Editors’ Picks

Found in Robotics News & Content, with a score of 9.46

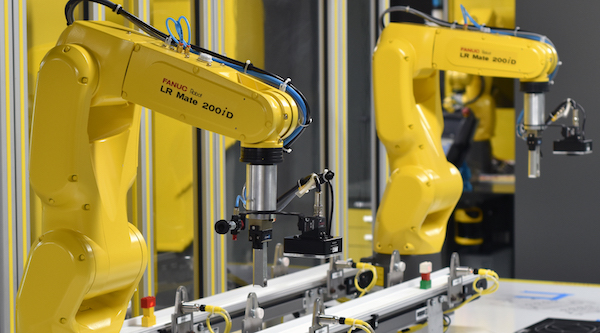

…of an auger and paint it. Also, a FANUC CRX-10iA collaborative robot will utilize a BYK-mac i end-of-arm tool (EOAT) to measure and collect color data on painted test panels. This automated process can help manufacturers determine if the final color meets their specifications, said the company. While cobots have not traditionally been used for automotive coating, the demonstration illustrates how companies can use cobots for paint inspection. In addition, FANUC experts will participate in several conference sessions at FABTECH. Editor's note: For more about FABTECH, visit Robotics 24/7's special coverage page.

Found in Robotics News & Content, with a score of 9.44

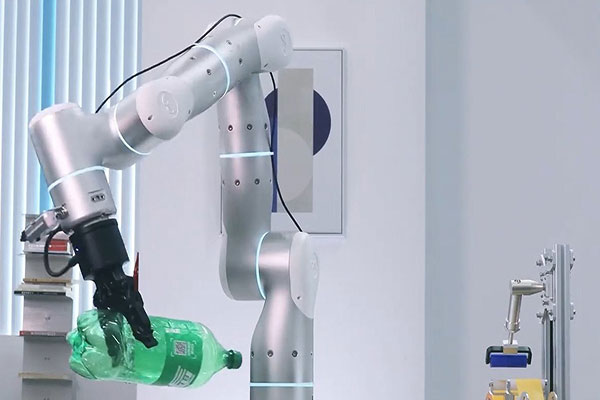

…the need for pneumatic vacuum pumps and end-of-arm tool (EOAT) changes. Automated Cleaning Station doesn’t require proprietary equipment Flexiv said it has improved its Grav Enhanced gripper so that it can now be cleaned using its Grav Enhanced Automated Cleaning Station. The cleaning station allows Rizon to operate effectively in environments where exposure to particulates could diminish the gripper's lifting efficiency, including manipulating objects covered with surface contaminants like dirt and dust. Flexiv’s new Automated Cleaning Station uses standard adhesive tape and a silicone roller to clean the Grav Enhanced gripper’s super friction material. Source: Flexiv Robotics “By packaging the…

Found in Robotics News & Content, with a score of 9.36

…motors drive the swivel units that move end-of-arm tooling (EOAT) or components to specific positions. When selecting a suitable drive, an important factor for STIWA engineers was the availability of an accessory part. “At this point in the system, we require an extremely high level of precision and repeatability,” Mersnik said. “This is why it was an important argument for us that Faulhaber was able to deliver this motor with a matching multiturn absolute encoder. The signals from this encoder are necessary to achieve the high production quality and for quality assurance.” At least 60 million fault-free strokes guaranteed by…

Found in Robotics News & Content, with a score of 9.27

…can also integrate with many types of end-of-arm tooling (EOAT), which is important for dexterity in clean room applications. These design qualities improve the robot’s ability to safely and delicately handle fragile materials. Clean room robots can also be designed with an interior vacuum or high-grade seals to prevent particulate shedding. Staubli provides six-axis arms that are rated for clean room applications. Yamaha’s clean room actuators have high-grade seals that serve a dual purpose — the seals prevent dust debris from leaking from the robot and improve suction for a performance boost. How clean room robots can work safely The…

Found in Robotics News & Content, with a score of 8.98

…inspection BeBop Sensors is in talks with end-of-arm tooling (EOAT) providers, and warehouse automation companies are interested in being able to perceive loose items or sense items when optical systems are occluded, said McMillen. “We have a short list of 80 customers and are speaking with them in order of their interest,” he said. “We have multiple pilots under way with some big warehousing and automotive companies.” “We've also anticipated apparel, because we have the ability to detect texture, not just force,” McMillen added. “We pick up variations at a pretty high sample rate and can classify them. Automating things…

Found in Robotics News & Content, with a score of 8.91

…as grippers, vision systems, rails, and other end-of-arm tooling (EOAT) and peripheral tools. At IMTS 2024, Rethink unveiled the robots and showcased integration for machine tending, palletizing, and bin picking. Riser mobile manipulation robot combines Reacher and Ryder Rethink said its Riser MMR can allow a single AMR to serve multiple stationary cobot applications. The robot combines a Ryder AMR with a Reacher cobot and an independent, detachable battery box. Rethink said the combined MMR can allow mobile manipulation to be performed at new levels of efficiency. Reacher and Ryder each have their own battery packs, requiring separate charging. Reacher…

Found in Robotics News & Content, with a score of 8.82

…camera in a protective box attached to end-of-arm tooling (EOAT). It also uses a touchscreen interface to guide the welder through the scan, teach, validate, and tuning steps. ABB added that the FlexArc U2, a member of its line of standard, pre-engineered industrial robot welding cells, can simplify the transition from manual to robotic welding. About ABB Robotics Zurich, Switzerland-based ABB Asea Brown Boveri Ltd. said it has built on more than 130 years of experience to be a leader in electrification and automation technologies. The company said it has about 105,000 employees worldwide focused on connecting “engineering know-how and…

Found in Robotics News & Content, with a score of 8.78

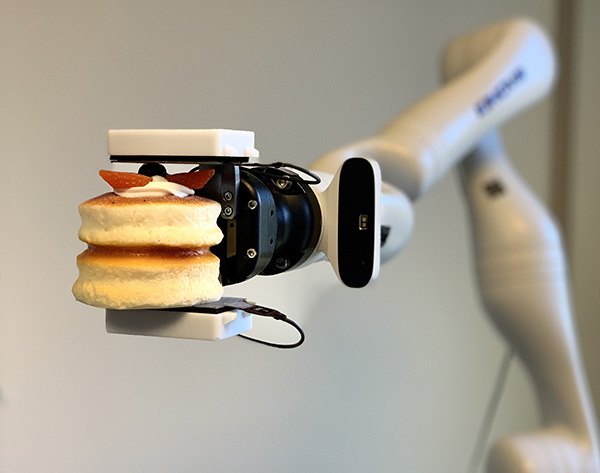

…Robotics The end result is end of arm tooling (EOAT) combined with a software platform that can identify and grasp objects to within a few millimeters. That capability creates the high level of precision required to work in a variety of environments, including a current Rapid customer that handles stuffed animals. “The grippers usually only have to handle 10 or less things,” Hummel said. “It basically means that we can really tune the gripper in a reasonable amount of time, like a week or two, to do that task very successfully.” Whether RapidID is grasping stuffed animals, cans, embalming fluid…

Found in Robotics News & Content, with a score of 7.35

…label orientation and verification, and a flexible end-of-arm tool (EOAT). The RPZ-MAX also includes easy-to-use software and a drag-and-drop, pallet-builder interface, said IRIS Automation. The demonstration at PACK EXPO will include a human-machine interface (HMI) for attendee interaction. The kiosk is designed to be intuitive, replicate the look and feel of a modern smartphone or tablet, and eliminate the need for complex programming by the user, said IRIS. The Aurora, Ill.-based company added that the RPZ-MAX uses light curtains and protected sensors and cable routing to minimize wear and maximize safety. “As clients move away from manual labor to something…

Found in Robotics News & Content, with a score of 7.11

…robot wil be equipped with an MDAC1 end-of-arm tool (EOAT), the flagship smaller-format plastic filament extruder from Massive Dimension. This display will use the 3D Printing PowerPack for ABB's RobotStudio simulation and offline programming software. The entire system offers enhanced integration capabilities and is ideal for small-scale collaborative robot applications, ABB asserted. The Dual-Arm YuMi collaborative robotic printed circuitboad (PCB) assembly cell will show how automation can accurately populate PCBs with through hold technology (THT) components. Cobots provide a viable option for low- to medium-volume orders where insertion machines would not be cost effective, said ABB. The company said its…

Found in Robotics News & Content, with a score of 6.11

…cost-effective technology for fabricating them. End effectors End-of-arm tooling (EOAT) and grippers are essential to the usefulness of the robot arms to which they're attached. With tool changers, they allow robots to perform multiple tasks and interact with various objects simultaneously. CNC machines can help create end effectors with an excellent surface finish of about Ra 0.8 μm. Controllers and sensors Sensors and controllers include printed circuit boards, or PCBs, required for various machining operations. CNC machines aid in the fabrication of controllers and sensors without the use of hazardous chemicals. Integrating CNC machines and automation Manufacturers can build productive…

Found in Robotics News & Content, with a score of 6.03

…Some cobots have cameras mounted near the end-of-arm tooling (EOAT) or even inside the grippers. Why not just rely on vision? “Putting a camera inside the gripper takes a whole computer to calculate—simpler is always better,” Sullivan replied. “To train spatial sense to be similar to vision, we realized that we needed to augment visual perception with tactile. This involves both our computer vision and data analytics groups.” “We've been using a range of sensors,” said Vetro. “Alan's group was using pressure sensors, and Daniel's group was using sensors with MIT. We've seen cameras to look at depth deformations inside…