Editors’ Picks

Found in Robotics News & Content, with a score of 13.63

…but also eliminates the need for specialized end-of-arm tooling (EOAT) and force sensing during sanding tasks.” An EsVata staff member operates Flexiv’s Rizon 4 adaptive robot arm with an OnRobot sander attached to the universal mounting flange. Source: Flexiv Robotics By automating sanding, EsVata’s employees are now freed from monotonous, labor-intensive sanding tasks, which enables them to engage in more valuable roles within the company. Flexiv said this reallocation of human resources underscores EsVata’s commitment to enhancing employee satisfaction, and highlights its belief in enhancing the impact of human labor through collaborative robotics rather than replacing it. Customized interface, universal…

Found in Robotics News & Content, with a score of 13.04

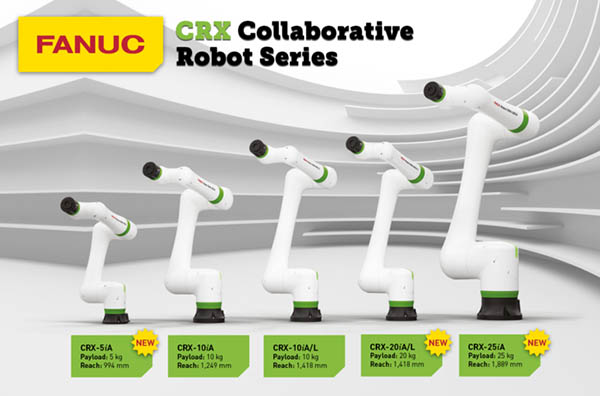

…models are designed to be easy to connect to third-party devices, including FANUC-approved CRX device suppliers for end-of-arm tooling (EOAT), grippers, accessories, and plugins. Industrial automation suppliers interested in having their products become part of the CRX device program should contact FANUC. Demos and shipping to come FANUC plans to demonstrate all five CRX models at IREX (International Robot Exhibition) Virtual from March 1 to 18, and at IREX from March 9 to 12, at the Tokyo Big Sight in booth E4-04. The company said it will begin shipping production units of the new CRX-20iA/L in April. The CRX-25iA and…

Found in Robotics News & Content, with a score of 12.94

…to be integrated between robot arms and end-of-arm tooling (EOAT), maintaining the integrity of internal cable routing. Bota said many robotic arm manufacturers are moving towards internal routing to eliminate cable tangles and motion restrictions. Bota offers a uniform interface across all models to facilitate integration. Its design minimizes external connections and component count, significantly enhancing system reliability. “Our objective is to equip robots with the sense of touch, making them not only safer and more user-friendly, but also more collaborative,” said Klajd Lika, Bota CEO and co-founder. “PixONE is an advanced, OEM-ready sensing solution that enables robot developers and…

Found in Robotics News & Content, with a score of 12.89

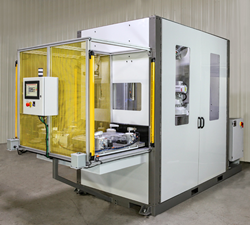

…ABB IRB 2600 robot and a multiple-purpose end-of-arm tool (EOAT) mounted to the robot. The deburring and pre-machining system automatically removes excess material from die-cast aluminum parts. The parts arrive from the casting deck, are inspected, and loaded into one of the two fixtured shuttles in the MiniMAC, the robot and tool remove the unwanted materials from each part and the finished part is returned to the operator complete. Other features of the MiniMAC Grind System, include choices in robot model, part presentation techniques, and tooling used to remove excess materials. Each MiniMAC cell and the larger MAC and MegaMAC…

Found in Robotics News & Content, with a score of 12.84

…in active/passive compliant technology, brush sanding, and end-of-arm tooling [EOAT].” “It's hard to ignore the strides being made by collaborative systems,” he said. “It's not trying to displace industrial automation, but we think cobots are opening the marketplace to a whole group of customers who never would have considered automation and can now benefit.” Kane Robotics to exhibit with partners Application partners Applied Automation, ATI industrial Automation, and FerRobotics sought out Kane Robotics to exhibit GRIT cobots in each of their booths at Automate 2023 because GRIT operationalizes their products and services in realistic scenarios, said the company. In the…

Found in Robotics News & Content, with a score of 12.17

…in the process of developing its own end-of-arm tooling (EOAT). New Balance turns to AMRs and forklifts for materials handling New Balance uses a range of different robots to help move items across the facilities. Truck unloading robots, palletizing robots, box-cutting robots, autonomous mobile robots (AMRs), and autonomous forklifts are among the systems the company has invested in for that part of the operation. “This is more of a mature space,” she said. “We’re looking at things that other companies can provide to help us make this whole operation run smoother.” Looking ahead Since New Balance is building out its…

Found in Robotics News & Content, with a score of 12.12

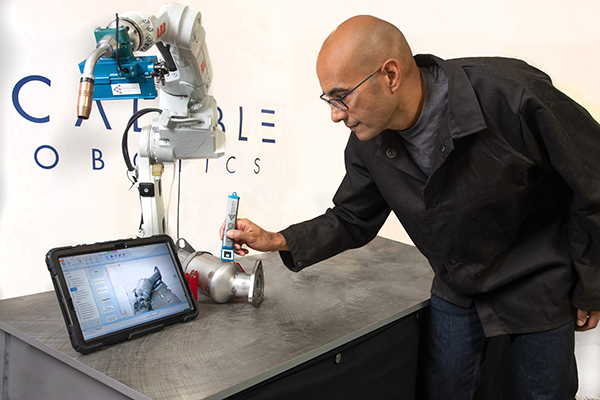

…a protective box attached to the robot end-of-arm tooling (EOAT). It uses a touchscreen interface to guide the welder through the scanning, teaching, validation, and tuning steps. The welder teaches the robot the positions of the welds by clicking a handheld stylus to indicate the desired approach, path, and departure points of the weld. Scalable's platform automatically generates a weld path that is validated within RobotStudio, ABB’s simulation and programming software. The operator makes any final modifications before the robot auto-tunes the program and sends it to the robot controller so the weld can be performed, explained Scalable Robotics. ABB…

Found in Robotics News & Content, with a score of 10.86

…tending OnRobot said a stronger end-effector, or end-of-arm tooling (EOAT) platform for industrial robots deployed in collaborative applications enables improved workpiece adaptability. The company’s new grippers offer an all-round plug and produce experience, including fingers with multiple configurations, flange adapters, cabling, and software that removes complexity of robot programming, said OnRobot. “As cobots grow more powerful, OnRobot customers are scaling up their collaborative applications,” says Enrico Iversen, OnRobot CEO. “Building on the success of our existing, industry-proven gripper range, the new 3FG25 and 2FG14 grippers deliver unrivaled gripping and payload power while also providing customizability for heavy-duty applications, including harsh…

Found in Robotics News & Content, with a score of 10.67

…component in the finished product. Specially designed end-of-arm tooling (EOAT) allows for highly stable and exact positioning of labels. 5. Applications for automation in post-processing Post-processing robots can inspect, test, and hot-stamp plastic molded parts. For example, an eight-axis robotic trimming cell provides superior repeatability compared with a human performing the same task. Robots can also improve precision, accuracy, and cycle times, lessening waste and minimizing errors. Simply put, robots can make a big difference in cost-effectiveness and production waste while freeing workers from repetitive manual work. Robotics has tremendous potential to change the future of business operations. The robotics…

Found in Robotics News & Content, with a score of 10.35

…controller. With the ability to have multiple end-of-arm tools (EOAT) attached to it, the robot has the flexibility to handle a variety of print and labeling tasks “for flat containers, round containers, and everything in between,” the company said. “Epson has made robotic automation easy for organizations looking for operational simplicity and flexibility as requirements can change quickly,” said Scott Marsic, group product manager at Epson Robots, in a statement. “Epson All-in-One 6-Axis robots are versatile, supporting a variety of applications in addition to label application, ranging from pick and place to dispensing and more. “With robots that are easy…

Found in Robotics News & Content, with a score of 10.10

…30 kg (66 lb.), which allowing for end-of-arm tooling (EOAT) weight, means it can easily palletize cartons or cases in the 22-25 kg range, using wizard-like software to design pallet patterns and in effect configure, rather than program a solution, said Chris Caldwell, product manager with Yaskawa Motoman. While there are robotics applications with high variability that call for advanced vision software from partners, said Caldwell, using a cobot to palletize and leveraging simple software for setup can fit the needs of many small-to-medium enterprises looking to step into automated palletizing with robotics. “We believe robotics should only be as…

Found in Robotics News & Content, with a score of 9.90

…also developed sensors, motion control systems, and end-of-arm tooling (EOAT), he said. Customization and personalization with robots Coffin gave an example of how kitting works with robots and people. “I get a box of tea every month, and it comes with these different pieces,” he said. “There's the key box that comes with it, and there's a pamphlet, and then there's always something like a little spoon.” “It's representative of a lot of the customers that we've been talking to lately,” Coffin said. “Robotics offers opportunities to not have people doing the repetitive task of placing these items in boxes…