Editors’ Picks

Found in Robotics News & Content, with a score of 17.10

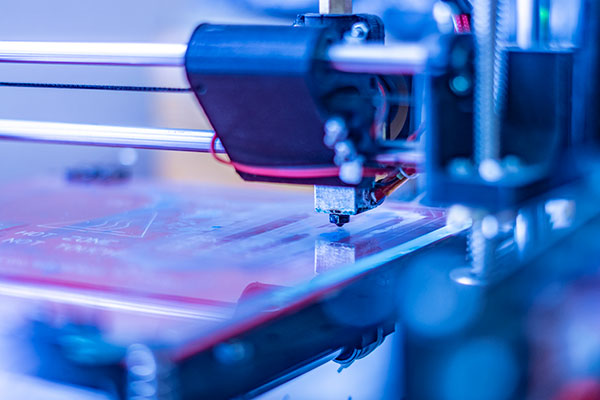

The current capabilities of additive manufacturing (AM) are the result of 30 years of invention and innovation. Yet there is so much about the technology that remains a promise. Currently most 3D printers used for AM can use only one material; a select few can print a product with two materials. The long-term vision for AM materials research is to have CAD-like tools engineers will use to model materials at any scale. Once designed, the 3D printers will blend and process multiple raw ingredients in real time. Such designer materials, engineered as part of the product development process, would spur…

Found in Robotics News & Content, with a score of 20.07

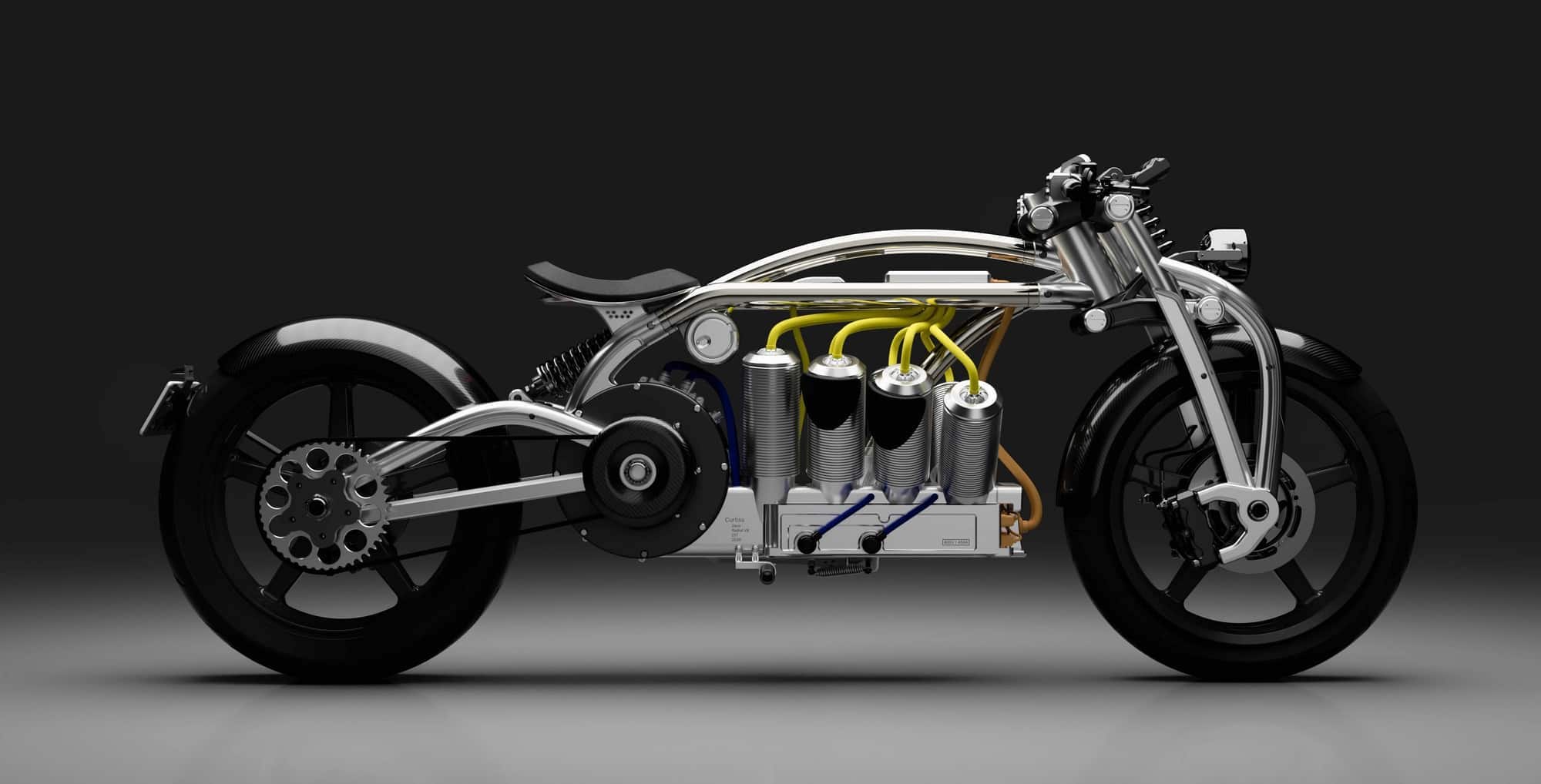

…Curtiss turned to Fast Radius, a provider of hybrid manufacturing services, to get the unique bike into production quickly so it could make its planned launch date. “We had three weeks to make it to the show—there was no chance a traditional approach to manufacturing would make that possible,” says Matt Chambers, CEO of Curtiss Motorcycles. Working with Fast Radius, the partners came up with a hybrid manufacturing approach that leveraged CNC milling, hot tube bending and additive manufacturing. Instead of trying to force a single manufacturing process for Zeus, the team leveraged the strengths of the different methods when…

Found in Robotics News & Content, with a score of 33.90

…4 Production Black 10 (PRO-BLK 10)—a production material for additive manufacturing applications that enables manufacturers to directly produce end-use plastic parts without tooling. This results in parts produced the same day versus weeks required with conventional tool-based approaches. Figure 4 PRO-BLK 10 is 3D Systems’ photopolymer for additive manufacturing that exhibits thermoplastic behaviors, providing a combination of speed, accuracy, strength and durability previously only associated with injection molding output. The material works with a simple isopropyl alcohol (IPA) wash and does not require a secondary thermal post-cure process, which significantly improves throughput yield and significantly reduces the extensive solvent cleaning…

Found in Robotics News & Content, with a score of 34.44

…The partners were to showcase 3D printed parts for manufacturing during the upcoming TCT Show September 24-26, 2019. EnvisionTEC’s new open access material program allowed for a collaboration with Henkel to further drive additive manufacturing towards the mass production of functional parts across various industries. Under the agreement with Henkel, EnvisionTEC certified Henkel´s materials for use on its 3D printers and aligned the Loctite materials portfolio to the EnvisionTEC printer solutions. Henkel will provide 3D printing solutions to its customer base across more than 800 industry segments based on EnvisionTEC's continuous Digital Light Manufacturing (cDLM) and DLP technology platforms. “We…

Found in Robotics News & Content, with a score of 35.57

…page. With many automotive and aerospace manufacturers turning to additive manufacturing (AM) in their lightweighting projects, the die casting discipline begins to feel its glory days are fading. Some ask: will AM ultimately replace die casting? Others worry that it’s not a matter of “if,” but “when”—that the fate for die casting is sealed. But Dr. Joshua Huang, the senior technical lead at Ryobi Die Casting, begs to differ. He foresees a future where the two technologies can coexist in a symbiotic fashion. With expertise in manufacturing process simulations with CFD and FEA, die casting manufacturing, and additive manufacturing, Huang…

Found in Robotics News & Content, with a score of 25.89

…enable Xaar 3D to accelerate the development of its additive manufacturing solutions based on high-speed sintering (HSS) technology. These solutions are designed for end-use parts applications in low-to-medium production volumes, primarily in the industrial segment. Xaar plc and Stratasys announced the formation of Xaar 3D Ltd in July 2018. The purpose of the joint venture is to develop high-speed sintering additive manufacturing solutions that Stratasys can bring to market. “Xaar 3D has made significant progress over the past year and we see benefits to Stratasys in extending its investment in Xaar 3D's innovative High Speed Sintering based solutions,” says Omer…

Found in Robotics News & Content, with a score of 28.30

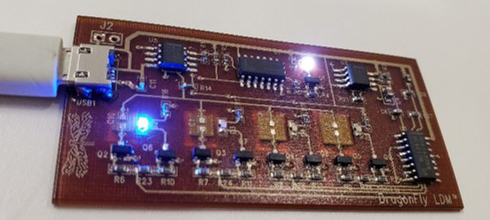

…has developed 3D printed capacitors with the company’s DragonFly additive manufacturing system. These capacitors are embedded in the body of the additively manufactured printed circuit boards (PCBs), saving space and eliminating the need for assembly, the company reports. This type of additive manufacturing of electronics validates the manufacturing applicability of built-in capacitors in PCBs printed with the DragonFly system. Nano Dimension’s testing with capacitors of different 3D dimensions have shown consistent results with statistically validated data. The repeatability results show less than 1% variance. The technology uses the same dielectric and metal traces as in the additively manufactured PCB yielding…

Found in Robotics News & Content, with a score of 33.01

…for education, research and workforce development in advanced metal additive manufacturing. NTU purchased the directed energy deposition machine with a National Science Foundation grant for use in its new Center for Advanced Manufacturing, expected to open in 2020. “We are creating a state-of-the-art lab with leading-edge technology that spans the whole metal additive manufacturing ecosystem right here on the Navajo Nation, giving our students access to critical skills for the future,” says H. Scott Halliday, director of NTU’s Center for Digital Technology and visionary behind the Center for Advanced Manufacturing. “The Optomec LENS is a critical element of our vision…

Found in Robotics News & Content, with a score of 23.84

…Team created this design guideline for 3D printing and additive manufacturing technologies—get answers for commonly asked questions specific to designing for Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Stereolithography (SLA), and PolyJet (PJ). The easy-to-use chart includes wall thickness, hole diameter, clearance for assemblies, escape holes, minimum detail, pin diameter, Z & XY accuracy, and standard layer thickness. FATHOM’s Application & Engineering Team is always adding to this chart, so check back often for any updates. Fused deposition modeling Fused Deposition Modeling (FDM) is ideal when you need to build concept models, functional prototypes, and…

Found in Robotics News & Content, with a score of 16.45

…entirely new designs in just a few days. Though many of the amputees were familiar with the concept of additive manufacturing, wearing a functional 3D printed device created a “sense of excitement, like living in the future,” Johnson describes. “I appreciate seeing that spark in somebody’s eye.” Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 55.84

As additive technologies, materials, and processes mature, so does the argument for using additive manufacturing (AM) to make production parts—let go of traditional manufacturing constraints and embrace a new mindset that explores additive manufacturing as a serious means of production. Additive Manufacturing vs. Injection Molding The additive technologies most commonly used for production of plastic parts include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). The break-even point of AM compared to injection molding (IM) was once a few hundred parts but is now pushing into the thousands with trends showing the cut-off point even…

Found in Robotics News & Content, with a score of 28.83

…to be made. FATHOM’s proven ecosystem of dynamic advanced manufacturing solutions has earned award-winning recognition year after year. The team has also been recognized on the Inner City 100 list by ICIC as published in Fortune Magazine and the San Francisco Business Times’ Fast 100 list of fastest-growing private companies in the Bay Area. Rich Stump, Co-Founder and Principal at FATHOM: “FATHOM’s culture, expertise, technologies, capabilities, quality, and customer service is driven by our strategic focus on our customers’ need for a complete experience from a brand they can trust and rely on to achieve impactful results. We’re grateful for…