Editors’ Picks

Found in Robotics News & Content, with a score of 25.00

…the first Class II, Division 1 (C2D1) end-of-arm tool (EOAT) sander. It is based on FerRobotics' Active Orbital Kit (AOK) with patented Active Compliant Technology and can improve efficiency and safety, they said. Aerobotix works to make aerospace jobs safer Each year, tens of millions of workers globally are afflicted with silicosis, an incurable lung disease caused by crystalline silica dust inhalation, leading to thousands of deaths, according to the International Labour Organization. Many jobs in the aerospace and defense industries involve combustible, dangerous dust created by sanding. The invention of a force-compliant C2D1-rated automated sander, with integral dust collection,…

Found in Robotics News & Content, with a score of 7.35

…label orientation and verification, and a flexible end-of-arm tool (EOAT). The RPZ-MAX also includes easy-to-use software and a drag-and-drop, pallet-builder interface, said IRIS Automation. The demonstration at PACK EXPO will include a human-machine interface (HMI) for attendee interaction. The kiosk is designed to be intuitive, replicate the look and feel of a modern smartphone or tablet, and eliminate the need for complex programming by the user, said IRIS. The Aurora, Ill.-based company added that the RPZ-MAX uses light curtains and protected sensors and cable routing to minimize wear and maximize safety. “As clients move away from manual labor to something…

Found in Robotics News & Content, with a score of 12.89

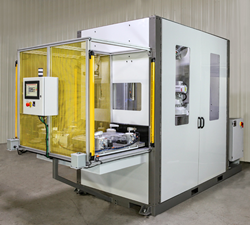

…ABB IRB 2600 robot and a multiple-purpose end-of-arm tool (EOAT) mounted to the robot. The deburring and pre-machining system automatically removes excess material from die-cast aluminum parts. The parts arrive from the casting deck, are inspected, and loaded into one of the two fixtured shuttles in the MiniMAC, the robot and tool remove the unwanted materials from each part and the finished part is returned to the operator complete. Other features of the MiniMAC Grind System, include choices in robot model, part presentation techniques, and tooling used to remove excess materials. Each MiniMAC cell and the larger MAC and MegaMAC…

Found in Robotics News & Content, with a score of 17.80

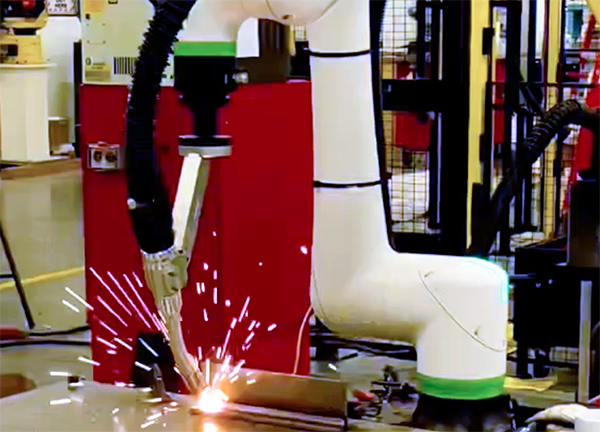

…off his company’s welding and plasma cutting end-of-arm tools (EOAT). He said it takes years of practice for a welder to become a master of his craft. With the use of robots, companies can get that precision in less time. “It is extremely difficult and takes a long time to get proficient at welding, at least to the point where you can make a career out of it,” Eckdahl said. “I’m not a welder by any means, but I can make the robot put down some very pretty wells.” During the open house, Vectis’ cobot was emulating the motions of…

Found in Robotics News & Content, with a score of 10.67

…component in the finished product. Specially designed end-of-arm tooling (EOAT) allows for highly stable and exact positioning of labels. 5. Applications for automation in post-processing Post-processing robots can inspect, test, and hot-stamp plastic molded parts. For example, an eight-axis robotic trimming cell provides superior repeatability compared with a human performing the same task. Robots can also improve precision, accuracy, and cycle times, lessening waste and minimizing errors. Simply put, robots can make a big difference in cost-effectiveness and production waste while freeing workers from repetitive manual work. Robotics has tremendous potential to change the future of business operations. The robotics…

Found in Robotics News & Content, with a score of 53.60

…hunt to improve their supply chain processes. End-of-arm tools (EOAT) allow robots to have better control, accuracy, and precision, enabling autonomous systems to have more capabilities. There are a wide range of robot arm tools, including grippers, collision sensors, and welding torches. Materials handling is a big market for EOAT The EOAT market is estimated to increase by $892 million between 2020 and 2025, according to the report “Robotics End-Of-Arm Tooling Market by Application and Geography—Forecast and Analysis 2021-2025” from market research firm Technavio. “Manufacturers have been increasing their investments in industrial robots for assisting in a varied range of…

Found in Robotics News & Content, with a score of 24.10

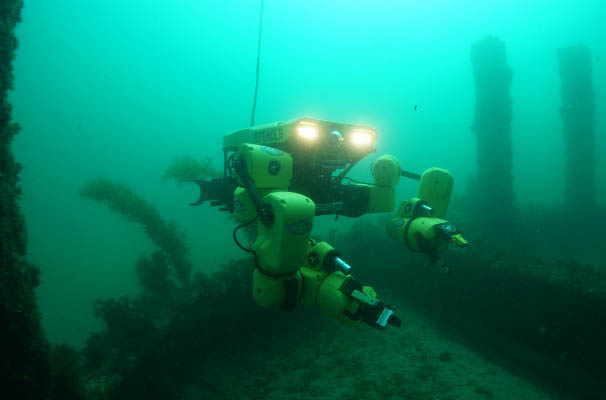

…and holding a variety of objects. The end-of-arm tooling (EOAT) project is funded through the U.S. Navy's Office of Naval Research (ONR). “STARFISH uses advanced touch sensors and next-generation haptic feedback to provide robot operators with the last link in terms of robotic perception capabilities—the ability to ‘feel’ objects in the environment,” said Dr. Adam Brant, project manager at Sarcos. “This will enable EOD personnel to locate, sense, and interact with objects they both can and cannot visualize from a remote, safe distance.” STARFISH demonstrates a deft touch During lab testing, the STARFISH prototype used three tactile-sensing fingers to successfully…

Found in Robotics News & Content, with a score of 17.01

…Tool changing increases in speed, importance As end-of-arm tooling [EOAT] technologies improve in precision and more industries look to automation, gripper makers have kept busy. Software advances are big driver, as user interfaces have become easier to use. On the hardware side, there are new engineering feats such as the introduction of seven-axis collaborative robots and new grippers outfitted with force sensors. Customers are always asking for more precision, speed, and flexibility, Green said. Getting customers the systems they desire takes a combination of many different types of technologies. “You really need to marry a number of different technologies into…

Found in Robotics News & Content, with a score of 15.66

…FastARC CX1000 can be available for delivery and installation within just weeks, according to Acieta. With many end-of-arm tooling (EOAT) options, the CX1000 can be uncoupled from the weld cart and repurposed for different applications such as machine tending or sanding when not welding. The FastARC CX1000 cobot is equipped with a FANUC six-axis, 10-kg (22 lb.)-capacity cobot arm that Acieta said is maintenance-free for up to eight years. The system is compatible with Lincoln Electric and Miller Electric welders and is IP 67-rated with sealed components to work in industrial environments.

Found in Robotics News & Content, with a score of 13.04

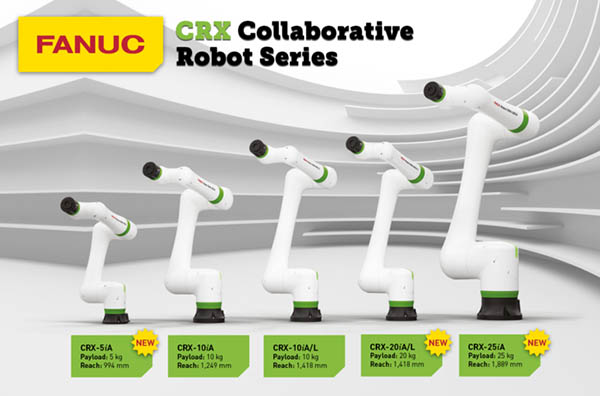

…models are designed to be easy to connect to third-party devices, including FANUC-approved CRX device suppliers for end-of-arm tooling (EOAT), grippers, accessories, and plugins. Industrial automation suppliers interested in having their products become part of the CRX device program should contact FANUC. Demos and shipping to come FANUC plans to demonstrate all five CRX models at IREX (International Robot Exhibition) Virtual from March 1 to 18, and at IREX from March 9 to 12, at the Tokyo Big Sight in booth E4-04. The company said it will begin shipping production units of the new CRX-20iA/L in April. The CRX-25iA and…

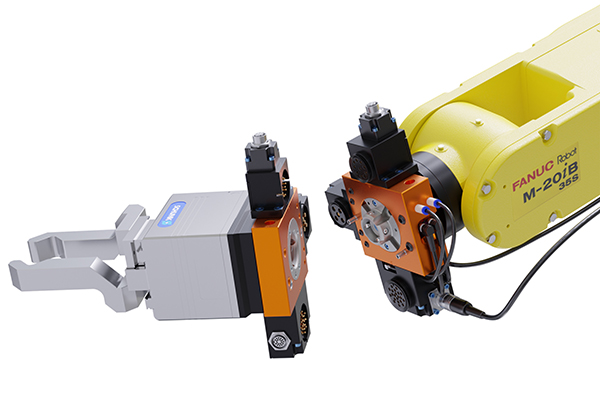

Found in Robotics News & Content, with a score of 17.89

…tooling. The Apex, N.C.-based company said its end-of-arm tooling (EOAT) can enhance the productivity and flexibility of automation across a wide spectrum of industries. It provides automatic tool changing, force-torque sensing, material removal, and more capabilities. In July, Novanta Inc., a Bedford, Mass.-based industrial and medical equipment manufacturer, said it planned to acquire ATI for $172 million. ATI designs QC-29 for robust light robot tool changing The QC-29 Robotic Tool Changer includes a tool-side plate (left) that connects to the customer tooling and a master side plate (right) that connects to the robot wrist. Additional tool plates can be purchased…

Found in Robotics News & Content, with a score of 14.84

…of the mobile robot world Just as end-of-arm tooling (EOAT) make it possible for industrial robots such as collaborative robot arms to actually grasp and manipulate objects, mobile robotic equipment makes it possible for an AMR to successfully collect goods and transport them through a facility. And just as cobots are components within an overall automation deployment that requires EOAT, AMRs are components of a complete mobile automation deployment that requires MREs. Without doubt, not all equipment is created equal, and there are significant differences in terms of functionality, usability, and compatibility among various offerings, but without MRE of some…