Editors’ Picks

Found in Robotics News & Content, with a score of 18.45

…have (so far) failed to materialize, the applicability of additive manufacturing (AM) today is no less impressive. Most of the things made with AM over the past year weren’t futuristic gadgets—although here’s a list of “50 cool things to 3D print in October 2019”—they’re real and tangible products that are expected to add $7 billion to the global economy in 2019. And while some applications of 3D printing really do have the ability to change the world—check out these 3D printed houses, for instance—the majority of application potential lies in the innovations that AM enables. By giving companies the ability…

Found in Robotics News & Content, with a score of 18.36

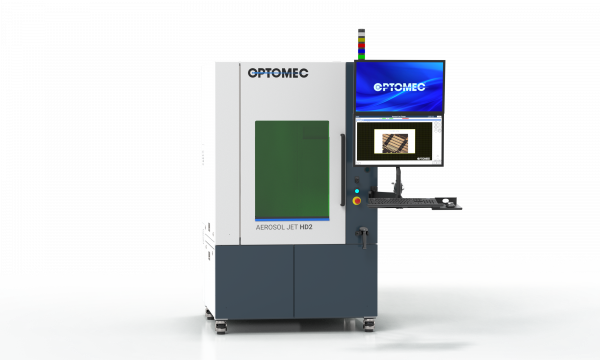

…various materials including common polymers, IC materials, FR4, glass, ceramic and metals. The HD2 was designed for high volume manufacturing and includes production-friendly software that guides operators through a simplified start-up process, ensuring QA compliance. The machine is also available with an in-line conveying option for automated part loading. It can process substrates or part trays up to 300-mm wide and is available with a rotate table for four-axis processing.

Found in Robotics News & Content, with a score of 18.24

…satellites to orbit. In April, Launcher purchased a metal additive manufacturing system to print Inconel parts, and it recently added another one that prints titanium. “Rocket engine turbopump parts typically require casting, forging, and welding,” said Max Haot, founder and CEO of Launcher. “Tooling required for these processes increases the cost of development and reduces flexibility between design iterations. The ability to 3D print our turbopump—including rotating Inconel-shrouded impellers, thanks to Velo3D’s zero-degree technology—makes it possible now at a lower cost and increased innovation through iteration between each prototype.” Inconel is a family of nickel-chromium-based superalloys trademarked by Special Metals…

Found in Robotics News & Content, with a score of 18.06

SME, a professional association committed to advancing manufacturing professionals, academia and communities, announces that 15 achievers have been selected to receive the 2020 SME Outstanding Young Manufacturing Engineer Award. A 2020 SME Outstanding Young Manufacturing Engineer, Michael P. Sealy, Ph.D., is an assistant professor in the Department of Mechanical & Materials Engineering at the University of Nebraska—Lincoln. Sealy was one of 15 awardees selected. The 2020 awardees, from the U.S. and Canada, have centered their research and management efforts around manufacturing processes, environmental sustainability, additive manufacturing, smart manufacturing, medical device manufacturing, nanomanufacturing, biomedical manufacturing, metalworking fluids, civil and environmental engineering,…

Found in Robotics News & Content, with a score of 18.03

…state and university programs in the U.S., and global additive manufacturing OEM programs. This is not a comprehensive list and some programs may require additional fees, specific products and materials, prior government compliances or agreements, membership or other requirements. AMUG advises its members to tap into their AM network and participate in programs that are in line with respective organizations' capabilities and resources. If you are part of a regulated (controlled) program in the Americas, Asia, Europe or Oceania region that is not listed here, please email the information to [email protected]. AMUG says it will do its best to add…

Found in Robotics News & Content, with a score of 18.00

…face.” Five critical geometries and dimensions used in the manufacturing of N95 masks will be made available to challenge participants for them to develop up to three masks. Submissions will be accepted until 11:59 p.m. on Sunday, April 26, with five designs going to the VA for fast track review and testing, and the top design(s) being announced on May 11, 2020. Interested participants can find more information here. Challenge America and VHA Innovation Ecosystem COVID-19 Makers Challenge: April 25 - May 3, 2020 America Makes is proud to promote the COVID-19 Makers Challenge, an event being hosted jointly by…

Found in Robotics News & Content, with a score of 17.76

…material properties. This effort led ARDEC to expand into additive manufacturing, specifically, to identify the types of materials that can be used in AM equipment to meet the needs of the US Army. Matthew Brauer, a scientist for the Advanced Materials Branch of ARDEC, said that with approximately 25 3D printers in their lab, ranging from small, $500 hobby-class desktop machines to large $500K+ industrial-class additive manufacturing equipment, they are always looking for the latest equipment to test and use for their unique applications in the field, where soldiers need spare parts and custom tools on demand. Challenges U.S. Army…

Found in Robotics News & Content, with a score of 17.76

…of our 3D Printing Solutions by Arkema platform vision, aiming to identify new opportunities to support successful adoption of additive manufacturing,” says Summit Jain, global director for 3D Printing Business, Sartomer. “Joining forces to design E-Aquasol resin for our professional-grade Continuous Digital Light Manufacturing DLP 3D printing platform supports our customers in achieving the best end results thanks to the advanced performance properties of this water-soluble material,” Al Siblani, CEO, EnvisionTEC, adds. The debut of E-Aquasol was announced at Formnext in Frankfurt, Germany. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 17.75

…printers, and will shortly be releasing a new 3D additive manufacturing ecosystem (the 5200), which HP says will bring “new levels of manufacturing predictability, efficiency, repeatability, and quality” to volume part production. They are doing what HP has done for 70 years, use existing products to jumpstart research. From an audio oscillator for its first customer (Walt Disney Company) to microwaves, from calculators to personal computers, and now from 2D wide format printers to 3D, HP is putting its considerable size and vast R&D expertise to work in additive manufacturing. “The future is distributed manufacturing,” HP’s Ramon Pastor, general manager…

Found in Robotics News & Content, with a score of 17.75

…U.S. government agencies. Markforged 3D printers are used in manufacturing everything from automobiles to aircraft engines. The company offers metal printers with the entire range of metals—from high-conductivity copper to industrial tool steel to superalloys like Inconel—all in a safe, fast and easy-to-use platform. Its industrial composite platform can print in continuous carbon fiber, Kevlar and more, creating functional parts. Markforged has a strong history of technology involvement in the government and defense sectors, as branches of the U.S. military have hundreds of machines in operation today. The company implemented a forward-deployed metal system to support combat operations and now…

Found in Robotics News & Content, with a score of 17.58

…gave the media a peak inside its new Advanced Manufacturing Center, a $45 million facility in Redford that will use 3D printing, virtual reality, simulation and collaborative robots to create new innovations in vehicle production. “More than 100 years ago, Ford created the moving assembly line, forever changing how vehicles would be mass-produced,” said Joe Hinrichs, Ford’s president of Global Operations. “Today, we are reinventing tomorrow’s assembly line — tapping technologies once only dreamed of on the big screen — to increase our manufacturing efficiency and quality.” The 3D printing in the facility includes the additive manufacturing of brake parts…

Found in Robotics News & Content, with a score of 17.55

…in technology are changing how business is done. The manufacturing industry in particular is becoming more efficient, as production, assembly, and supply chain operations add automation. Learn more about the increasing role of technology across manufacturing in the infographic below. Technology is affecting numerous areas of manufacturing through a broad range of methods, tools, and processes. They include: Remote monitoring and sensors Artificial intelligence Automation integration Digital twins Computerized maintenance management systems (CMMS) Additive manufacturing Areas of manufacturing benefiting from tech Here are some key areas where technology is rapidly increasing, expanding, and changing the face of the manufacturing industry.…