Editors’ Picks

Found in Robotics News & Content, with a score of 12.58

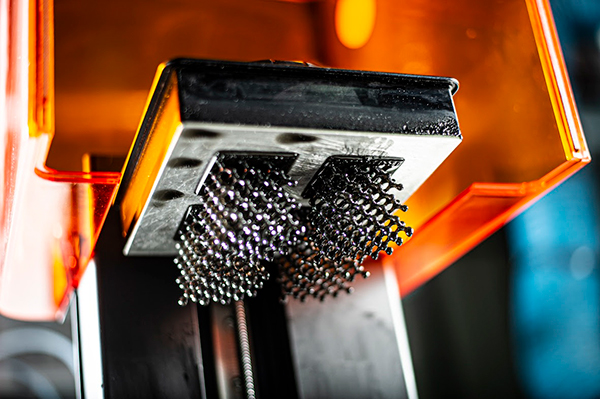

…with eyes and brain. In simple terms, the jetting-based additive manufacturing system employs machine vision and machine learning/artificial intelligence (AI) capabilities to learn the properties of materials, predict behavior, and adjust printing over time. The goal: High precision, multi-material production-grade output. The start-up company, spun out from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) in 2017, is based on research led by Professor Wojciech Matusik and intellectual property licensed from MIT. Inkbit saw reason to create a new platform for 3D printing because while they believed there was substantial opportunity for ink jet AM capabilities, the technology was only…

Found in Robotics News & Content, with a score of 14.82

…latest products to be announced in the company’s IROPRINT additive manufacturing platform, according to Huntsman. IROPRINT F 80112 filament is a shore A78 thermoplastic polyurethane (TPU) and the softest, most flexible material in the IROPRINT range. Made from a polyester-based TPU, IROPRINT F 80112 filament is designed for fused filament fabrication (FFF) and other forms of extrusion-based printing, and is suitable for use in the production of footwear, hoses and gaskets, robotic grippers, seals and other rubber-like applications. IROPRINT R 1801 resin is a radiation cured, one-component polyurethane-based resin that is optimized for easy processing via stereolithography (SLA) digital light…

Found in Robotics News & Content, with a score of 26.22

…the city and its airport, will feature a 30-acre additive manufacturing (AM) “neighborhood” that brings together materials suppliers, 3D printing providers and manufacturers. The 3D printing cluster and the PAIC are launching as the Allegheny County Airport Authority begins work on its Terminal Modernization Program. The 3D printing neighborhood (Neighborhood 91) was officially announced on October 25, although some details were presented at the America Makes Members Meeting & Exchange (MMX) event. “This will be Pittsburgh’s 91st neighborhood,” says David Storer, manager of Real Estate Development at the Allegheny County Airport Authority. “It will condense and connect all the components…

Found in Robotics News & Content, with a score of 14.21

Despite the increased interest in metal additive manufacturing (AM), engineering organizations are struggling to find a definitive formula to make a business case for the technology as a viable method for production. There is no one calculation or cost-benefit analysis that justifies the economics—often, it will come down to a more nebulous equation based on “it depends.” Metal AM, though around for the last couple of decades, has garnered a lot of attention recently as new capabilities and materials innovations advance what the platforms are capable of producing while lower price points put the technology in reach of a wider…

Found in Robotics News & Content, with a score of 23.83

In June 2019, long-time additive manufacturing industry vet Ron Hollis took over as president and CEO of MFG and set about rebuilding the manufacturing marketplace. To DE readers, he may be best known as the founder of custom parts services company Quickparts.com in 1999. He led the firm through a period of rapid growth until 3D Systems acquired it in 2011. He spoke to Digital Engineering about the changes that are happening at MFG, as well as his thoughts on the present state and future of the additive manufacturing market. Digital Engineering: Can you tell us about the impetus behind…

Found in Robotics News & Content, with a score of 29.06

…3D printing is growing rapidly thanks to advancements in additive manufacturing technology, an expansion of available materials and interest from manufacturers in shifting to the production of printed end-use parts in some applications. This is happening despite challenges around cost and quality management. While the market is still in the early phases of adoption in many industries, interest is clearly high. According to a Markets and Markets report, the 3D metal printing market could experience a compound annual growth rate of more than 28%, reaching $2 billion by 2023. That growth is coming from a variety of aerospace, automotive, healthcare…

Found in Robotics News & Content, with a score of 30.28

…a 3D printing ecosystem, aimed at driving innovation in additive manufacturing and encouraging its adoption across industries, the companies report. Together, the two companies will co-develop new 3D printed solutions for medical, automotive and apparel applications. DSM and Twikit are currently working on an end-to-end production workflow for 3D printed orthotics and prosthetics, showcasing additive manufacturing's customizability. Combining DSM’s materials and market reach with Twikit’s experience in software development and application development will facilitate improvements in advanced manufacturing techniques, the companies report. The partnership between the two companies will lead to new customizability and made-to-measure turnkey solutions across various industries.…

Found in Robotics News & Content, with a score of 39.02

…new analysis model to address opportunities associated with metal additive manufacturing production and applications. Using an analysis methodology of metal additive technology adoption metrics and dynamics already tracked by other SmarTech analysis services, this latest report gives insight into the industries and applications driving metal AM, and expectations for what business cases and areas of application will grow. SmarTech expects that metal AM will continue to gradually amass more and more production-oriented business cases, resulting in hundreds of billions of dollars in impact to the global manufacturing market over the next decade. For more details on the report, click here.…

Found in Robotics News & Content, with a score of 33.38

SAE International has released additive manufacturing (AM) polymer specifications for the aerospace industry. AMS7100: Fuse Filament Fabrication Process and AMS7101: Material for Fused Filament Fabrication reportedly represent the first specifications released under the AMS-AM Additive Manufacturing Non-Metallic (AMS-AM-P) committee, according to SAE International. These standards were created after a request from airlines through the International Air Transport Association (IATA)'s EMG to be able to realize additively manufactured plastic cabin parts. “Both additive manufacturing users and producers will benefit from implementing AMS-AM standards,” says Paul Jonas, director of Technology Development & Programs at the National Institute for Aviation Research (NIAR) and…

Found in Robotics News & Content, with a score of 7.37

There’s plenty of interest in deploying additive manufacturing (AM) technologies for production applications, yet a number of factors, including cost, complexity, and a scarcity of industrial-grade materials, has stymied companies’ efforts to make a serious transition to the new model. The tide is starting to turn thanks to a spate of new industrial-grade AM technologies and more recently, a wave of new advanced material choices that are making it easier and more affordable for companies to 3D print production-grade parts. New high-performance materials tuned to withstand harsh environments and that exhibit properties on par with injection molded parts are giving…

Found in Robotics News & Content, with a score of 5.07

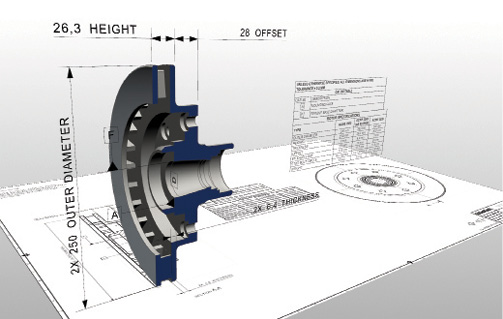

…include parameters such as performance or spatial requirements, materials, manufacturing methods and cost constraints. Through an iterative process, the software explores all possible permutations and quickly generates several design alternatives, learning what works and what doesn’t from each iteration (Fig. 2). Current use cases have shown that generative design can reduce part weight by as much as 30% using traditional manufacturing and 70% using additive manufacturing. This approach also promises to enable innovation beyond that which can be achieved with the human mind, providing solutions to complex problems that would be resource-exhaustive with conventional means. Fig. 2: Generative design taps…

Found in Robotics News & Content, with a score of 24.82

In October, novices to additive manufacturing (AM) have the chance to take a special DfAM (design for additive manufacturing) course to understand how to design parts and assemblies to take advantage of 3D printing. Offered in partnership with America Makes, the event will be organized and led by Terry Wohlers, president of Wohlers Associates, and other instructors. DE is also a media partner of America Makes. The one-day DfAM course will take place in Youngstown, OH, on October 24. Wohlers Associates publishes the annual Wohlers Report that outlines the market trends and leading players in the AM industry. According to…