. “During our extensive internal optimization and validation testing, we confirmed that the NXE 400 produces outstanding quality prints at high volumes, making it an…

Found in Robotics White Papers & Archives, with a score of 14.05

…depends on supply chains operating at the highest-levels of precision possible. Materials arrive on-site just before manufacturing commences, enabling production operations to stay lean and squeeze maximum output out of available space, but leaving little slack time or margin for error. This paradigm pressures each piece of the supply chain to hold up its end of the bargain, from shipping vessels to materials handling equipment. The COVID-19 pandemic presented unique challenges to global supply chains, with lockdowns and public health effects wreaking havoc and causing delays for finely tuned manufacturing operations. But that was just the beginning – semiconductor and…

Found in Robotics News & Content, with a score of 14.02

…in Asia for that growth. Han's Robot cobots promise precision Human-robot cooperation is essential to improve efficiency and the working environment, according to Han's Robot. The company said its Elfin collaborative robots are designed to be easy to program and operate, saving time and cost. In addition, Han's Robot said its cobots are useful for processes such as plane welding, three-dimensional welding, and arc welding. They can handle various parts and workpieces with high precision, reduce the workload of human welders, and integrate production and operations, noted the company. Han’s Robot said its automated arc welding robots can be applied…

Found in Robotics News & Content, with a score of 13.97

…to minimize material loss, almost anything is possible with high-precision technology like this. Why Manufacturers Adopt Robotic Metal Stamping Robotic metal stamping is rapidly becoming an industry standard addition to plant floors. Facilities can use it for various applications like sheet unstacking or die inspection. In comparison to traditional methods, it has enhanced flexibility and a wider range of benefits. Toni Roda — global product manager at ABB — discussed the biggest problems in the sector, stating, “Many stamping companies are looking to implement some form of robotic automation but are unsure of where to start.” After all, manufacturers have…

Found in Robotics News & Content, with a score of 13.69

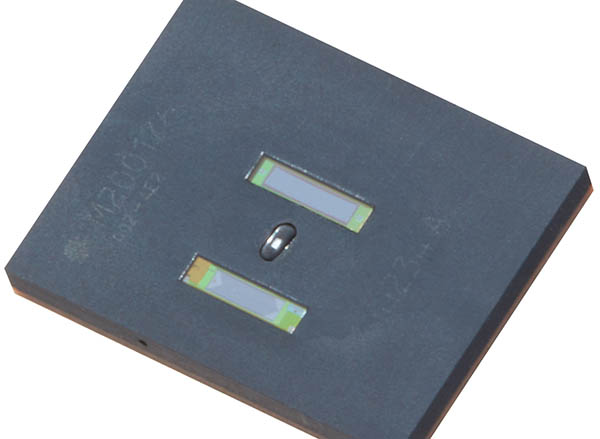

…offers comes in multiple sizes and is designed for precision in motion-control applications. Source: Celera Motion The Field Calibration IncOder is available in Mini and Midi IncOder sizes (37 to 300 mm, or 1.4 to 11.8 in.). Each sensor is fully configurable in terms of mounting format, connection/cable, supply voltage, and single turn and multiturn outputs, said Celera Motion. The new offering also includes extended and digital protocol options, including BiSS-C, SSI, SPI, ABZ and Asynchronous serial outputs. More information about the Field Calibration IncOder is available from Celera Motion's sales team. About Celera Motion Celera Motion said it is…

Found in Robotics News & Content, with a score of 13.64

…advanced industrial markets. The Bedford, Mass.-based company said its precision encoders, motors, and customized mechatronic systems can help customers solve challenging motion-control problems. Novanta Inc., which counts Celera Motion as a business unit, said it has deep proprietary expertise in photonics, vision, and precision motion technologies. The company recently partnered with MassRobotics to help robotics startups in Massachusetts. Aura compensates for eccentricity Aura solves the largest source of angular error, eccentricity, which is caused by off-center scale mounting and bearing runout, claimed Celera Motion. Robotics developers often use two encoders to compensate for the error, increasing cost and power consumption.…

Found in Robotics News & Content, with a score of 13.57

…empowers aerospace MROs with an unparalleled tool that enhances precision, reduces downtime, and increases overall operational efficiency,” he asserted. “A recently installed system proved successful. After I provided training to the customer, they were able to introduce 40 unique part models to the production system easily.” Automating aerospace blade repair Acme Manufacturing said Robotic Auto Path Generation can simplify the robotic programming process and is suitable for high-mix and low-volume manufacturing. The company added that its system is three to four times faster than traditional CNC grinding or manual finishing. Acme automates different processes within aerospace maintenance, repair, and operations.…

Found in Robotics News & Content, with a score of 13.49

…directly into the actuator’s aluminum carrier. The rack offers precision tooth forms identical to the static belt it replaces and is molded from an equally rugged polyurethane - with a 50 Shore D hardness and minimum 4,500 psi tensile strength. The design now allows integrators to splice ServoBelt sections just as they would with a traditional rack-and-pinion, using a simple tool similar to a tooth rack. Bell-Everman said it also offers significantly more resistance to tear-out forces than the earlier design. The latest generation of ServoBelt includes the new molded belt trays, along with QR codes to take personnel directly…

Found in Robotics News & Content, with a score of 13.38

…Adapts to varied box sizes within mixed pallets, maintaining precision and consistency. Each function of the VPick suite incorporates slipsheet and empty pallet detection, comprehensive fault troubleshooting and variable pick tool alignment, all of which are designed to support high levels of picking accuracy and operational reliability. “These products are crafted to tackle the hurdles encountered in contemporary warehousing and logistics industries, which are in need of automation solutions that are both efficient and dependable,” said Bob Berry, president & CEO of Liberty Robotics. “We are excited to roll out these new products to industry.” VPack for packaging options VPack…

Found in Robotics News & Content, with a score of 13.34

…2019, and it expects particpants to help it enhance precision technology in agriculture and construction equipment. “This year's group shows the importance of connecting with the startup community across a broad range of applications and technologies,” stated Julian Sanchez, director of emerging technology at John Deere. “These connections help John Deere better understand opportunities to advance precision technology in agriculture and construction.” Deere & Co. said its agricultural, turf, construction, and forestry equipment includes the John Deere Autonomous 8R Tractor, See & Spray, and E-Power Backhoe. At this year's CES, it announced its ExactShot fertilizer robot. The Moline, Ill.-based company…

Found in Robotics News & Content, with a score of 13.34

…product line designed specifically for surgical robotics and other high-precision applications,” said Facundo Lay, motors and mechatronics product manager at Celera Motion. “This groundbreaking series offers an unmatched combination of raw power, exceptional smoothness, and integration flexibility, setting a new standard for excellence in the precision-motion field. With Omni+, manufacturers can attain smoother, more accurate movements with less noise and vibration, all while optimizing space and simplifying their design.” Designed with customers’ needs in mind, this product line offers a range of axial lengths and winding options, providing the flexibility to achieve optimal system integration effortlessly, the Bedford, Mass-based company…