Editors’ Picks

Found in Robotics News & Content, with a score of 13.45

…to pick things out of cluttered bins, assemblies, packaging, machine tending, and also to move around larger things.” Its customers span multiple industries including medical, pharmaceutical, automotive, general manufacturing, energy, and warehousing. Right now, CapSen's customer base is still small. Glover said it has less than 10. The nine-year-old company has focused on staying small because the systems it makes can each individually take months to conceptualize and deploy, he explained. But with its presence at Automate and the recent public release of Version 1.0 of its CapSen PiC system, the company said it is now planning on scaling up…

Found in Robotics News & Content, with a score of 19.32

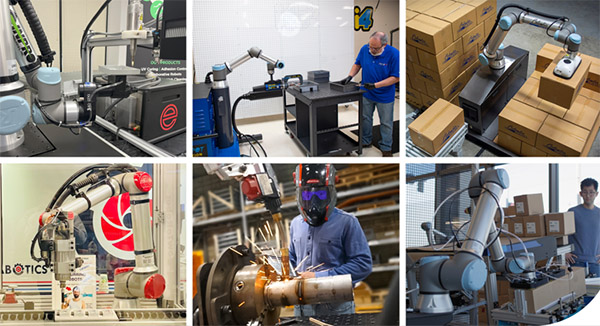

…will show the UR20 at its booth in a machine tending application, loading and unloading heavy workpieces into a machine fixture. Universal Robots collaborated with Pro Spot International for the first spot welding application. Source: Universal Robots New takes on palletizing, case packing Manufacturers looking to verify whether a UR cobot palletizer will work for their applications can now receive a complete project analysis with performance and installation data delivered right in UR’s booth. With MyRobot.cloud, Rocketfarm is launching the first digital twin designed for palletizing with UR cobots. Integrators can now quickly verify customer projects on site. The system…

Found in Robotics News & Content, with a score of 11.93

…viable option for low- to medium-volume orders where insertion machines would not be cost effective, said ABB. The company said its original cobot also offers a significant advantage over repetitive and physically stressful manual insertion of THT components. AMRs to include VSLAM ABB said it has transformed AMRs with the addition of visual simultaneous localization and mapping (VSLAM) technology in collaboration with Swiss-based AI specialist Sevensense. VSLAM enables a mobile robot to “see its environment and make intelligent navigation decisions based on its surroundings, without prior programming or infrastructure,” the company stated. This next-generation AMR technology supports new levels of…

Found in Robotics News & Content, with a score of 38.77

…each step of a task or job. The plug-and-play machines are engineered to work with new or legacy equipment and have the flexibility to perform both simple and complex activities, it said. Productive Robotics’ cloud analytics system streamlines connectivity requirements for nimble data collection and reporting. Installation for the kitted OB7 cobots is simple and quick and can be performed whether an application calls for repetitive part work, tending a CNC machine or manning a lights-out operation. “Cobots augment and enhance a fabricator’s capabilities with precision, repeatability, and tireless performance, freeing employees from tedious, repetitive activities so that they can…

Found in Robotics News & Content, with a score of 29.35

…and repetitive tasks that require long reach, such as machine tending, assembly, quality assurance, or pick-and-place tasks, according to Kassow Robots. The KR1805 has a reach of 1,800 mm and can handle a payload up to 5 kg. Source: Kassow Robots The robot's seventh axis, or “wrist joint,” enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm, said the company. The seventh axis also gives the KR1805 a small footprint of 160 x 160 mm (6.2 x 6.2 in.). This provides “a huge advantage in maneuverability” and an increased range…

Found in Robotics News & Content, with a score of 16.42

…staff works out of a 95,000-sq.-ft. steel fabrication and machine shop. “As manufacturing is coming back to the States, we're getting more orders than we can handle,” said Helfrich, a manufacturing engineer at the company. “We used to build two to three [systems] a month. Now, they want 100 and maybe even 150 a year, so it's quite an increase in production.” The company takes advantage of some semi-automated processes for CNC machining and welding, but it's hoping to invest in a robotic arm or two to help with welding and cutting. Helfrich Brothers Boiler Works, like many small and…

Found in Robotics News & Content, with a score of 15.47

…experts will help manufacturers prototype solutions and demonstrate proofs-of-concept. The Hub will explore solutions in many manufacturing areas, including machine tending, assembly/disassembly, inspection, to name a few. Qualifications This service is available only to small and medium-sized manufacturers in the Southwestern Pennsylvania region, limited to the following 11 counties: Allegheny Armstrong Beaver Butler Cambria Fayette Greene Indiana Lawrence Washington Westmoreland Manufacturers must fit into the small and medium-sized range, defined as having 500 or fewer employees and less than $100M in annual revenue.

Found in Robotics News & Content, with a score of 22.81

…refers to the combination of computer numerical control (CNC) machines with cutting-edge robotics. CNC machines use pre-programmed software to control their movement and operation. Types of CNC robots include Cartesian, cylindrical, and SCARA robots. The potential benefits from such robots include increased efficiency and productivity, improved accuracy and precision, and reduced labor costs. These machines can perform complex tasks with high consistency and accuracy, making them ideal for mass production and high-precision applications. CNC robotics has revolutionized the manufacturing industry, allowing for faster production times, greater precision, and easier changeover of product designs. What is CNC machining? Before we can…

Found in Robotics News & Content, with a score of 14.96

…automation Mobile robots and palletizing Piece picking and perception Machine tending and welding with collaborative robots RAC ’22 included presenters from integrators and end users such as Körber Supply Chain, GXO Logistics, and Toyota North America. Attendees included leading global companies including Ahold Delhaize, Amazon, Cargill, Carrier, Fuji, Garmin, General Mills, HomeGoods, Johnson & Johnson, the Mayo Clinic, and Starbucks. In addition, Aaron Prather, director of the Robotics & Autonomous Systems Program at ASTM International, delivered the keynote address on optimizing warehouse operations with robots and AI. He was previously former senior advisor for technology research and planning at FedEx.…

Found in Robotics News & Content, with a score of 25.79

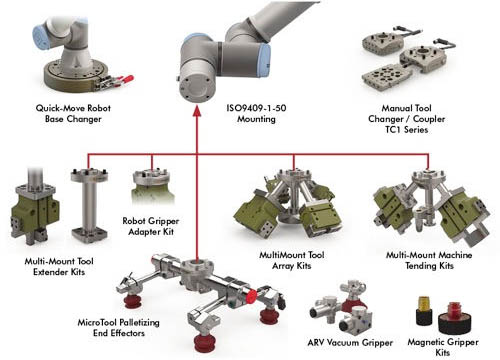

…The tools can be used to complete gripping, palletizing, machine tending, tool changing, and tool-extension applications. Destaco, a Dover Corp. company, said it is a leader in the design and manufacture of high-performance automation, workholding, and remote-handling systems. The company serves customers in a variety of end-markets, including the automotive, life sciences, consumer packaged goods, aerospace, industrial and nuclear sectors. “Small payload robots are commonly found in larger industrial manufacturing facilities, but the low-cost entry into robotic automation has recently resulted in significant growth in their use across small, light industrial, and commercial shops,” said Gary Labadie, global product director…

Found in Robotics News & Content, with a score of 16.54

…for many supply chain and manufacturing applications. RIOS Intelligent Machines Inc. said it has developed haptic intelligence for manipulation tasks that were previously difficult to automate, such as packing, machine tending, and autobagging. Smarter and more dexterous robots sound great, but how can the majority of warehouses, which are not yet automated, get started with them? Robotics 24/7 chatted with Dr. Bernard Casse, founder and CEO of RIOS, about rethinking business models as capital becomes scarce and how the robotics-as-a-service (RaaS) model can enable robot adoption. Do your due diligence Even before Silicon Valley Bank's problems, robotics suppliers and users…

Found in Robotics News & Content, with a score of 15.76

…of inserting micro components, transferring delicate objects, or even machine-tending applications,” the company said. It will be available in the second quarter of 2023, according to the company. The Grav gripper will be compatible with cobots developed by other vendors. Source: Flexiv Flexiv at ATX West 2023 Flexiv will be attending ATX West 2023 this week and plans to showcase several of its automated systems. The automation and design trade show will be held in Anaheim, Calif., from Feb. 7 to 9 at the Anaheim Convention Center. Flexiv will be at Booth 4328. “It's great to be back at ATX…