Editors’ Picks

Found in Robotics News & Content, with a score of 2.25

…effective signal propagation in the presence of walls, floors, inventory and RF interference. This diagram shows the scale of the challenge, identifying the wireless systems co-existing in the operating environment. Shown here, teal dots represent customers with Bluetooth-enabled mobile devices entering the facility. Dark blue dots indicate IoT-enabled point-of-sale systems. Orange dots denote IoT systems that track stock on shelves. And yellow dots represent IoT-connected office systems. Image courtesy of Rigado. “Most IoT applications are greenfield markets—meaning they target new use cases and immature markets that aren’t well understood,” says Mark Chung, CEO and co-founder of Verdigris Technologies. “When entering…

Found in Robotics News & Content, with a score of 2.25

…to delay inducting orders onto the AMRs by completing inventory replenishment tasks first thing in the morning, which led to greater productivity later in the shift, said Matt Fitzgerald, director of product management at 6 River Systems. “The time spent in replenishment led to efficiencies in the order picking process, allowing teams to complete picking work two hours earlier, despite the later start,” he said. Multiple systems require integration Many end user organizations integrate mobile robot fleets with additional systems to gain efficiencies. Most assistive-pick robots need to communicate with a WMS to obtain order data. Meanwhile other sites implement…

Found in Robotics News & Content, with a score of 2.24

…and performing 3D image analysis to create a complete inventory data set comprising every location. Dexory also measures environmental conditions, including temperature, brightness, and humidity. “All this information allows DexoryView - which is the platform that gives and generates all these insights - to create these learnings over time and to inform whoever is running the warehouse either how to optimize things or flag any kind of discrepancies, flag any kind of issues,” Danescu said. “You can start using some of the more advanced AI features to allow you to better organize the way you store goods in the warehouse.”…

Found in Robotics News & Content, with a score of 2.23

…to deliver lineside supplies on a just-in-time basis. When inventory on a conveyor reaches a predefined level, sensors alert the robot’s fleet control software to dispatch the tugger to refill the supply. Once the tugger arrives at the consumption point, the software notifies the automatic trailers to deliver materials to the conveyor and load empty containers back onto the trailers via their own powered conveyor system. Once the exchange is complete, the software dispatches the vehicle back to the pickup point. Automatic trailers and conveyors then exchange empty containers for full containers, and the autonomous tugger is sent to a…

Found in Robotics News & Content, with a score of 2.23

…detection and obstacle avoidance in AMRs and drones. The ICU-2021 can also be used in applications such as shelf inventory monitoring.

Found in Robotics News & Content, with a score of 2.23

…higher places. Pro: Automation can helps minimize errors in inventory management, thereby improving order fulfillment. As is the case with most technology, the exact system that works best for your business will depend on several factors such as the future plans for your business and your initial budget. Whereas manual systems work just fine for relatively small businesses that work with dynamic process handling, robots and automation are great for businesses that deal with many repetitive tasks and larger volumes of materials. Four ways to optimize material handling For businesses wanting to optimize their material handling processes, the following steps…

Found in Robotics News & Content, with a score of 2.21

…its technologies elevate the shopping experience, track and manage inventory, as well as improve supply chain efficiency and patient care. The company uses the same rugged hardware for its MV smart cameras and fixed industrial scanners. Both use Zebra Aurora, a unified software platform that the company said is easy to set up, deploy, and run. Zebra claimed that its machine vision can help reduce defects as well as validate assembly and tracking information to improve productivity and quality. “Zebra Aurora is focused on entry-level and midlevel machine vision challenges, while Adaptive Vision is focused on high-end customers,” Montanari told…

Found in Robotics News & Content, with a score of 2.16

…some kind of mobile or handheld system, either for inventory management or manual data entry. According to surveys by Renovotec, around 70% of the industry currently relies on Windows-based mobile operating systems for their devices - despite the fact that support for these systems is due to end in January 2020. With many of these devices now outdated and open to security risks, now may be the time to switch to an Android based system, such as those offered by Honeywell. These devices can be just as durable, and will benefit from an increase in speed and functionality. The Android…

Found in Robotics News & Content, with a score of 2.16

…warehouse is gaining steam. The driver can load non-committed inventory into delivery trucks, allowing drivers to upsell during the delivery process. The driver can bring items the consumer has ordered in the past or might need or want, processing a potential additional order in person. This has started for food and grocery as well as with household commodities and even pharmaceuticals. 8. Smart Technology and Sensors In addition to wanting visibility at each point in the fulfillment and delivery process, customers want to track temperature sensitive items. This way the pharmaceutical company, frozen foods or spirits manufacturer will know the…

Found in Robotics News & Content, with a score of 2.15

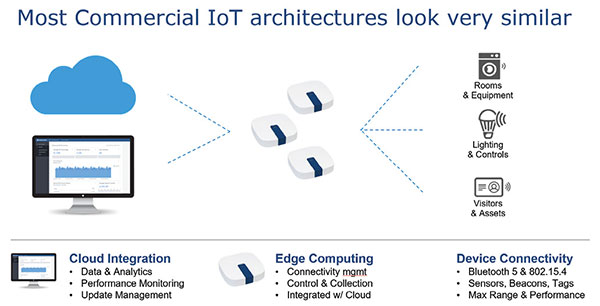

…improper handling; and ensures compliance with all storage and inventory management requirements. Let Tapestry Help Your Organization Tap the Power of the IoT The possibilities of connecting billions of people and “things” through the cloud and networks – with unprecedented processing power, storage capacity and access to knowledge – are virtually limitless. These possibilities are multiplied by emerging technologies in fields such as artificial intelligence, robotics, autonomous vehicles, 3-D printing, nanotechnology and quantum computing. However, enterprises must first lay a solid foundation to ensure successful entry into this rapidly evolving landscape. The key benefits are total asset visibility, improved productivity…

Found in Robotics News & Content, with a score of 2.13

…Istanbul-based company provides the ability to track all the inventory and operational processes in its fulfilment centers. OPLOG founder focuses on both software and hardware Founded in 2013, OPLOG has warehouses in Gebze, Dilovasi, and Ankara, Turkey. “OPLOG was a bootstrapped business until recently,” said Halit Develioğlu, founder and CEO of OPLOG. “I've spent 16 years venturing into the intersection of logistics and computer technology.” A lifelong entrepreneur, Develioğlu has been included in the Fortune “40 Under 40.” He told Robotics 24/7 that his goal has been to “provide end-to-end fulfillment services to brands.” “My first company provided software for…

Found in Robotics News & Content, with a score of 2.13

…but also in reducing the risk of damage to inventory, trucks, or to facility assets.” The rise of automated lift trucks Lift truck providers agree that automated vehicles are bound to grow in popularity given the continued challenges. And while warehouse efficiency efforts often focus on automated order-picking systems, goods also need to be handled, staged or stored at the pallet level, which presents opportunities for robotics. “I firmly believe this pandemic will accelerate the adoption of automated lift trucks, as well as many other forms of materials handling automation,” said Brett Wood, president and CEO of Toyota Material Handling…