Editors’ Picks

Found in Robotics News & Content, with a score of 4.21

…helps users effectively convey their project requirements, guiding ChatGPT to create the desired applications,” said the company. Badger Technologies' inventory robots use Orbbec's 3D cameras and SLAM. Source: Badger Technologies Orbbec offers support to accelerate development The AI-Aided SDK Programming Guide also comes with 24/7 technical support and customized sample codes, said Orbbec. The new programming guide is intended to simplify and accelerate the software development process, it added. Orbbec said its guide can increase progamming efficiency and ease of use for its 3D camera. Users can request more information about the AI-Aided SDK Programming Guide at [email protected].

Found in Robotics News & Content, with a score of 4.21

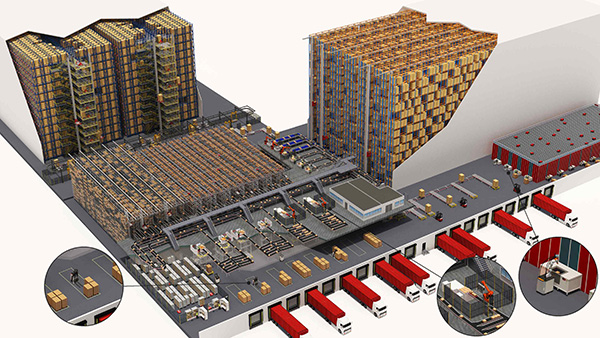

…height of 12 m (39 ft.) to enable high-density inventory storage. The goods-to-person system automates manual physically intensive tasks and can reduce order-fulfillment times, Exotec claimed. In addition, the company offers integration services, from pre-system consultation to continuous post-implementation maintenance. More than 30 brands, including Carrefour, Decathlon, Gap, and Uniqlo, use Exotec's technology to improve their operations and profitably navigate rapid shifts in business models and customer expectations, said the company. Exotec expands in Japan Yokohama, Japan-based Alps Logistics provides transportation, storage, import/export, and product distribution services worldwide. It mainly serves electronic components companies that require specialized material handling techniques,…

Found in Robotics News & Content, with a score of 4.20

…transformation, they were key partners in our distribution automation journey.” Lane Automotive deployed Exotec’s Skypod system to manage its inventory while improving the speed and accuracy of its pick, pack, and ship operations. A fleet of 62 ARMs, 5 picking stations, and 59,600 storage bins were deployed at its distribution center. “Our project with Lane Automotive showcases the immense potential of warehouse robotics in revolutionizing even the most challenging logistics operations swiftly and efficiently,” said Stanislas Normand, managing director of Exotec North America. Lane Automotive expects to realize a sixfold increase in throughput as a result of integrating Exotec’s Skypod…

Found in Robotics News & Content, with a score of 4.18

…and automated guided carts (AGCs). The third task is inventory management, which even includes the use of aerial drones. Let’s take a closer a look at the eight types of robots that are commonly used in warehouses today. Which types of robots are best to deploy always depends on the unique circumstances of a warehouse’s operations, facility, and overall goals. This is why we always recommend seeking advice from a specialized supplier or integrator. About the author Michelle Schlechtriem is the content manager at Meili Robots. She writes about marketing, technology, and sustainability. Meili Robots provides a universal fleet management…

Found in Robotics News & Content, with a score of 4.18

…use of storage space for Kwik Trip’s sizeable fast-moving inventory with bagged products stored in around 80,000 plastic trays stacked up to 20 trays high across the warehouse floor. “Cimcorp’s automation is central to enabling this efficient product movement and is therefore pivotal to our bakery business. Cimcorp worked closely with us to develop an ideal solution that would make optimal use of our warehouse space and meet our present and future business needs,” says Eric Fonstad, facility director at Kwik Trip. Order picking is managed by Cimcorp’s MultiPick system that features six overhead gantry robots inside three cells that…

Found in Robotics News & Content, with a score of 4.18

…central system to continuously recalculate order fulfillment priorities and inventory movement patterns. The entire mechanism is based on real-time factors such as order fulfillment commitments, factual fulfillment speeds, available resources, and time remaining in dispatch windows. “Material handling efficiency inside the distribution center is a key issue faced by the supply chain teams, especially at retail companies,” said Subhodip Bandyopadhyay, General Manager - Emerging Digital Retail Technology, UST Global, “GreyOrange offers a robust yet flexible solution, where we will see a rise in our positive customer experience leading to a 3X gain in productivity. This is applicable even for complex…

Found in Robotics News & Content, with a score of 4.16

…of warehouse management systems (WMS) to manage transactions and inventory at the distribution center level and then hand order requirements down to the automation layer is not as simple as it used to be. With the complexities of e-commerce fulfillment, the need to orchestrate and optimize operations is driving the need for advanced execution software in the middle of the stack and for more optimization tools. In short, the DC tech stack has changed. It’s no longer just WMS on top, warehouse control system (WCS) software in the middle, and automated materials handling systems at the floor level. The stack…

Found in Robotics News & Content, with a score of 4.15

…space for optimal speed and can even pick up inventory. Rack-to-person technology, developed by Geek+, optimizes storage by 30% compared to facilities without the tech. A blueprint for the future of e-commerce: UPS Velocity is now one of our largest and most technologically advanced facilities. With the e-commerce market predicted to grow at 11.9% over the next five years, UPS Velocity is built to deliver on that demand now and into the future. Customer experience a top priority: UPS Velocity ensures orders can be fulfilled quickly and efficiently to meet customers’ expectations. With the help of skilled team members, UPS…

Found in Robotics News & Content, with a score of 4.14

…the only platform enabling multi-purpose robotic solutions, including Tennant’s Inventory Scan, it’s now even more critical for machines to run longer so they can be utilized more frequently while employees focus on other value-added assignments,” he added. Brain Corp said its BrainOS cloud-connected platform enables robotics developers to build scalable, self-driving robots to clean floors, move inventory, and sense environmental data—turning manual operations into automated workflows. It offers its systems through a robotics-as-a-service (RaaS) model. The San Diego, Calif.-based company said Fortune 500 brands across multiple verticals use the growing portfolio of BrainOS-powered robots and its privacy, safety, and efficiency…

Found in Robotics News & Content, with a score of 4.08

…digital manufacturing technology makes it possible to shift from inventory-focused production to a more customer-centric approach, the companies report. Materialise has helped advance the fast transformation of the hearing aid industry. The company is now using its expertise to transform the eyewear industry by creating a digital manufacturing platform. “3D printing holds the potential to transform industries by making it possible to create unique designs, manufacture in small batches and offer levels of personalization never seen before. With three decades of 3D printing experience, Materialise is ideally positioned to drive these industry transformations,” says Alireza Parandian, Global head of business…

Found in Robotics News & Content, with a score of 4.06

…was recently highlighted in the media after marshaling its inventory of 3D printers to produce reusable respirator masks using the open-source design made available by the inventors of the Montana Mask. The response for masks has been overwhelming, which led USD to seek additional assistance from companies and individuals with 3D printers to help increase production to meet the large demand. The maker community answered the call, and this inspired Matt O'Brien, CEO of Unique Software Development, to conceptualize and launch MakerCause to create a movement to help fight COVID-19. “After receiving an outpouring of offers from makers to help…

Found in Robotics News & Content, with a score of 4.06

…orders to fill for the day, the location of inventory and density of the picks, the system will assign three to six cobots to an associate. Totes are conveyed to an induction area, and then items are conveyed to packing to complete the orders for shipping. Once a cobot receives an assignment from the robotic control system, it travels to the pick location. An associate in that area then walks over to complete the assignment and picks the required number of units to the tote. Associates wear a Bluetooth-enabled identification badge that communicates with the cobot. That allows the unit…