Editors’ Picks

Found in Robotics News & Content, with a score of 21.79

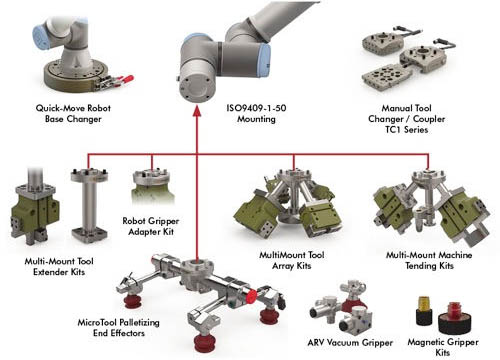

…has launched a new portfolio of end-of-arm tooling, or EOAT, that it said is designed to help customers using collaborative robots and small-payload robots in their operations. The Auburn Hills, Mich.-based company said the tools are designed for cobots handling payloads up to 10 kg (22 lb.). The tools can be used to complete gripping, palletizing, machine tending, tool changing, and tool-extension applications. Destaco, a Dover Corp. company, said it is a leader in the design and manufacture of high-performance automation, workholding, and remote-handling systems. The company serves customers in a variety of end-markets, including the automotive, life sciences, consumer…

Found in Robotics News & Content, with a score of 9.27

…can also integrate with many types of end-of-arm tooling (EOAT), which is important for dexterity in clean room applications. These design qualities improve the robot’s ability to safely and delicately handle fragile materials. Clean room robots can also be designed with an interior vacuum or high-grade seals to prevent particulate shedding. Staubli provides six-axis arms that are rated for clean room applications. Yamaha’s clean room actuators have high-grade seals that serve a dual purpose — the seals prevent dust debris from leaking from the robot and improve suction for a performance boost. How clean room robots can work safely The…

Found in Robotics News & Content, with a score of 12.17

…in the process of developing its own end-of-arm tooling (EOAT). New Balance turns to AMRs and forklifts for materials handling New Balance uses a range of different robots to help move items across the facilities. Truck unloading robots, palletizing robots, box-cutting robots, autonomous mobile robots (AMRs), and autonomous forklifts are among the systems the company has invested in for that part of the operation. “This is more of a mature space,” she said. “We’re looking at things that other companies can provide to help us make this whole operation run smoother.” Looking ahead Since New Balance is building out its…

Found in Robotics News & Content, with a score of 26.22

…cups and pumps, as well as full end-of-arm tooling (EOAT) and custom systems. Piab reported sales of about 1.9 billion SEK ($180 million U.S.), more than 1,000 employees, and four divisions. It serves customers in more than 100 countries from a network of subsidiaries and distributors. Joulin brings wood expertise Piab said it has partners and customers in the food and beverage, automotive, packaging, logistics and warehousing, e-commerce, electronics, chemicals, pharmaceutical, and manufacturing industries. The global market for materials handling robots could expand from $8.3 billion in 2021 to $25.9 billion by 2027 at a compound annual growth rate (CAGR)…

Found in Robotics News & Content, with a score of 17.46

…that.” OnRobot was founded in 2018 and develops a range of products designed for the robotic manufacturing industry, including EOATs, a turnkey palletizing solution, and software suites.

Found in Robotics News & Content, with a score of 10.35

…controller. With the ability to have multiple end-of-arm tools (EOAT) attached to it, the robot has the flexibility to handle a variety of print and labeling tasks “for flat containers, round containers, and everything in between,” the company said. “Epson has made robotic automation easy for organizations looking for operational simplicity and flexibility as requirements can change quickly,” said Scott Marsic, group product manager at Epson Robots, in a statement. “Epson All-in-One 6-Axis robots are versatile, supporting a variety of applications in addition to label application, ranging from pick and place to dispensing and more. “With robots that are easy…

Found in Robotics News & Content, with a score of 17.09

…the following components: Six-axis robotic arm Custom end-of-arm tool (EOAT) AI powered machine vision Integration with the WES AI enables a comprehensive, intelligent system Unlike traditional industrial robotic applications, these bin-picking robots aren’t trained to do a singular task with set inputs and outputs. Thanks to artificial intelligence, the robots can problem solve for an infinite amount of new and complex situations, like new SKU integration, with no training required. When an inventory bin is presented to the machine vision system, a photo is taken to map out the objects’ orientations. Within a split second, AI vision identifies the “most…

Found in Robotics News & Content, with a score of 13.66

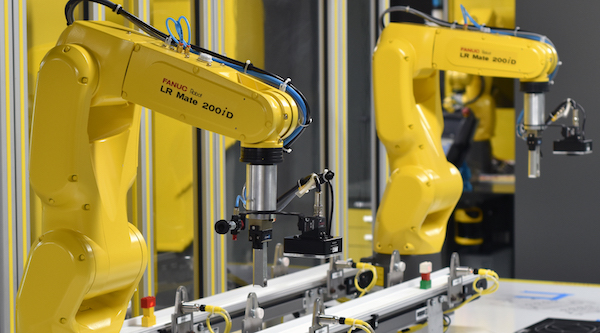

…availability, and productivity.” Robot arms placed with end-of-arm tools (EOAT) are also on display taking advantage of SICK’s object detection technologies. “On display at PACK EXPO, you’ll see how robot arms are enhancing picking and how they can create a safe and productive work environment,” the company said. More on PACK EXPO SICK is located at booth N5929 on the trade show floor. It will also be hosting several demonstrations and one educational session focused on intelligent sensors, robotic end-effectors, and vision solutions. PACK EXPO in Chicago is put on by the Association for Packaging and Processing Technologies and features…

Found in Robotics News & Content, with a score of 8.98

…inspection BeBop Sensors is in talks with end-of-arm tooling (EOAT) providers, and warehouse automation companies are interested in being able to perceive loose items or sense items when optical systems are occluded, said McMillen. “We have a short list of 80 customers and are speaking with them in order of their interest,” he said. “We have multiple pilots under way with some big warehousing and automotive companies.” “We've also anticipated apparel, because we have the ability to detect texture, not just force,” McMillen added. “We pick up variations at a pretty high sample rate and can classify them. Automating things…

Found in Robotics News & Content, with a score of 12.12

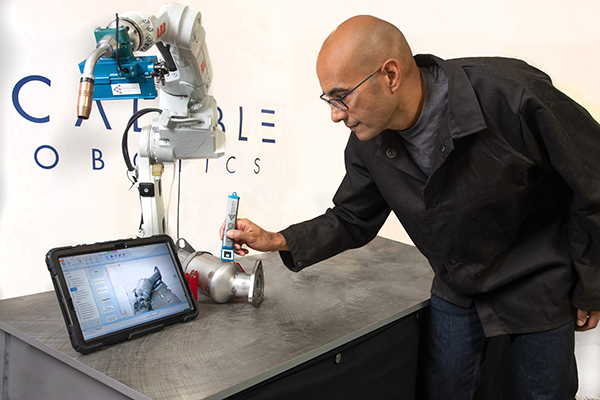

…a protective box attached to the robot end-of-arm tooling (EOAT). It uses a touchscreen interface to guide the welder through the scanning, teaching, validation, and tuning steps. The welder teaches the robot the positions of the welds by clicking a handheld stylus to indicate the desired approach, path, and departure points of the weld. Scalable's platform automatically generates a weld path that is validated within RobotStudio, ABB’s simulation and programming software. The operator makes any final modifications before the robot auto-tunes the program and sends it to the robot controller so the weld can be performed, explained Scalable Robotics. ABB…

Found in Robotics News & Content, with a score of 15.12

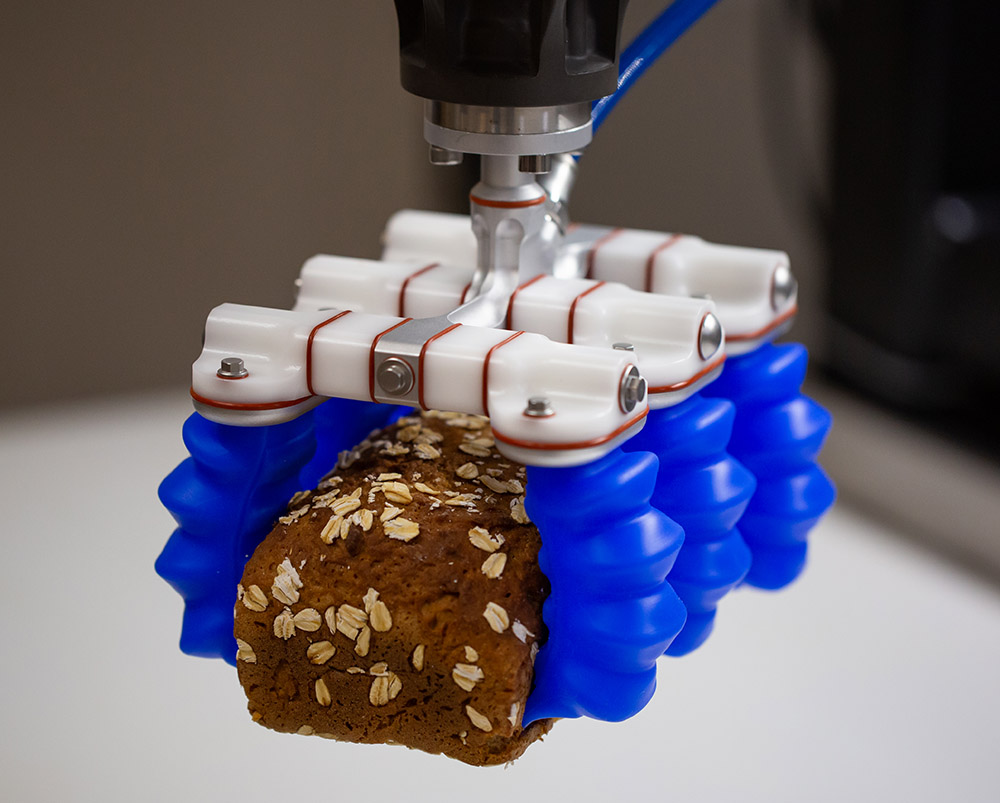

…lb.). Thanks to a telescopic linear air-operated actuator, the EOAT can grasp parts the size of a golf ball or small blister pack, depending on the suction cup arrangement. It can hold a wide range of shapes and surfaces, even loose or nonrigid objects, said the company. The MAXXgrip's actuation is designed so it can be executed in parallel with the approach/depart motion segments used in pick-and place cycles. Its response time is 0.15 to 0.4 sec., but as this motion typically takes around the same time for the robot arm to move, it minimizes dwell time in successive picking…

Found in Robotics News & Content, with a score of 33.42

…lower maintenance costs, and cut down on food waste. EOAT market to grow The end-of-arm tooling (EOAT) market is expected to continue to grow in the coming years as various industries continue to invest in automation. Research and Markets reported that the EOAT industry is expected grow by $829 million between 2021 to 2025 at a compound annual growth rate (CAGR) of 4.75%. The company’s exhibit will be at Booth 5003 in the North Hall of the Las Vegas Convention Center. The conference runs from Sept. 18 to 21. Staubli Robotics will also be displaying the mGripAI system at its…