Editors’ Picks

Found in Robotics News & Content, with a score of 10.57

…Fellowship program supports the AIM Higher Consortium, a Defense Manufacturing Community. “The ARM Institute is proud to support Defense Manufacturing Communities,” stated Matt Fischer, senior new business development manager at the ARM Institute. “These regional clusters are integral for strengthening U.S. defense manufacturing capabilities, and our fellowship program in partnership with the AIM Higher Consortium is critical to advancing much-needed robotics and AI solutions.” The AIM Higher Consortium supports an industrial production ecosystem that combines advanced metals and materials with Industry 4.0 technologies such as robotics, artificial intelligence, and additive manufacturing (AM). As ARM Institute Fellows, Clark and Ravasio will…

Found in Robotics News & Content, with a score of 10.53

…Rolleri Robotic collaborative robots for easier welding operations in manufacturing. “We developed xCognition to provide a synthetic brain for commercial industrial robots and cobots used in a range of applications, from consumer and PCB assembly to industrial manufacturing for the automotive and aerospace sectors,” said Massimiliano Moruzzi, CEO of Xaba, in a press release. “Our goal is to make it easier and much more efficient for anyone to adopt robotics for assembly, welding, and drilling by significantly reducing the time required to calibrate, program, and supervise robots,” he added. “This partnership with Rolleri is an important step in enabling us…

Found in Robotics News & Content, with a score of 10.47

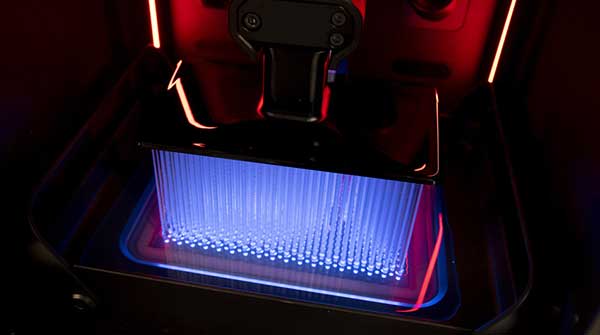

Origin, developer of an open platform for additive mass manufacturing, is collaborating with Beth Israel Deaconess Medical Center (BIDMC) to find a solution for manufacturing COVID-19 test swabs. Over the last 2 weeks, Origin has quickly shifted its resources from being a 3D printer manufacturer to become a medical device manufacturer and has started production to address the shortage of COVID-19 test kit supplies. BIDMC, an academic medical center affiliated with Harvard Medical School, selected Origin's 3D-printed test swab to be part of a clinical trial to evaluate it for efficacy and safety. Origin's 3D-printed swab passed a rigorous initial…

Found in Robotics News & Content, with a score of 10.41

…the growing use of advanced technologies for eyewear marketing, manufacturing, and distribution. Specifically, industry applications of robotics and artificial intelligence can play a substantial role in boosting sales and the overall customer experience. This paints an optimistic picture for the global eyewear market in the coming years. Robots and automation modernize supply chains Robotics and automation have been instrumental in modernizing the supply chain, starting with design and manufacturing. For example, Materialise NV and Ditto have partnered to introduce 3D printing to the eyewear industry. With a focus on developing end-to-end platforms, this collaboration and others seek to use additive…

Found in Robotics News & Content, with a score of 10.32

…technology is increasingly being eyed as a complement to additive manufacturing (AM) with the outcome being new workflows that turn out game-changing products. Generative design tools, which include topology optimization and other artificial intelligence-based modeling techniques, burst on the scene these last few years as less expensive and more accessible computing power gives way to new algorithmic-driven design approaches. These design tools provide a whole new level of design freedom by automating the ideation of hundreds of possibilities based off of specified parameters and constraints. The approach helps engineering teams zero in on parts and products that are fully optimized…

Found in Robotics News & Content, with a score of 10.32

…Group invests in startups that specialize in automation, robotics, additive manufacturing, and AI. The Swiss holding focuses on seed and Series A equity investments. It supports young companies with a technology park and a team of experts in business development, finance, human resources, IT, marketing, and communications. Capital Risque Fribourg SA is an innovation capital fund financed by the canton of Fribourg, Banque Cantonale de Fribourg, Groupe E, and the Pension Fund of the Canton of Fribourg. Swiss cantons are similar to U.S. states. Capital Risk Fribourg said it invests in early-stage companies that create jobs in the canton of…

Found in Robotics News & Content, with a score of 10.22

…and infrastructure health monitoring. Dive said it uses large-format additive manufacturing (LFAM) techniques and a novel system architecture to rapidly produce the DIVE-LD at a fraction of the time and cost of existing AUVs. Unmanned offerings to provide ocean intelligence Anduril and Dive said the integration of the next DIVE-LD iteration with the Lattice OS autonomy software “will further disrupt this segment of the market.” “We built Dive to make undersea exploration safer, smarter, and cheaper and to offer customers the highest level of customization,” said Bill Lebo, co-founder and CEO of Dive Technologies. “With Anduril, we will rapidly scale…

Found in Robotics News & Content, with a score of 10.19

…data management expertise) is critical as is experience with additive manufacturing, which can provide a clear advantage for producing short runs of customized products. “Businesses will need to invest in the composite materials to meet their item requirements and the 3D printing infrastructure needed to produce custom items at the desired production scale,” Sappin says. Canoo’s modular “skateboard” is a universal underbody upon which many different vehicle “cabins” can sit. Image Courtesy of Dassault Systèmes The 3DEXPERIENCE platform also delivers capabilities that foster personalization in product design, he adds. The platform’s extensive simulation capabilities, including the ability to explore electromagnetic…

Found in Robotics News & Content, with a score of 9.81

Additive manufacturing companies have been active during the worldwide pandemic and shutdown, helping health care providers and other companies address supply chain shortages. Digital Engineering spoke to Jonah Myerberg, co-founder and CTO at Desktop Metal, about the company’s activities and experiences during the COVID-19 shutdown. DE: Desktop Metal has been involved in rapidly developing and producing a new COVID-19 nasal test swab. Can you tell me about that project? Jonah Myerberg: Although swabs are not made of metal, this was an initiative we identified right away where we could help. This wasn’t something we could print out metal or even…

Found in Robotics News & Content, with a score of 9.71

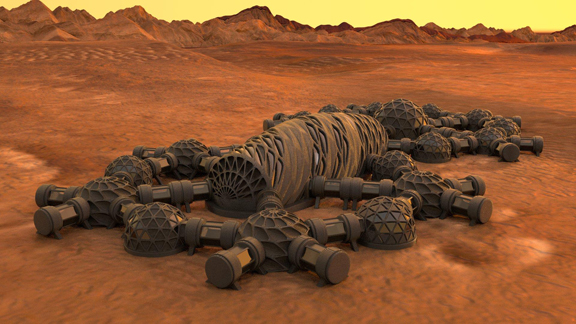

…post explaining the project with NASA, Raymond Deplazes, Autodesk's Manufacturing & Research PR, writes, “NASA’s Swamp Works lab is experimenting with 3D-printing habitable structures using a process called robotic extrusion, and a composite material made up of loose sediment (soil, dust, broken rock, etc.) and recycled plastic. The sediment, known as regolith, can be widely found on Earth, other planets, the moon, and even asteroids ... Based on NASA specifications, Autodesk’s Advanced Consulting team designed the barrier using tools such as Fusion 360 and PowerMill to comply with structural as well as robotic extrusion requirements while achieving significant weight reduction.…

Found in Robotics News & Content, with a score of 9.53

…But this isn’t necessarily a new use case of additive manufacturing (AM). Over the course of the technology’s adoption, 3D printing hardware and materials have gained traction in regions of earthquakes, conflict and a variety of natural disasters. A carry-on printer Eric James, executive director of Field Ready, occasionally flew with a 3D printer as part of his allowable carry-on luggage. Over the years, he had to figure out how to fit a 3D printer into a commercial jet’s overhead bin and how to operate it in war-torn, disaster-hit regions where electricity and high-speed internet connection are not always guaranteed.…

Found in Robotics News & Content, with a score of 9.47

…Ph.D. student Tae-Ho Kim, and a team in SFU's Additive Manufacturing Lab have researched how the intracies of origami and bioinspired motion can help robots perform diagnostic procedures. They have replaced the traditional blood-pressure check by replicating the folding mechanisms of the leech in their design of 3D-printable origami sensors. The leech-inspired origami (LIO) sensors can be integrated onto the fingertips of a humanoid sensing robot. The research was published in the journal npj Flexible Electronics from Nature Publishing Group. “Our origami-inspired dry electrode has unique characteristics such as suction for grasping and foldability inspired by nature,” said Kim, a…