Editors’ Picks

Found in Robotics News & Content, with a score of 19.63

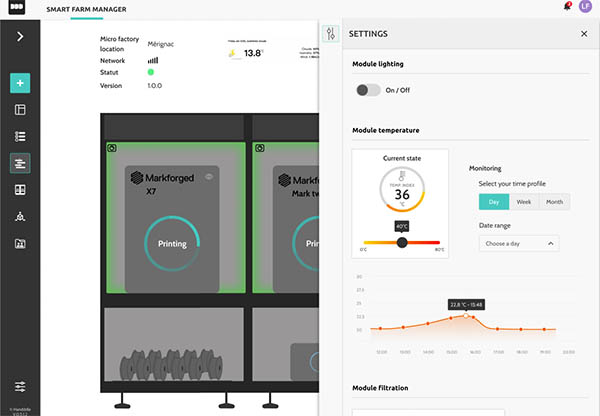

Environmental conditions such as temperature and humidity can affect additive manufacturing, so process monitoring can help standardize production. Handddle and Markforged yesterday said they are integrating Handddle's “micro-factories” platform and other management tools with the Markforged Digital Forge software. “Handddle is thrilled to collaborate with Markforged to extend API integrations for Handddle and Markforged users looking to achieve industrial efficiencies to address quality challenges in strategic markets,” said Dylan Taleb, co-founder and chief operating officer of Handddle. “Thanks to this collaboration, manufacturers will be able to rely on an integrated solution to develop their knowledge and control of production processes…

Found in Robotics News & Content, with a score of 19.42

…help a hospital treat patients. America Makes, the National Additive Manufacturing Innovation Association, is assembling a resource portal to help produce the Personal Protective Gears that are in shortage in the hospitals. Similarly 3D Systems is also calling the Additive manufacturing community to help produce the much needed medical equipment components and protective gear for the doctors and nurses in the front line. On Twitter, Carl Bass, former CEO of Autodesk, shows how he is now designing Face shields for as little as $1 a piece. Been working on some cheap homemade ways to get disposable face shields into the…

Found in Robotics News & Content, with a score of 19.41

HP is delivering a polypropylene (PP) material for additive manufacturing. The new HP 3D High Reusability PP, enabled by BASF, is a durable and chemically resistant material that has been qualified for HP’s production-grade 3D printing systems, and is ideal for customers in the automotive, consumer, industrial and medical sectors. HP also unveiled a new partnership with Oechsler, a global design and manufacturing player, to develop applications for both the new PP and HP’s broader materials portfolio, as well as new customer Cobra Golf for its Metal Jet 3D printing technology. Door defroster vent used in the ventilation system of…

Found in Robotics News & Content, with a score of 19.37

6K and 6K Additive, a developer of microwave plasma technology for the production of advanced materials, has been awarded a Phase ll SBIR program from the Defense Logistics Agency (DLA), following the success of its Phase I. The Phase II program supports the development and commercialization of a domestic and commercially scalable supply chain for high-performance metal powders from scrap sources. Using 6K's UniMelt microwave plasma platfrom the program will demonstrate 6K's capability to source, process and reclaim nickel superalloy scrap components, shop scrap, and used powders for conversion into aerospace grade powders. The new powders will be used to…

Found in Robotics News & Content, with a score of 19.22

…of precision metrology, inspection, and assembly products for advanced manufacturing. Wilsonville, Ore.-based DWFritz designs, builds, and supports engineered-to-order, high-speed, non-contact metrology and automation systems. “This is in line with our strategic focus to grow organically and through acquisitions in the advanced manufacturing space, with special focus on industrial software, industrial metrology, and additive manufacturing solutions,” stated Stefan Widing, president and CEO of Sandvik. DWFritz Automation has offices in France and China. The company said it has many Fortune 500 customers and more than 2,000 systems installed worldwide. In 2020, the company had about 560 employees, revenues of approximately SEK 720…

Found in Robotics News & Content, with a score of 19.06

…the pandemic. With its rapid and distributed production capabilities, additive manufacturing technology was literally built for such a moment. Printer manufacturers, technology companies, and engineers are stepping up to help fill the gap in the medical supply chain—and more help is needed. Universities (and some high schools, and individuals working in livings and garages) across the country have converted their engineering departments and 3D print labs into make-shift factories for churning out PPE. On-demand manufacturing and prototyping operations, as well as manufacturers of other types of products, have converted all or part of their capacity to address the shortages. Hobbyists…

Found in Robotics News & Content, with a score of 19.03

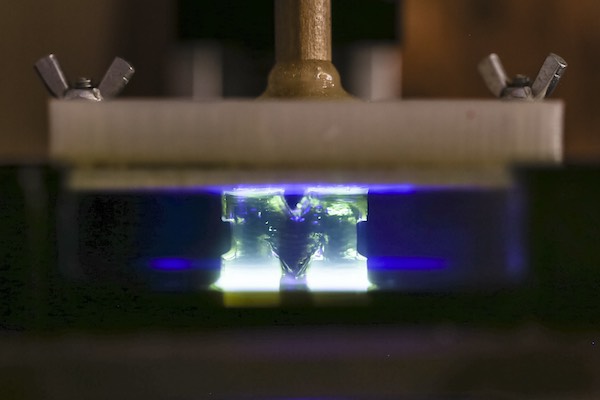

…a paper outlining the new approach. In particular, SLA additive manufacturing, which uses photopolymerizable resin and a light source to cure the cross-sectional layers of geometry making up the part, can be especially slow since performance is limited by the need to initiate time-consuming separation or recoating steps between the layers of the output. Print speeds in most available SLA systems range from only a few millimeters to several centimeters an hour, and the process often yields parts with ridged surfaces, which are not suitable for production-grade products, the paper noted. Rapid, Continuous Additive Manufacturing The University of Michigan’s research…

Found in Robotics News & Content, with a score of 19.01

3D Systems’ Board of Directors named manufacturing CEO veteran Dr. Jeffrey A. Graves as the new president and CEO, effective May 26. Graves brings 17 years of CEO experience and a proven track record for leading, operating and growing technically complex businesses, the company says. He replaces Vyomesh Joshi (VJ), who announced his retirement in February. “I am incredibly excited about the opportunity at 3D Systems. Digital manufacturing will play a key role in the transformation of manufacturing, and 3D Systems is uniquely positioned with its portfolio of additive manufacturing systems, material science, software and domain expertise to help companies…

Found in Robotics News & Content, with a score of 18.86

…(SLA) and selective laser sintering (SLS) 3D printers for manufacturing. The industries it servers span everything from aerospace, architecture, art and automotive to consumer goods, eyewear, healthcare, machinery and service bureaus/contract manufacturers. In Plymouth, the focus is on medical production and sales/marketing for Materialise software for additive manufacturing and medical applications. On this night, the focus was “3D in the D,” accentuated by the “Built in Detroit” theme underpinning the evening’s highlights. Upon entering the 45,000-sq.-ft. building, we were greeted by Materialise leadership and staff, and received a 3D-printed puzzle base to save for the tour, during which we'd collect…

Found in Robotics News & Content, with a score of 18.76

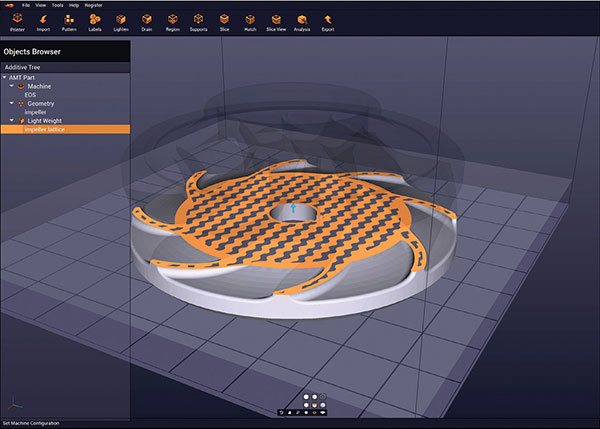

Although additive manufacturing offers clear advantages in many manufacturing applications, current design and simulation resources may be challenged by the complex computational fluid dynamics simulations and shape optimization processes required. Cloud and high-performance computing resources can help companies take better advantage of new design possibilities enabled by 3D printing without requiring a costly investment in new compute resources. 3D print designs that can be simulated and optimized in an HPC environment (on-premise or, increasingly, in the cloud) will be a key enabler of digital manufacturing applications. A number of simulation software vendors, for example, have been working to allow their…

Found in Robotics News & Content, with a score of 18.67

…expand the advancement of industrial 3D printing and digital manufacturing. The expanded alliance with BASF centers around HP’s newly announced polypropylene material for additive manufacturing. The HP 3D High Reusability PP enabled by BASF was developed and qualified for HP’s Jet Fusion 5200 Series 3D printing solution to enable companies to design and produce 3D printed parts faster, more cost-effectively, more sustainably, and at higher volumes, the company says.http://www.hp.com/go/3Dprinting. “The advancement of our long-standing partnership with HP truly demonstrates our shared vision to help transform industries, enable sustainable production, and enable our customers to shape the Additive Manufacturing industrialization,” said…

Found in Robotics News & Content, with a score of 18.53

…makes carbon fiber more accessible to the engineering and manufacturing community with high-performance F170, F270 and F370 3D printers. The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, an alternative to metal parts. The material is said to be stronger and stiffer than standard ABS, without the weight of metal, and can be printed with accuracy, Stratasys notes. QSR Support water-soluble material enables ability to 3D print intricate and complex parts without manual support removal. Stratasys’ internal analysis suggests the additive manufacturing market for polymer jigs and fixtures is expected to grow at a 14.2% annual rate between…