Editors’ Picks

Found in Robotics News & Content, with a score of 37.63

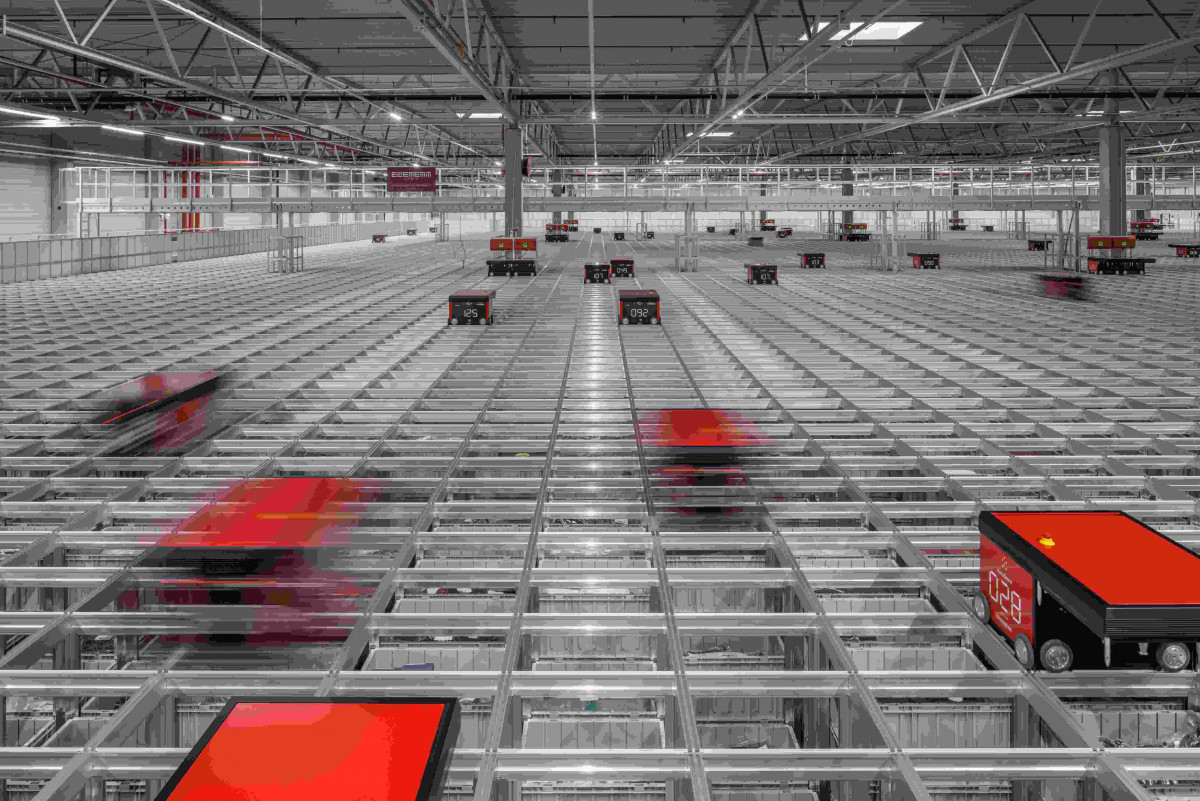

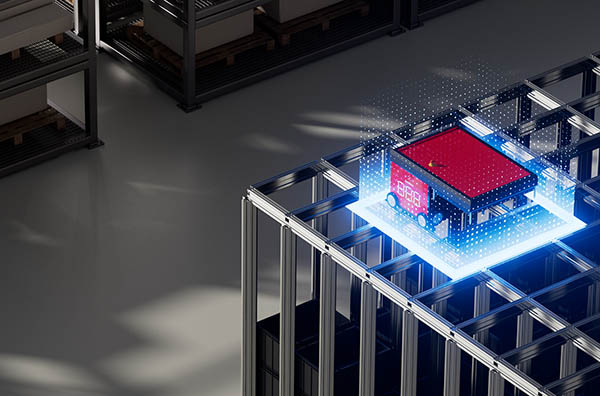

AutoStore AS has announced that its fulfillment automation technology, with more than 1,150 systems in operation worldwide, is now available as a pay-per-pick service. The new offering will enable a lower entry price point to help retailers meet the growing need for more efficient warehouse operations and faster customer delivery, the Nedre Vats, Norway-based company said. AutoStore, founded in 1996, said it is a technology company that develops automated storage reterival systems to help businesses achieve efficiency gains within the storage and retrieval of goods. The company offers both hardware and software capabilities, and the AutoStore technology is interoperable with…

Found in Robotics News & Content, with a score of 5.08

…multiple deployments, and service-level agreements.” DHL has relationships with AutoStore, Boston Dynamics, Locus Robotics, and Vecna Robotics, among others. “The balance between existing, fixed infrastructure and flexible automation and ROI [return on investment] is based on the customer,” said Gary Allen, vice president of supply chain excellence at Ryder Supply Chain. “AMRs [autonomous mobile robots] need one and a half years, while an ASRS may take one to two years, depending on volume.” MMH's Bob Trebilcock moderated a session with Drew Bailey, vice president of design engineering at Geodis; Zac Boehm, vice president of innovative systems at Hy-Tek Intralogistics; and…

Found in Robotics News & Content, with a score of 13.34

…partnerships with Element Logic, Vanderlande, and a couple of AutoStore partners. We've seen growth and the extension of piece picking with AutoStore's ASRS. A new customer was Apotea, a Swedish e-commerce pioneer. It started in 1997 with high-value, low unit-volume prescriptions and took the pharmacy online. Today, it has $500 million in revenue and an 80% CAGR [compound annual growth rate] over 10 years. The European company built a highly automated warehouse, but it didn't want 1 million sq. ft. Sure, Walmart acquired Alert Innovation in October, but ASRS is like an erector set—it can be put up pretty quickly.…

Found in Robotics News & Content, with a score of 24.06

AutoStore AS today announced a new report for which it surveyed more than 300 C-level business leaders in warehouse management and fulfillment. Respondents cited the top three challenges facing their organizations as rising energy costs (32%), increasing labor costs (27%), and supply chain and shipping constraints (26%). Click on image to enlarge. Source: AutoStore “There is a need to operate more efficiently, which is perhaps why nearly nine in 10 organizations either have, or are planning to install, automation technology in their warehouse in 2023,” stated Ellen Brune, head of global strategic accounts at Nedre Vats, Norway-based AutoStore. “The intention…

Found in Robotics News & Content, with a score of 3.90

…lifts and pallet carriers optimize the growing trays like AutoStore bots move totes to optimize access to inventory, although perhaps not as often. What’s more, the software and technology operating the farm was designed in house and custom built for Bowery Farming, including the ASRS and conveyor system. To make that happen, the company invested heavily in talent: Frankert, for instance, previously worked at SoftBank Robotics, where he focused on technologies for micro-fulfillment centers in the 7,500 to 10,000 square foot range. Pallets of plants are moved by conveyor into the main grow area. Source: Jeff Fusco/Getty Images for Peerless…

Found in Robotics News & Content, with a score of 25.50

…help of systems integrator Element Logic to install an AutoStore automated storage retrieval system, or ASRS, that now covers 6,000 square meters at the facility. The system is made up of 160 robots, which are being used to sort orders for clothing store customers across Europe, including Peek & Cloppenburg Düsseldorf, one of its largest. The Bonn, Germany-based company said the facility warehouses more than 3.5 million fashion items for customers in places such as Austria, Poland, and the Netherlands, and is used to process new merchandise as well as returns. AutoStore system allows for more efficient tracking “The AutoStore…

Found in Robotics News & Content, with a score of 4.38

…Solutions Group. SoftBank's $2.8 billion acquisition of 40% of AutoStore is the stuff of legends. Another axis of consolidation to consider is companies that possessed technology that couldn’t stand on its own but is cool. There are some really interesting components, like perception AI to predict traffic flows from camera data. That's abstract enough that very few end customers that know what to do with it. SVT is partnering with Ox on augmented reality picking. Integrating AMRs [autonomous mobile robots] with voice picking—there's so much upside from these types of human augmentation. We pride ourselves that we’re the “Switzerland of…

Found in Robotics News & Content, with a score of 33.33

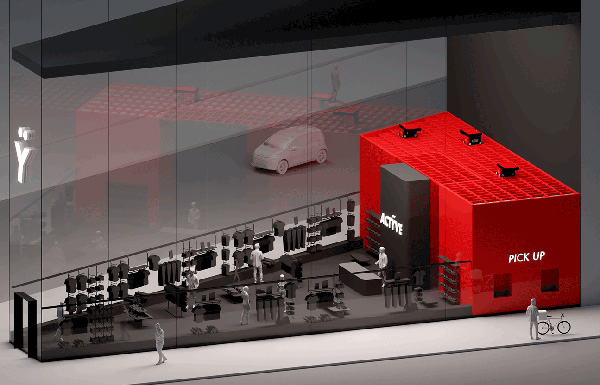

AutoStore yesterday announced the North American launch of Pio, which stands for “Product In/Out.” The Nedre Vats, Norway-based company said Pio is a plug-and-play version of its cube storage technology tailored for small and midsized businesses, or SMBs. Based on a pay-per-pick service model, Pio allows SMBs, such as retailers of apparel, sporting goods, crafts, and cosmetics, to deploy automation with a relatively low investment. The goal is to enable more businesses to gain access to its technology, said AutoStore. “We established Pio to make our technology available to smaller businesses,” said Mats Hovland Vikse, CEO of AutoStore. “Only 15%…

Found in Robotics News & Content, with a score of 35.49

…Corp. announced last week that it is working with AutoStore to automate its 873,000-sq.-ft. warehouse in Kentucky where it holds music, movies, video games, electronics, arcades, and collectibles. AutoStore makes automated storage retrieval systems (ASRS), which are designed to help facilities better take advantage of vertical space for picking and moving products. Alliance Entertainment’s ASRS configuration includes AutoStore’s latest-generation B1 robots combined with over 52,000 storage bins. Each bin is configurable and can hold up to eight unique SKUs with a maximum weight of 66 lb. It covers 22,200 sq. ft. of the company’s 873,000-sq.-ft. warehouse. Those systems enable a…

Found in Robotics News & Content, with a score of 15.57

…the U.S. to implement a robotic goods-to-person system from AutoStore. The original site was a 600,000-square-foot distribution center north of Chicago in Libertyville, Ill. That first deployment, featured in the June 2015 issue of Modern Materials Handling (a sibling publication to Robotics 24/7), sported 43 bots in a relatively small area plus four goods-to-person workstations. The robots managed 27,570 totes across 37,750 storage locations with throughput of up to 12,500 lines per day. It was a bold move but even then, Medline was embracing high levels of automation technologies across its network, including numerous sortation technologies. Fast forward, and one…

Found in Robotics News & Content, with a score of 32.10

AutoStore AS yesterday announced its new Unify Analytics cloud-based service and data platform. The technology enables businesses using AutoStore's automated storage and retrieval system, or ASRS, to gain access to data-led insights and identify the cause of operational issues, said the company. Unify Analytics is available in two versions, a Web application where businesses can view real-time statistics and analytics, and an API that enables seamless integration with external third-party applications. “Businesses can reap multiple benefits by combining automated storage and retrieval and data-led insights,” stated Andreas Munch, product manager at AutoStore. “This data analysis tool will allow businesses to…

Found in Robotics News & Content, with a score of 17.77

…sequencing—buffers before and after the picking process from an AutoStore automated storage and retrieval system (ASRS). “By using AMRs, we can help our customers to improve internal processes, increase efficiency, and offer them faster and more reliable order processing,” stated Hans-Jörg Braumüller, group design and consulting director at Element Logic. Since 1985, Element Logic said it has been optimizing warehouse performance with robots, ASRS, fulfillment systems, software, and services. The Kløfta, Norway-based company serves the electronics, third-party logistics (3PL), pharmaceutical, apparel, and other industries. Element Logic also claimed that it is the world's first and largest AutoStore integrator. Earlier this…