Editors’ Picks

Found in Robotics News & Content, with a score of 28.27

…Robots, a developer of 7-axis industrial cobot solutions for machine tending, material handling, dispensing, and various other applications, has established a U.S.-based team focused on sales and support. Kassow Robots is part of Bosch Rexroth, which has been its majority owner since 2022. The company has named Jim Adamski, Collin Ayres, and Chris Hapsias to support Kassow Robots’ sales partners, system integrators, and distributors in the United States. Adamski and Ayres serve as regional channel partner managers while Hapsias is a technical support engineer. “This team will allow us to work closely with our system integrators and distributors in the…

Found in Robotics News & Content, with a score of 28.01

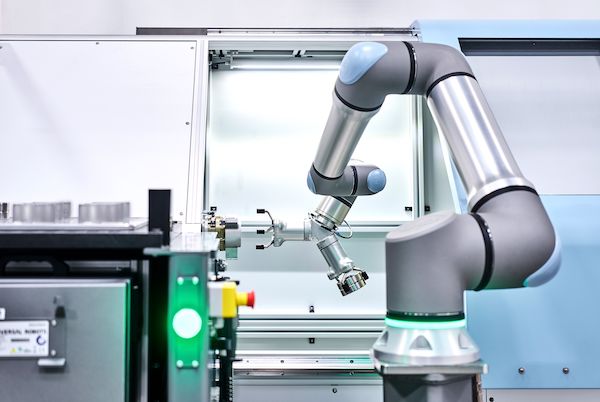

…loads. This makes UR30 ideal for several applications, including machine tending, material handling, and high torque screw driving. “The unique combination of being shorter and smaller, but still being able to handle heavier loads has unlocked a number of applications even our current portfolio of robots with long reach didn’t serve well,” said Anders Billesø Beck, Universal Robots’ vice president, Strategy & Innovation, at the press conference announcing the new offering. For machine tending, the high payload brings new possibilities as it allows the cobot to use multiple grippers at the same time. This means it can remove finished parts…

Found in Robotics News & Content, with a score of 27.42

…robots are also useful for hard-to-staff tasks such as machine tending, dispensing, labeling, and screwdriving. “Our application diversity at this year’s Automate speaks volumes,” said Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots (UR). “Attendees visiting us and our partners at the show will have no issue finding a UR cobot automating the task they’re looking for.” Welding is a hot application for cobots Coming out of a record revenue quarter, Universal Robots said it is experiencing broad-based growth from many different segments including welding, an application area that grew 300% in 2021 in comparison…

Found in Robotics News & Content, with a score of 27.36

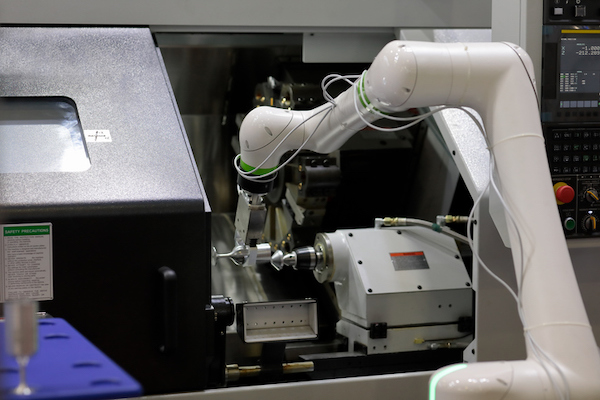

US-based manufacturer of CNC machines and industrial robotics Tormach recently introduced its 1500MX CNC for milling. Tormach said its 1500MX marks a significant leap forward in power, precision, and affordability within their CNC machining portfolio. The 1500MX is optimized to pair with Tormach’s ZA6 industrial robot arm for light machine tending capabilities. Tormach’s new 1500MX is a 3-axis, servo-driven mill on linear rails with an epoxy granite frame. The company said its 1500MX combines professional-grade capabilities with easy-to-use compact versatility, making it ideal for both commercial enterprises and garage-based enthusiasts. “For the past 20 years, Tormach has helped our customers…

Found in Robotics News & Content, with a score of 27.01

…has nearly 500 employees worldwide. It provides 3D cameras, machine vision software, and deep learning algorithms. It also offers motion-planning technology, programming models, and consulting and training services. The company said manufacturing and logistics customers can use its systems for mixed-order picking, palletizing and depalletizing, and machine tending. It claimed that its systems can attain picking speeds of 1,200 pieces per hour. In July, MechMind released its new Mech-Eye Nano, a small camera than can be mounted on robot arms for pick-and-place and other operations in manufacturing. It has worked with Siemens on using simulation to develop its products. Mech-Mind…

Found in Robotics News & Content, with a score of 26.50

…what might this look like as a practical example? Machine tending as a model If we look at the now-mature robot application of CNC machine tending, we see that it’s presently addressed with a general-purpose, six degree-of-freedom (DoF) arm that is not optimized for any specific CNC machine. It involves integration, personnel training, custom tooling, and myriad other friction points or barriers to entry. Several options are available, including choices of robot make, size, and internal or external integration partner. This and other steps can quickly add up to a custom project, improving productivity but not necessarily optimization. There is…

Found in Robotics News & Content, with a score of 25.79

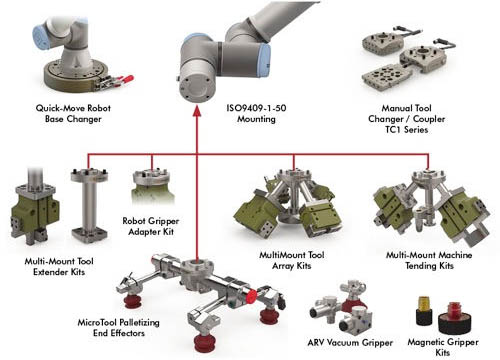

…The tools can be used to complete gripping, palletizing, machine tending, tool changing, and tool-extension applications. Destaco, a Dover Corp. company, said it is a leader in the design and manufacture of high-performance automation, workholding, and remote-handling systems. The company serves customers in a variety of end-markets, including the automotive, life sciences, consumer packaged goods, aerospace, industrial and nuclear sectors. “Small payload robots are commonly found in larger industrial manufacturing facilities, but the low-cost entry into robotic automation has recently resulted in significant growth in their use across small, light industrial, and commercial shops,” said Gary Labadie, global product director…

Found in Robotics News & Content, with a score of 25.26

…The company focuses on material handling, automated assembly, and machine vision applications “that augment human labor and fulfill the promise of Industry 4.0.” Futura Automation has offices and representatives across the U.S. and in Queretaro, Mexico. Futura Automation will be READY's stocking distributor for states including Arizona, California, Idaho, Iowa, Kansas, Louisiana, Minnesota, Missouri, Montana, Nevada, North Dakota, Oklahoma, Oregon, South Dakota, Texas, and Washington. “Futura Automation provides innovative solutions for tough manufacturing problems. Our team is focused on helping our customers compete in global markets and allow reshoring of production using automation tools such as robots, machine vision and…

Found in Robotics News & Content, with a score of 25.17

…as laboratory automation or stock replenishment. Reacher designed for machine tending, palletizing, and bin picking The Reacher line includes seven new cobot models - RE 07, RE 09, RE 13, RE 16, RE 21, RE 30, and RE 30L - which can handle loads ranging from 15 to 66 pounds. In addition to the cobots’ improved design, Rethink said their hardware can deliver increased precision, speed, and durability, enhancing their capabilities for industrial use. Reacher cobot arms are supported by an IP65 rating for use in wet and dusty environments. Reacher cobots offer a precision within 0.03 millimeter pose repeatability.…

Found in Robotics News & Content, with a score of 25.12

Automating machine loading traditionally means integrating conveyors, bowl feeders, custom trays, shaker tables, or various other components and processes. These approaches can lead to a range of obstacles, including complex programming and setup, poorly used manpower, inefficient machine utilization, and decreased output, according to Universal Robots A/S. Universal Robots said its ActiNav product combines intelligent vision and sensor software with autonomous motion control of collaborative robot arms in one Application Kit. The Odense, Denmark-based company claimed that ActiNav can solve the random bin-picking challenge in machine tending applications. To give manufacturers an opportunity to experience ActiNav firsthand, Universal Robots plans…

Found in Robotics News & Content, with a score of 24.96

…system and offers two different base options: standard and machine tool bases. ARIA’s Standard Base option is designed for various industry applications where flexibility and mobility are a must. The machine tool base is designed for tending CNC mill, lathe and Swiss applications. Both bases are suitable for Mitsubishi Electric collaborative, vertical/articulated and SCARA robots. “ARIA fulfills an immediate need for flexible and cost-effective automation that addresses common industry problems such as labor shortages, productivity challenges, and the need to maintain quality standards,” said David Simak, product manager (service) at Mitsubishi Electric. “ARIA is fully configurable and mobile, making it…

Found in Robotics News & Content, with a score of 24.35

…cell showing collision management ICONICS: supervisory control and data acquisition (SCADA) solutions including remote monitoring and incident management Absolute Machine Tools: automated machine tending, including ICONICS SCADA integration for remote monitoring Mitsubishi Electric Contact Image Censors (CIS): continuous scanning for quality control To learn more, visit Mitsubishi Electric Automation at Booth 1023 at Automate 2022, from June 6 to June 9. More than 20,000 attendees are expected to attend.