Editors’ Picks

Found in Robotics News & Content, with a score of 23.25

…Radel polyphenylsulfone (PPSU) to e-Xstream’s latest release (2019.0) of Digimat-Additive Manufacturing (AM) software. These products complement the neat KetaSpire PEEK AM filament already available for simulation on e-Xstream engineering’s Digimat-AM platform. “Our growing range of AM filaments underscores Solvay’s determination to establish itself as an industry leader in this rapidly evolving market,” says Christophe Schramm, Additive Manufacturing business manager in the company’s Specialty Polymers global business unit. “DigimatAM allows customers to simulate the printing process and successfully predict the thermomechanical behaviour of 3D-printed designs in order to ‘print right the first time’.” These new materials will benefit from e-Xstream engineering’s…

Found in Robotics News & Content, with a score of 28.13

EWI, an engineering and technology provider of advanced manufacturing in North America, has selected Granta Design's GRANTA MI software to better coordinate its additive manufacturing (AM) work across multiple AM platforms. The software system is currently being deployed. GRANTA MI is made for enterprise materials information management. EWI’s engineering services aim to help companies identify, develop, and implement the best options for their specific applications. Defining a strategy to capture and characterize material information across different AM platforms is currently a challenge. Every AM machine monitors different metrics, and exports data differently. EWI is meeting this challenge by defining the…

Found in Robotics News & Content, with a score of 26.18

…offers well-regarded coursework for students and professionals related to additive manufacturing. Last year, MIT announced it was forming a new industry consortium to focus on additive manufacturing—the Center for Additive and Digital Advanced Production Technologies (ADAPT)—to focus on expanding the use of AM in industry through new research, education platforms, and more academic-industry partnerships. According to ADAPT’s program manager, Haden Quinlan, the idea for the consortium was first floated back in 2016. “There was a level of industrial excitement at that time, and today, that made additive manufacturing even more relevant than ever,” Quinlan says. “At the same time, we…

Found in Robotics News & Content, with a score of 33.45

…for creating, integrating and validating custom engineered materials for additive manufacturing. “Jabil is taking advantage of its rich history in materials science innovation to advance the entire additive manufacturing market forward and produce custom materials in weeks—not months,” says John Dulchinos, vice president of digital manufacturing, Jabil. “Our ability to integrate new engineered materials into our ecosystem of 3D printers and rigorous processes will transform a new generation of additive manufacturing applications, including those for heavily regulated industries, such as aerospace, automotive, industrial and healthcare.” Driving Adoption with Integrated Materials, Processes and Machines (MPM) Jabil will evaluate, qualify and validate…

Found in Robotics News & Content, with a score of 30.78

The software manufacturer CoreTechnologie (CT) presents its new 4D_Additive Manufacturing Software Suite. The German-French company has introduced a software suite to prepare CAD models for all major 3D printing methods. With 4D_Additive CAD data of all current systems such as Catia, NX, Solidworks, Creo, STEP or JT is read by precise native interfaces and processed as exact B-Rep geometry including all contained product manufacturing information (PMI). This enables ability to analyze, repair and prepare the 3D models with highest precision and according to CAD engineering standard. With conventional 3D printing software, CAD models are usually triangulated, i.e., converted to STL…

Found in Robotics News & Content, with a score of 35.00

…The Optomec LENS family offers a full range of additive manufacturing solutions for creating, enhancing and repairing metal components using high-powered lasers to build structures layer by layer directly from powdered metals, alloys, ceramics or composites. “The agreement enables Phillips to continue to provide the best additive manufacturing solutions to maintain the readiness of the military and advance the research and development of new innovations and ideas throughout our government,” says Mr. John Harrison, vice president of Phillips Federal. “We’ve seen an increase in the demand for additive manufacturing solutions and our partnership with Optomec will allow us to continue…

Found in Robotics News & Content, with a score of 20.79

…is a prime example of how our unique multi-material additive manufacturing technology can rapidly accelerate development cycles and time-to-market,” says Amit Dror, CEO of Nano Dimension. “We have been working with HENDSOLT since we initiated our beta program two years ago and are excited to see how they are continuing to leverage our multi-material additive manufacturing technology into new application areas to further increase efficiencies across its development process.” “With its novel multi-material capability, the DragonFly Pro is bringing rapid prototyping and agile workflow possibilities to electrical engineers and companies from many industries,” says Sven Dengel, CEO of Phytec New…

Found in Robotics News & Content, with a score of 11.89

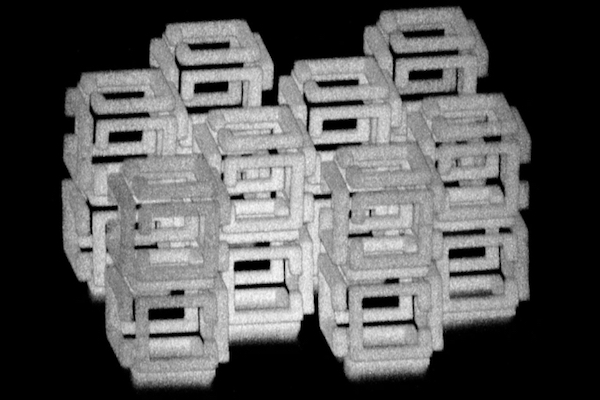

Projects that leverage additive manufacturing and 3D printing to create really big objects have gotten a lot of attention. Massive robotic printing systems have been developed to create everything from cars to entire buildings. Those big 3D printers are impressive, but printing very small objects is actually a lot harder. Getting high resolution at smaller scales is difficult, and there are limits to just how detailed you can get once you move into nanoscale territory. Researchers at MIT appear to have found a way around this problem by printing small objects and then shrinking them to even tinier sizes after…

Found in Robotics News & Content, with a score of 24.41

…the U.S. Navy sees positive results as it tests additive manufacturing for ship-building applications. Back in October, Naval Sea Systems Command announced it had approved a 3D-printed metal drain strainer for use on the aircraft carrier the Harry S. Truman. The prototype part was installed in the carrier’s steam system as part of a one-year trial. The strainer was originally a cast part that required a nine-month lead time to produce. The printed piece was created by Huntington Ingalls Industries and Newport News Shipbilding, which has been working on on its own maritime printing projects. The printed part took just…

Found in Robotics News & Content, with a score of 12.60

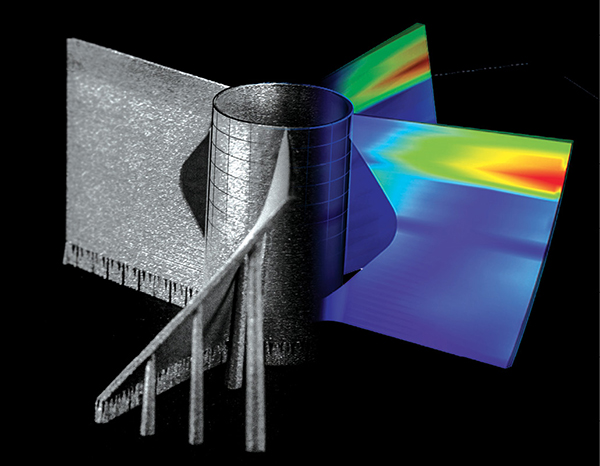

As more companies use additive manufacturing (AM) processes to create end-use metal parts (not just prototypes), quality and scrappage issues associated with AM have become a bigger issue. Many 3D printing technologies have demonstrated high degrees of variability regarding consistent parts creation, and because design for AM skills are often in short supply at most companies, there is great trial and error involved in creating usable parts. That has resulted in a high percentage of scrap and wasted materials. To reduce waste and improve part quality, end users need a way to virtually test builds before creating physical parts. An…

Found in Robotics News & Content, with a score of 21.69

One by one, the barriers to additive manufacturing (AM) are being knocked down as a continuing spate of offerings address cost, performance and ease-of-use constraints that have relegated the technology to a supporting role, primarily for prototyping and limited production-run applications. Now, CEAD Group is doing its part to advance the AM value proposition with the official launch of its CFAM Prime 3D printer, which brings continuous fiber printing for composite applications to an industrial scale. The company, which was formed out of Leapfrog, another Dutch company specializing in desktop 3D printers, is targeting its printer at companies in the…

Found in Robotics News & Content, with a score of 17.58

…gave the media a peak inside its new Advanced Manufacturing Center, a $45 million facility in Redford that will use 3D printing, virtual reality, simulation and collaborative robots to create new innovations in vehicle production. “More than 100 years ago, Ford created the moving assembly line, forever changing how vehicles would be mass-produced,” said Joe Hinrichs, Ford’s president of Global Operations. “Today, we are reinventing tomorrow’s assembly line — tapping technologies once only dreamed of on the big screen — to increase our manufacturing efficiency and quality.” The 3D printing in the facility includes the additive manufacturing of brake parts…