Editors’ Picks

Found in Robotics News & Content, with a score of 6.69

…cleans it up,” he said. “The operators got different welding results, depending on the different amounts of weld applied. EFC-02 provides a window that can knock that down.” “In aerospace, we've had requests for material removal on leading edges and for honeycombed materials,” said Martinez. “We've also worked with companies that were doing fiberglass sanding, and we're looking into what we can do with woodworking.” A potential customer had an unusual request at Automate, he added. It wanted the robot to go from one place to another for a pick-and-place operation and provide a readout of force and compliance within…

Found in Robotics News & Content, with a score of 9.18

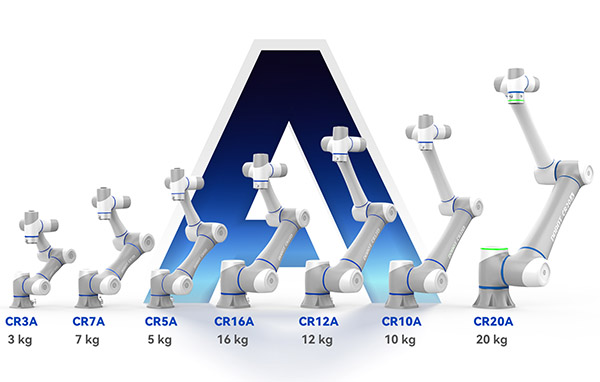

…such as pick and place, sorting, screwing, inspection, gluing, welding, transporting, polishing, and palletizing. Compared with the previous model, the CRA cobots offer a more powerful gearbox that shortens a work cycle by an average of 25%, according to the company. The control boxes of the devices are also about 25% smaller. The boxes can come with optional IP54 protection for challenging environments, reducing the need for extensive maintenance in the long term, said Dobot. Cobots come with safety, communications features In addition, electromagnetic brakes can stop the gripper arms from descending within 18 milliseconds, protecting workers in the immediate…

Found in Robotics News & Content, with a score of 6.87

…times no longer than four to six weeks in 2023. Upcoming features include an inert bubble, said Meltio. The welding industry has already implemented this hardware option to ensure the best results when printing with high-oxidizing materials such as titanium and related alloys. This could be mandatory in the aerospace sector, said the company. While the feature's final design is still in development, Meltio reiterated that the Meltio Robot Cell can increase productivity and augment manufacturing capabilities for its clients. The company said it will consider customer requests on a case-by-case basis regarding certification needs and/or low oxidation requirements.

Found in Robotics News & Content, with a score of 26.84

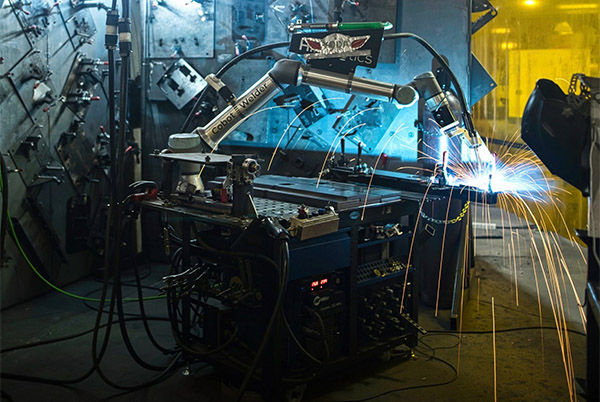

…its new Autonomous Fit-up, or AF-1, system for robotic welding this week at the FABTECH trade show in Chicago. The company claimed that the robotic cell, which can fit-up and weld metal parts, “marks a significant leap foward in the metal fabrication industry.” “Today marks a significant milestone in the advancement of American manufacturing,” said Andy Lonsberry, co-founder and CEO of Path Robotics, in a release. “We are excited to publicly unveil a system we have been developing for years that we know will change the landscape of manufacturing for years to come.” Columbus, Ohio-based Path Robotics said it builds…

Found in Robotics News & Content, with a score of 34.97

…applications shown at this week's FABTECH trade show was welding. Neuromeka Co. this week exhibited its collaborative robot for welding at the metal processing, manufacturing, and finishing event at Chicago's McCormick Place. Neuromeka said the system can help small and midsize manufacturers, particularly in the shipbuilding sector, which has been grappling with labor shortages and other disasters. “Neuromeka is a leading provider of robotic solutions, committed to enhancing automation across diverse industries,” said the Seoul, South Korea-based company, which was founded in 2013. “With a focus on innovation and safety, Neuromeka's collaborative robots are designed to elevate productivity while ensuring…

Found in Robotics News & Content, with a score of 24.60

…America Corp. plans to demonstrate its latest automation for welding and coating this week at FABTECH 2032 in Chicago. The Rochester Hills, Mich.-based company said it will demonstrate its CNC machines and robotic welding in Booth B-27015 and automated systems for painting and coating in Booth D-40523. A subsidiary of Japan-based FANUC Corp., FANUC America said it is a leader in CNC systems, robotics, and ROBOMACHINES. The company claimed that its innovative technologies and proven expertise help manufacturers in the Americas maximize productivity, reliability, and profitability.” CRX cobots offer ease of use for welding FANUC America said its collaborative robots…

Found in Robotics News & Content, with a score of 7.04

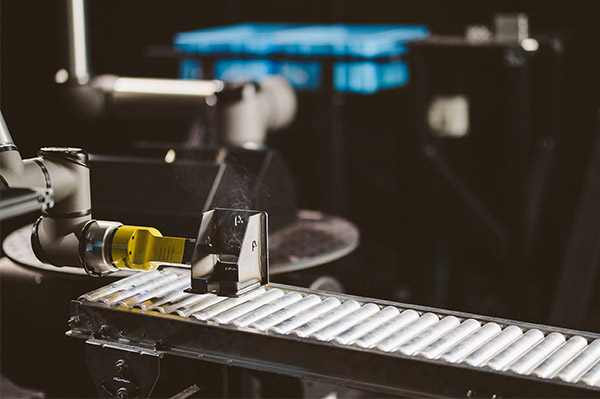

…Cobot Feeder’s 17-tray, high-density, part-storage solution enables a machining, welding, stamping, forming, or deburring center to operate for longer periods of time without human interaction, significantly increasing productivity by up to 300% or more,” asserted Beau Wileman, Applied Cobotics and 3D platform product manager at PBC Linear. “In many cases, this means a cobot workcell operating eight hours a day during normal business operations can continue to work through Shifts 2 and 3, providing lights-out operation around the clock,” he said in a release. “This considerably increases the cobot workcell’s productivity, while overcoming the ‘labor gap’ in machine tending manufacturing…

Found in Robotics News & Content, with a score of 40.41

Manufacturers use welding technology to produce a wide variety of metal goods, and FABTECH 2023 will provide an opportunity to see several demonstrations of automated welding. Han's Robot Co. will be showing its Automated Welding Workstation system in Chicago this week. The scope of welding applications includes manufacturing of everything from automobiles and aircraft to household appliances, noted Han's Robot. The Shenzhen, China-based company said in a release that its Automated Welding Workstation (Gas Shielded Arc Welding) Application Solution is built around its Elfin-Pro collaborative robots to improve efficiency. Han's Robot touts welding workstation features Han's Robot said its Automated…

Found in Robotics News & Content, with a score of 17.45

…events will focus on three applications within industrial automation: welding, machine tending, and palletizing. The events will be broadcast live from Universal Robots’ three Centers of Excellence across the globe. Palletizing: Sept. 28 from Barcelona, Spain Machine tending: Oct. 12 from Munich, Germany Welding: October 26 from Novi, Mich. The company said all three events are free to attend, and they will feature: Talks with experts and industry leaders Successful customer case stories Live demonstrations of the latest UR20 robots Live Q&A sessions with industry experts Universal Robots provided more information and free registration at its website. UR cobots conduct…

Found in Robotics News & Content, with a score of 21.01

…is billed as “North America’s biggest metal forming, fabricating, welding and finishing event.” The new robot has an additional 18 in. of reach radius, or a 36-in. diameter increase, greatly broadening the range of weldments that will be achievable in a given fixture setup, said Josh Pawley, co-founder of Vectis Automation, a Universal Robots partner. “Vectis Automation is ecstatic to offer the long-reach UR20 arm onto our integrated cobot welding and cutting tools,” he stated in a release. “This cobot will have a huge impact on the market, improving on UR’s already robust and high-performance cobot products.” Pawley noted that…

Found in Robotics News & Content, with a score of 32.26

…will be showing its new products and capabilities for welding and cutting with collaborative robot arms at FABTECH 2023, which will be from Sept. 11 to 14 in Chicago. “We are excited to unveil our new products and capabilities at FABTECH,” said Rob Goldiez, CEO of Hirebotics. “We are proud to offer the most advanced and user-friendly robotic welding and cutting solutions on the market. These game-changing tools and flexible solutions will enable our customers to more quickly and easily integrate our cobot welders to their manufacturing facilities.” Nashville, Tenn.-based Hirebotics said in a release that it is a leading…

Found in Robotics News & Content, with a score of 24.39

…enterprises, fabrication job shops, and first-time users of robotic welding equipment. ”With an emphasis on flexibility, accuracy and ease of use, ABB’s mission is to provide the benefits of the automation industry’s most comprehensive and integrated portfolio of industrial and collaborative robots to metal fabricators of all levels of technical sophistication,” stated John Bubnikovich, president of ABB’s U.S. Robotics Division, in a release. ”Businesses of all sizes must continue to manufacture the highest quality components as they manage labor shortages and the growing demand for customized products.” ABB will show its systems at FABTECH Booth B17053 from Sept. 11 through…