Editors’ Picks

Found in Robotics News & Content, with a score of 21.01

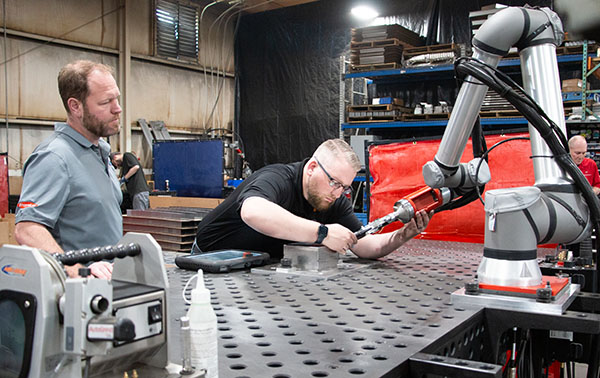

…is billed as “North America’s biggest metal forming, fabricating, welding and finishing event.” The new robot has an additional 18 in. of reach radius, or a 36-in. diameter increase, greatly broadening the range of weldments that will be achievable in a given fixture setup, said Josh Pawley, co-founder of Vectis Automation, a Universal Robots partner. “Vectis Automation is ecstatic to offer the long-reach UR20 arm onto our integrated cobot welding and cutting tools,” he stated in a release. “This cobot will have a huge impact on the market, improving on UR’s already robust and high-performance cobot products.” Pawley noted that…

Found in Robotics News & Content, with a score of 20.86

…manufacturer, the Robotics Manufacturing Hub team designed a robotic welding and grinding system for welded parts. They tested and compared grinding finish results of different abrasive, force, and speed combinations along with robot path planning. The team also compared the results of manual welding with those achieved by robotic welding. The ARM Institute’s research showed to Keystone Ridge not only that it is possible to adapt their manual processes to automated ones, but also physically showed that the desired quality of finish can be achieved through robotics. This work culminated with a highly-interactive half day in the Robotics Manufacturing Hub…

Found in Robotics News & Content, with a score of 20.57

…Equity Partners. Acieta expands Angeles’ machine tending, palletizing, and welding offerings across a broader set of end markets including agriculture, foundry and die, welding and fabrication, and construction and building products. Acieta offers standardized and customizable robots Headquartered in Waukesha, WI, Acieta is a full-service industrial automation provider with systems, controls and software engineering capabilities. Since 1983, Acieta has built a large standardized robotics business and installed over 5,500 robots. “Our team is eager to help build what we believe is the country’s most technically capable and experienced automation systems integrator,” said Robby Komljenovic, Acieta CEO. “This combination is designed…

Found in Robotics News & Content, with a score of 20.03

…production of metal parts,” said Thomas Bräuer, Bräuer Group welding engineer, “The Meltio Engine integrated with our KUKA robots makes it possible to achieve geometry freedom as well as free us from size constraints.” M600 metal 3D printer designed to make large metal parts Meltio offers a metal 3D printing system that equips industrial applications with a process built around welding wire metal feedstock. The company just presented its latest product, the Meltio M600 metal 3D printer for printing large metal parts, which Meltio said it has tailored to meet the needs of industrial manufacturing with 24/7 production cycles. 3D…

Found in Robotics White Papers & Archives, with a score of 20.01

…changing how tasks such as machine tending, packaging, and welding are done. However, many small and midsize enterprises (SMEs) are reluctant to invest in systems for high-mix, low-volume applications. Integrators must evaluate the latest sensors, software, and end effectors for different use cases. In addition, researchers, integrators, and end users must consider the level of interaction with human co-workers, environmental conditions, and the safety of different payloads. In this Special Focus Issue, we consider how cobots have become a fast-growing segment of automation and how suppliers are turning their focus to specific applications. This free download covers the following: How…

Found in Robotics News & Content, with a score of 19.72

…600,000 welders in the U.S., according to the American Welding Society. Welding robots can help mitigate this shortage, but they need to accommodate customization. “All of our customers having a hard time hiring welders, whether they're in construction, agriculture, or automotive manufacturing,” said Dmitry Golitsyn, co-founder and chief technology officer of ABAGY. “Robots haven't been flexible or adaptive enough for non-serial production, and the time needed to reprogram them is not cost-effective,” he told Robotics 24/7. “We developed software for industrial robots to use computer vision, eliminating the need for programming.” “Teach pendants don't work for non-serial manufacturing; they're designed…

Found in Robotics News & Content, with a score of 19.69

…for sandblasting, thermal spraying, shot peening, sanding, polishing, and welding applications at the show at Hall 11 Stand A45. The company said it is attending the show to help expand its presence in the European market and better demonstrate its simplified robot programing solutions. Augmentus claimed to serve a diverse customer base across various industries, such as aerospace, automotive, maritime, and supply chain. Its systems are used by companies such as ST Engineering, Hyundai, Abrasive Engineering, Johnson & Johnson, and Fujitsu. Augmentus aims to make automation simpler The company was established in 2019 and claims to be a pioneer in…

Found in Robotics News & Content, with a score of 19.20

…growth within complete robotic systems for applications such as welding, palletizing, and machine tending, propelled by UR partners creating full solutions powered by our collaborative robot arms.” Sales of UR cobots for integration in OEM (original equipment manufacturer) systems grew about 50% in 2022, said Universal Robots. The company said it began the new year with more than 80 OEM integration partners and over 300 UR+ partners launching application kits and components certified to work with its cobots across industries. Welding a growth area for cobots A significant share of new cobot-powered turnkey systems now handle welding applications, noted Universal…

Found in Robotics News & Content, with a score of 19.20

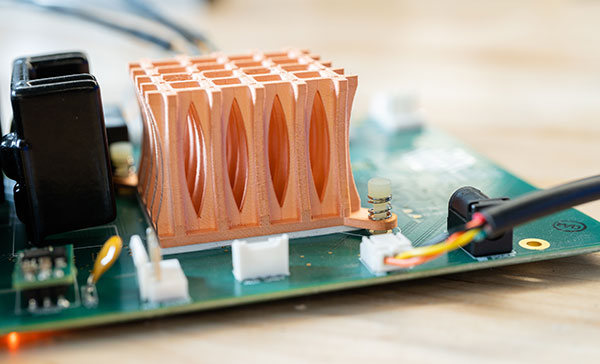

…manufacturing costs and improve supply chain efficiency. Automotive Spot Welding “Complex production parts are required to weld tight spots of the car body,” Mark adds. “They cost thousands of dollars to make and can have months-long lead times. But Markforged is changing all of that by enabling manufacturers to produce parts in-house so they get them faster and for significantly lower costs. With our 3D printed parts, automotive manufacturers can print the parts they need on demand instead of holding significant inventory and will be able to design new kinds of welding shanks that were never before possible.” Hundreds of…

Found in Robotics News & Content, with a score of 19.14

…a proven executive that delivered exceptional results for ITW Welding Group, a well-respected technologies organization. We are fortunate to have Scott join our executive leadership team, bringing a breadth of knowledge in sales, marketing and product development.” Jenkins was formerly senior vice president of sales and marketing for ITW Welding Group, overseeing all sales and marketing activities for Miller, Hobart, Bernard and Tregaskiss. Prior to ITW, he held a leadership role at Detroit Diesel Corporation for six years and also held various positions at Cummins, Inc. Jenkins brings nearly three decades of experience in industrial manufacturing and distribution to Yaskawa…

Found in Robotics News & Content, with a score of 19.02

…could handle different parts at different stations. For example, welding lock assemblies used to involve an operator who put both parts together manually before inserting them in the welding machine. The new collaborative robots (Universal Robots) and grippers (Robotiq) use plug-and-play components suited to high-mix/low-volume production. The solution also uses a robot-mounted camera able to locate parts in a wide field of view. “When the first robot arrived, the reaction of the people was not very good,” Iosif says. “They said the robot would not be able to produce at the same rate. And, they were right at first.” By…

Found in Robotics News & Content, with a score of 18.57

…SpA this week said it has built an automated welding system for Beijing Foton Daimler Automotive Co., a joint venture between Daimler Trucks AG and Chinese truck manufacturer Foton Motor. It is supporting Foton Daimler's first localized heavy-duty truck for the Chinese market, the Actros, which is based on the Mercedes-Benz global platform and uses Daimler’s truck technology. “We are honored to have been selected by Foton Daimler to work on this milestone which paves the way to localizing its first heavy-duty truck. Daimler is a global leader in the automotive industry, not only because of its large volume of…