Editors’ Picks

Found in Robotics News & Content, with a score of 2.21

…white paper we explore the rise of the digital yard and show how technology is enabling significant efficiencies, productivity gains, and cost containment in a world where every penny added to the bottom line positively impacts organizational success. Download Now! Solution Brief: Yard Management System Yards are the intersection between warehouses and transportation, they are a critical linkage in logistics management practices and have a significant impact on the overall efficiency of the supply chain. Download Now! More PINC Resources

Found in Robotics News & Content, with a score of 2.19

…FANUC said its new LiS-B series linear motors have set new standards for acceleration, precision and speed, delivering high gain and rigidity with excellent path accuracy. Unlike conventional drives, these motors work without any force transmission mechanisms, making machine design and maintenance easier (no ball screws, no backlash), the company said. The linear design enables rigid long-stroke axes, increased thrust force and multi-head configurations by arranging multiple coil sliders on a single magnet track. The company will also have a Panel I Industrial PC demo.

Found in Robotics News & Content, with a score of 2.18

…& Robotics Indxx ETF helps Korean investors and innovators gain access to the rapidly growing AI and robotics market. The AI robot market is forecasted to witness a CAGR [compound annual growth rate] of 22.3% between 2023 and 2030, with its value expected to reach $44.6 billion by 2030. Key growth drivers of this market are the ever-increasing integration of automation across a wide range of industries, advancements in machine learning algorithms, and ascending consumer demand for personalized experiences. Moreover, the swift expansion of this industry is being propelled by strides made in sensor technology, reductions in hardware costs, and…

Found in Robotics News & Content, with a score of 2.18

…systems manager for Intelligrated, says robots will make gradual gains in these environments by targeting specific elements of the picking process. “I see robots offering value by providing mobility in the spaces between tasks,” Wohlrab says. “This will enhance the amount of tasks a picker can do within a work zone, where he or she might work alongside a mobile, collaborative robot.” For operations that cannot justify a robotic goods-to-person solution or automated storage and retrieval system (AS/RS), this kind of mobile robot could support picking, replenishment and packing without requiring major adjustments to existing processes or infrastructure. That said,…

Found in Robotics News & Content, with a score of 2.16

…robots with synthetic data generation (via Isaac Replicator), and gain operational efficiencies before physically implementing them in warehouses. This helps the e-commerce giant fulfill thousands of orders in a cost- and time-efficient manner [see video below]. Telexistence has deployed beverage restocking robots across 300 convenience stores in Japan. Deutsche Bahn is training AI models to handle very important but unexpected corner cases that happen rarely in the real world — like luggage falling on a train track, to improve safety. Festo uses Isaac Cortex to simplify programming for cobots and transfer simulated skills to the physical robots. Fraunhofer is developing…

Found in Robotics News & Content, with a score of 2.14

…precision. Still others, he says, go with automation to gain optimum control and discipline. Bar codes (pictured) or even radio beacons (in the future) automate the product identification process, ensuring accuracy of returns handling. Source: OPEX The move to automation Control and discipline Control and discipline are what Schechter said are central to success in handling the entire returns process. Quite simply, they are the two key qualities that automation brings to the processing center while gaining critical feedback on inventory quality. “Returns are all about faster,” said Honeywell Intelligrated's Rowland. “How do you decide the disposition of an item…

Found in Robotics News & Content, with a score of 2.13

…Manufacturers are increasingly investing in research and development to gain insights into consumer behaviors, quality improvements, alternative manufacturing materials and processes, sustainable manufacturing infrastructure, and in-house employee training needs. As Industry 4.0 takes over the manufacturing space, companies must implement solutions that promise to increase the competitiveness of the brands on a global scale. These companies should adopt customer-centric solutions that lower production costs. That way, they can grow their customer bases, venture into new products, and enhance product quality. Shortage of skilled labor The manufacturing business is labor-intensive and targets highly-skilled individuals. Everything from production to operations and maintenance…

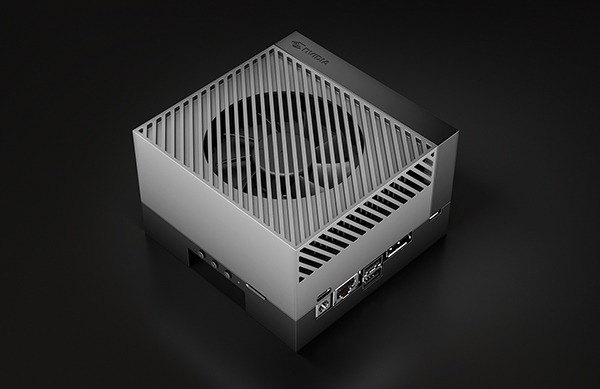

Found in Robotics News & Content, with a score of 2.13

…pretrained models from the NVIDIA NGC catalog. They also gain access to the latest frameworks and tools for application development and optimization such as NVIDIA Isaac on Omniverse, Clara for healthcare, Metropolis, and the TAO Toolkit. “AI model development is a time-consuming process,” Talla said. “NVIDIA's application frameworks include easy-to-use libraries that accelerate runtime applications.” These tools can reduce time and cost for production-quality AI deployments, allowing developers to access the largest, most complex models needed to solve robotics and edge AI challenges in 3D perception, natural language understanding, multisensor fusion, and more, NVIDIA said. NVIDIA touts ecosystem support, customer…

Found in Robotics News & Content, with a score of 2.12

…bottlenecks upstream or downstream, he said. “If you make gains by automating in one area, but what exists is downstream remains manual, all you are really doing is moving the bottleneck,” said Nieves. “That is why fulfillment centers are going to turn to integrated solutions that can expand the benefits of automation out from the center, from something like an ASRS. That is where the value increasingly will come from—in deploying flexible robotics automation out from the middle, so you can have efficiencies not just in one area of your fulfillment center, but from one end of the building to…

Found in Robotics News & Content, with a score of 2.11

…Building denser pallets, for instance, can help save transportation costs. Stable pallets that don’t fall over is another small gain. Building pallets that allow for orderly unloading at retailers increases accuracy and speed, as does the reduction in mis-picks when machines take the place of humans. From Campbell’s perspective, collaborative palletizers are the way of the future. “They are going into environments that traditional robots couldn’t,” he said. “We’re breaking new ground with these collaborative efforts, entering markets that couldn’t consider this type of automation in the past.” About the author Amanda Loudin is a contributing editor at Logistics Management,…

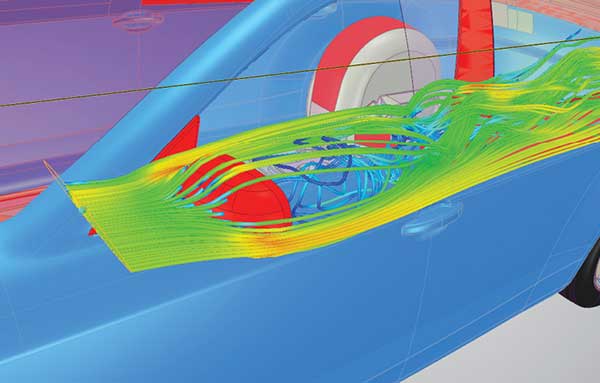

Found in Robotics News & Content, with a score of 2.11

…when working with large models. These are exponential graphics gains, not linear. That’s a big change.” This level of improved graphics in SolidWorks currently requires RTX technology found in newer NVIDIA GPUs. For many users, this change is an inflection point. “If you were using an entry-level GPU before, maybe now is the time to move up,” says Rink. Pervasive Simulation Since the dawn of computer-aided engineering, the workflow required product design models be sent to a simulation expert. These experts were the ones with the more powerful workstations—or high-performance clusters. At most companies, the analysis review was a bottleneck…

Found in Robotics News & Content, with a score of 2.08

…(No. 10) and SICK (No. 11) posted substantial double-digit gains, year-over-year,” Krebs adds. Other companies rounding out VDC’s list of top AIDC vendors this year were Honeywell (No. 2), Datalogic (No. 3), Cognex (No. 5), Toshiba TEC (No. 6), Denso Wave (No. 7) and Panasonic (No. 8). These companies’ year-over-year revenue comparison was a mixed bag, with some posting increases as high as 37.8% over 2019 (Fujian Newland) and others reporting decreases of up to 23% (Panasonic). These numbers include only hardware revenues for handheld rugged mobile computers, vehicle mounted computers, handheld and stationary bar code scanners, and thermal label…