Editors’ Picks

Found in Robotics News & Content, with a score of 21.31

…will extend its capabilities into mass production of metal additive parts. “With the Digital Metal acquisition, Markforged is advancing our vision for distributed manufacturing by enabling the reliable, high-volume production of precise metal parts at the point of need,” stated Shai Terem, president and CEO of Markforged. “Infusing Digital Metal’s solution into The Digital Forge platform allows us to address new applications in the medical, automotive, luxury goods, and other industries.” The Digital Forge is Markforged's integrated metal and carbon-fiber additive manufacturing (AM) platform. The company said it “brings the power and speed of agile software development to industrial manufacturing,…

Found in Robotics News & Content, with a score of 21.29

…announced the release of new Simulation features for its additive manufacturing software. Simulation is available as a free trial until April 2023 and as a paid subscription thereafter, said the company. As both 3D printing and simulation software move from prototype to production, the complementary technologies promise to save manufacturers time and money previously spent on design/print/break testing cycles, according to Markforged. The Watertown, Mass.-based company said Simulation enables virtual testing of materials and designs for demanding applications. “This conversion of hardware, software, and materials comes down to confidence,” said Doug Kenik, principal product manager at Markforged. “Without Simulation, additive…

Found in Robotics News & Content, with a score of 21.28

…how technologies fit together with each other in Smart Manufacturing. The report identifies eight transformative technologies: ● Additive manufacturing ● Artificial intelligence (AI) and machine learning (ML) ● Augmented reality (AR) ● Blockchain ● Digital twins ● Edge intelligence ● Industrial Internet of Things (IIoT) platforms ● Robotics According to ABI, The manufacturing sector has already seen increased adoption of IIoT platforms and edge intelligence. Over the next ten years, manufacturers will start to piece together the other new technologies that will eventually lead to more dynamic factories less dependent on fixed assembly lines and immobile assets. Each step in…

Found in Robotics News & Content, with a score of 21.09

…agreement with Atlantic Coastal Acquisition Corp. The Pflugerville, Texas-based additive manufacturing company said it expects use the $346 million in cash from the deal to fund organic growth initiatives. Founded in 2013, Essentium said it develops industrial 3D printing solutions across systems, materials, software, and services “to enable a new distributed and sustainable manufacturing footprint.” The company claimed that its ecosystem can quickly create high-quality parts that match the strength of injection molding in full-scale production at a very low total cost of ownership (TCO). “Essentium is transforming the future landscape of supply chains by delivering truly distributed, sustainable manufacturing…

Found in Robotics News & Content, with a score of 20.98

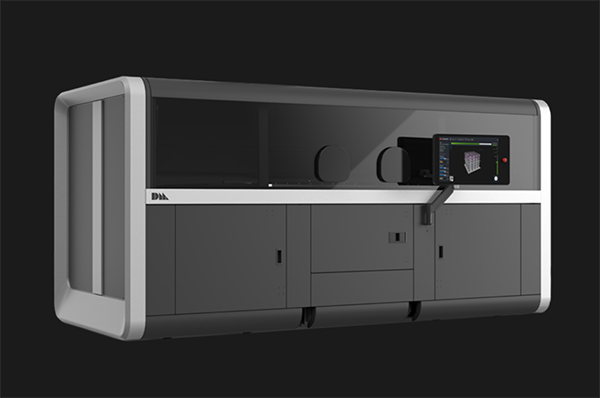

…to achieve the fastest build speeds in the metal additive manufacturing market, claimed the Burlington, Mass.-based company. “The qualification of 316L stainless steel with leading mechanical properties on the Production System platform is part of our aggressive roadmap to support an array of materials for binder jetting,” stated Jonah Myerberg, co-founder and chief technology officer of Desktop Metal. “[It is] a testament to the advantages of SPJ technology, which enables mass production throughput without sacrificing part performance and repeatability.” “With 316L on the Production System P-50, businesses will now be able to leverage additive manufacturing to produce complex, end-use parts…

Found in Robotics News & Content, with a score of 20.94

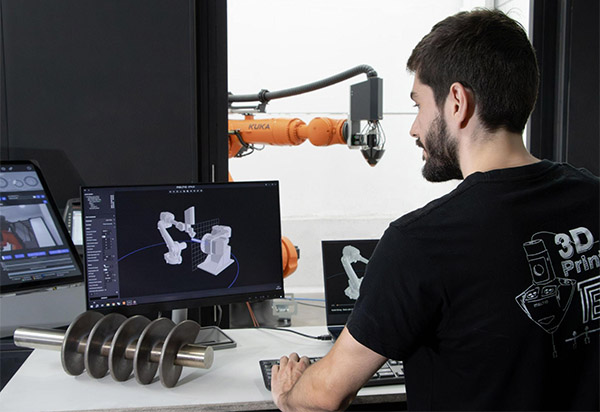

…described itself as a leader in wire-laser metal deposition additive manufacturing, today announced the Meltio Space software. The company said Meltio Space is a toolpath generator designed to accelerate adoption of its technology and help users benefit from robotic 3D printing without requiring expertise in robotics or programming. “Meltio Space makes it possible to design very reliable parts as quickly as possible and with a wider range of possibilities for our industrial customers,” stated Alejandro Nieto, Meltio Engine product manager. “This is thanks to a very user-friendly interface of the Meltio Engine Robot Integration.” “The learning curve of our Engine…

Found in Robotics News & Content, with a score of 20.87

…of industry analysis and market forecasting data to the additive manufacturing (AM) industry, has released its fourth annual market study on the polymer additive manufacturing segment. In the report the firm quantifies the global economic impact of polymer 3D printing including, for the first time, a deep analysis of revenues associated with 3D printed parts. Driven in the long term by opportunities in direct AM production, SmarTech now expects polymer 3D printing to generate $11.7 billion in revenues in 2020, grow to $24 billion in 2024 and as much as $55 billion yearly by the end of this decade. For…

Found in Robotics News & Content, with a score of 20.80

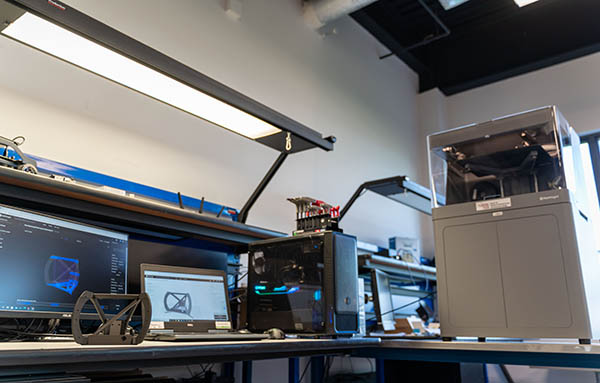

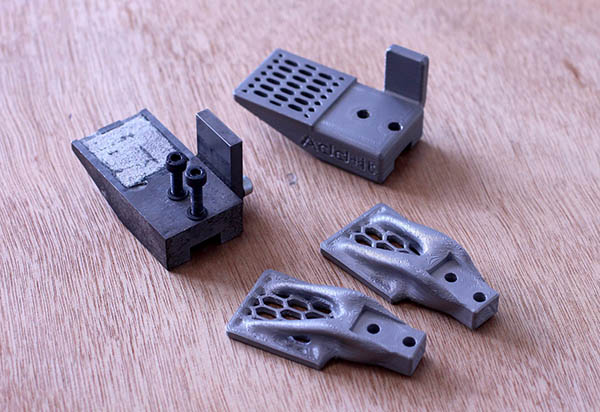

A key part of digital manufacturing is the use of software and hardware that can be readily modified for flexible production. Preziosa Francesco SRL, a sheet metal manufacturer, wanted to create custom robotic grippers for each job. Conventional machining would take too long, so the Bergamo, Italy-based company turned to 3D printing with the help of Additive Italia SRL, Desktop Metal Inc., and nTopology Inc. Preziosa Francesco realized that CNC machines would require long lead times to create new grippers for its existing robotic cell and automated press bending machine. The company worked with design engineers from Additive Italia (Add-it)…

Found in Robotics News & Content, with a score of 20.79

…is a prime example of how our unique multi-material additive manufacturing technology can rapidly accelerate development cycles and time-to-market,” says Amit Dror, CEO of Nano Dimension. “We have been working with HENDSOLT since we initiated our beta program two years ago and are excited to see how they are continuing to leverage our multi-material additive manufacturing technology into new application areas to further increase efficiencies across its development process.” “With its novel multi-material capability, the DragonFly Pro is bringing rapid prototyping and agile workflow possibilities to electrical engineers and companies from many industries,” says Sven Dengel, CEO of Phytec New…

Found in Robotics News & Content, with a score of 20.79

Additive manufacturing (AM) software and services vendor Materialise says two data points tell the story of 3D printing for manufacturing. The first is 80%, the percentage of manufacturers using 3D printing in some fashion, primarily prototyping. The second is 50%, the amount of waste typically generated by laser sintering, the most popular process for prototyping. Both percentages come from Materialize polling existing clients and customers. Materialise also says their clients would increase the use of additive manufacturing processes if they could reduce risk, reduce cost, and reduce time to return on investment (ROI). “If you assume 3D printing is by…

Found in Robotics News & Content, with a score of 20.63

…defense suppliers, contractors, and manufacturers gather for the AeroDef Manufacturing Conference (April 29-May 1), produced by the Society for Manufacturing Engineers (SME). A growing area of interest for the attendees is the deployment of digital twins—not just for objects, such as jet engines and helicopters, but also for entire factories, plants, and processes. Exhibitors such as JR Automation and Siemens highlight the technologies available for digital twins in their booths. Also at the show are Creaform, which develops 3D scanning devices; and 3D Systems, an additive manufacturing (AM) system developer. Attendees and featured panelists discuss the concerns for cyberphysical security,…

Found in Robotics News & Content, with a score of 20.58

…and opens up options for new applications in polymer-based additive manufacturing, such as for filter units and fluid channels, plugs and other electronic components as well as consumer goods such as eyeglasses. EOS is presenting this technological concept for the first time at formnext 2019. “The new technology will combine the best of two worlds—the detailed resolution of stereo lithography (SLA) with the durability and quality of selective laser sintering (SLS),” Dr. Tim Rüttermann, senior vice president Polymer Division, says. “In future, depending on application requirements, customers will therefore be able to choose between the existing EOS P 500 version…