Editors’ Picks

Found in Robotics News & Content, with a score of 31.45

…added the Carbon platform to its portfolio of production-grade additive manufacturing technologies. With Carbon Digital Light Synthesis (DLS), the goal is to enable Protolabs’ customers to move into production faster and more cost-efficiently with 3D printing, the companies say. “We recognize that market demand for additive manufacturing has moved beyond prototyping and is being leveraged to create fully functional parts at much larger scale,” says Greg Thompson, Protolabs’ global product manager for 3D printing. “We are committed to supporting that demand in a technology-agnostic manner so that our customers get the best possible parts from the best possible 3D printing…

Found in Robotics News & Content, with a score of 34.96

Additive Industries North America, Inc. announces the purchase of six MetalFAB1 systems by an aerospace company located in California. This firm order validates the Additive Industries’ concept of production-based metal powder bed fusion systems for overall equipment efficiency. When the order for six machines arrives at the customer site later this year, it will bring the installed base of MetalFAB1 systems to 10 with more possible in 2020, Additive Industries reports. This customer was able to consolidate approximately 700 kg of powder in June with the four laser MetalFAB1 systems currently in operation. The application represents an inflection point in…

Found in Robotics News & Content, with a score of 43.29

Renishaw, a precision engineering and manufacturing technologies company, worked with Michigan-based Cobra Aeroto to improve the engine manufacturer’s design processes for aircraft and motorcycle engines. After completing the project with Renishaw, Cobra Aero invested in an AM 400 system to increase its in-house additive manufacturing (AM) capabilities. To optimize the design of its engine cylinders and to gain expertise in AM, Cobra Aero visited a Renishaw Additive Manufacturing Solutions Center. There they collaborated with Renishaw engineers to discover how AM could improve the design of a cylinder for an unmanned aerial vehicle (UAV). “Investing in AM allows us to develop…

Found in Robotics News & Content, with a score of 8.27

…into four tracks: Simulation-Driven Design, Simulation Governance & Democratization, Manufacturing Processes & Additive Manufacturing, and Business Strategies & Challenges. However, the path to truly democratized simulation requires both technological and cultural changes. Digital Engineering spoke with some leading industry organizations about progress toward this democratization, and some of the remaining challenges and opportunities. We spoke to Matthew Ladzinski, vice president, Americas and special projects, NAFEMS; Joe Walsh, CEO of the ASSESS Initiative; Malcolm Panthaki, co-founder and executive committee member, Rev-Sim.org and VP of Analysis Solutions at Aras; and Chris Smith, senior analyst and cloud computing SME at Smart2Market. Digital Engineering:…

Found in Robotics News & Content, with a score of 13.33

Manufacturing is changing. Never mind the remarkable utility of 3D scanning, the customization capability of additive manufacturing, or the facile methods of rapid prototyping—there’s a whole new way of using cloud computing to disseminate design information instantly. Potentially, it provides a new chapter in the way we manufacture everything. Welcome to contract manufacturing—also known as manufacturing as a service (MaaS). “For decades now, companies have shifted from vertically integrated design, engineering and manufacturing, to relying on external contract manufacturing partners,” says Andrew Edman, industry manager for product design, engineering, and manufacturing at Formlabs in Somerville, Mass. “Even manufacturers that continue…

Found in Robotics News & Content, with a score of 25.92

…engineering. Through this partnership, the companies intend to develop manufacturing solutions, including 3D printers, materials and software—to change automotive design and production. “TMG has chosen 3D Systems for this partnership because they share our pioneering spirit—exhibited by the fact that they introduced the world to 3D printing. We see the unparalleled potential of combining 3D Systems’ expertise and know-how with that of TMG to create technologies and define new additive manufacturing innovations in the automotive industry,” says Andreas Schambach, project general manager future production technology, TOYOTA Motorsport GmbH. 3D Systems and TOYOTA Motorsport set up an automotive-focused partnership. Image courtesy…

Found in Robotics News & Content, with a score of 35.36

…has been elected to serve as chairman for SME’s Additive Manufacturing (AM) Community. SME’s AM Technical Community Advisors serve as the primary resource for guidance to SME and its members on AM technologies, including materials, processes, industrial base and workforce. The primary responsibility of the SME AM Advisory Committee is to advise SME on initiatives, activities, policy, and strategy related to AM. “AM continues to be a major strategic initiative for SME and a vital emerging sector for manufacturing as a whole,” says Suzy Marzano, product development manager at SME who oversees SME’s Technical Communities. “We’re thrilled at Zach’s selection…

Found in Robotics News & Content, with a score of 41.43

…Ginn College of Engineering has begun in-process inspection of additive manufactured parts using a customized digital radiology vault and specialized additive manufacturing systems designed by Auburn University researchers. The new system was acquired through a $1.5 million grant from the National Institute of Standards and Technology awarded to Auburn's Center for Additive Manufacturing. Auburn's Center for Additive Manufacturing was formed in 2015 and now includes extensive collaboration between Auburn, NIST, NASA and the global standards organization ASTM International. The nationally recognized organization conducts research, trains and educates graduate and undergraduate students, and develops and promotes technological innovations that advance the…

Found in Robotics News & Content, with a score of 20.45

…NIST (National Institute of Standards and Technology) video, Rethinking Manufacturing, that aired on Monday, August 19 at 4:30 p.m. at YBI’s “Tech Block Building Five.” The Rethinking Manufacturing video features two Youngstown natives and promising engineers, America Makes Project Engineer Ashley Totin and JuggerBot 3D co-founder and president Zac Divencenzo, and their journey to find their career paths in the wake of the economic decline of their hometown. Once a thriving steel town, the collapse of the industry in the 1970s hit Youngstown particularly hard. During the following decades, Youngstown experienced harsh economic times due to significant job losses that…

Found in Robotics News & Content, with a score of 17.00

Fortify, a Boston-based additive manufacturing start-up and pioneer in digital composite manufacturing (DCM), announced it has closed a $10M Series A funding led by Accel with additional participation from Neotribe, Prelude Ventures and Mainspring Capital Partners. The funding will support the launch of Fortify’s Discovery Partner Program and the growth of the Fortify team. This follows a previous seed round this year of $2.5M. Fortify’s “Fluxprint” technology combines magnetics and digital light processing (DLP) 3D printing to produce composite parts with optimized mechanical properties. This is achieved by precisely orienting reinforcement fibers throughout the parts. Founded on research in composite…

Found in Robotics News & Content, with a score of 19.94

Nano Dimension Ltd. has introduced its DragonFly Lights-Out Digital Manufacturing (LDM) printing technology, a comprehensive additive manufacturing platform for round-the-clock 3D printing of electronic circuitry. The DragonFly LDM system is designed for Industry 4.0 and manufacturing for the Internet of Things and is the extension of the successful DragonFly Pro precision system, which is dedicated to printing electronic components such as multilayer printed circuit boards (PCBs), antennas, capacitors and sensors. The DragonFly LDM is already available through Nano Dimension’s global sales channel. In Germany, the launch of the DragonFly LDM was already initiated by Nano Dimension’s reseller, Phytec New Dimension.…

Found in Robotics News & Content, with a score of 12.69

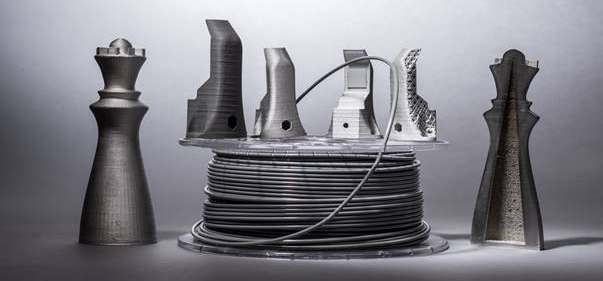

…Minec, managing director, BASF 3D Printing Solutions. “Our goal was to develop a high-quality metal filament that makes the additive manufacturing of metal parts considerably easier, cheaper, faster, and accessible to everyone.” Sources: Press materials received from the company and additional information gleaned from the company’s website.