Editors’ Picks

Found in Robotics News & Content, with a score of 13.91

…The group has used a 3D printer to create plastic molds that can function as a microenvironment for hair follicle growth. The process could be a way to facilitate the growth of human hair follicles in a laboratory to slow or prevent hair loss. According to team leader Angela Christiano, the Richard & Mildred Rhodebeck Professor of Dermatology at Columbia university Vagelos College of Physicians and Surgeons, growing human hair from cell cultures has historically been difficult. While rat and mice hairs have been grown in a dish using cell cultures, but human hair cultures have never produced reliable results.…

Found in Robotics News & Content, with a score of 8.09

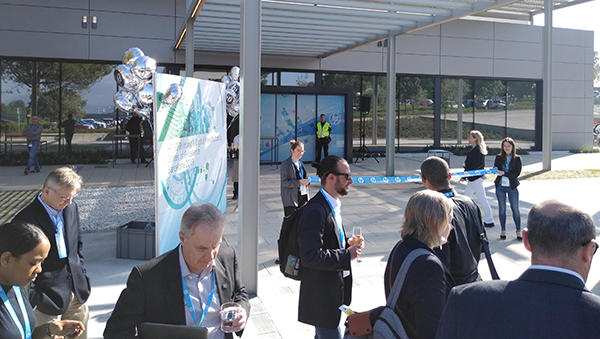

…HP’s Ramon Pastor, general manager and global head of Plastics Business, HP 3D Printing and Digital Manufacturing Groups, told a group of industry press and analysts invited to the June 2019 grand opening of the new HP 3D Printing and Digital Manufacturing Center of Excellence in Barcelona, Spain. Delayed by the discovery of Roman-era ruins on the building site, the new center is an extension of HP’s existing Barcelona campus, and is now headquarters for both HP’s 2D wide-format printing and 3D digital manufacturing endeavors. 100 3D printers are in use for its own part production as well as doing…

Found in Robotics News & Content, with a score of 12.26

…decrease in orders from automotive component suppliers (-16 percent), plastics and rubber (-16 percent), electronics (-17 percent), and metals (-17 percent). Orders from automotive original equipment manufacturers (OEMs) were up 41 percent, however, as were orders from the food and consumer goods industries (+32 percent). Another bright spot was the solid increase in orders over the fourth quarter of 2018, with units up nearly 16 percent and revenue up nearly 9 percent. In the first quarter of 2019, 7,577 robots, valued at $452 million, were shipped, down 29 percent in units and nearly 11 percent in dollars from the same…

Found in Robotics News & Content, with a score of 13.12

…groups, customers, and partners with fleets of the latest plastics and metals 3D production systems for rapid and agile product development. Image courtesy of HP. The new Center of Excellence unites hundreds of 3D printing and digital manufacturing experts in systems engineering, data intelligence, software, materials science, design and applications. Specifically designed for active collaboration across HP engineering and R&D groups, customers and partners, the new facility integrates flexible and interactive layouts, co-development environments, and fleets of the latest HP plastics and metals 3D production systems to drive more rapid and agile product development and end-to-end solutions for customers. Leaders…

Found in Robotics News & Content, with a score of 6.02

…(eg. barcodes) that are covered by dust, wrapped in plastic, damaged during transit, visible only at angles, or even missing. Other factors to be considered include continuous autonomous flights, ambient conditions, rate of inventory turnover, ease of integration with WMS, frequency of cycle counts, size and layout of each warehouse, time to set up and charge the drones, aisle widths, length of shutdowns, and many more. FlytBase is pleased to share their learnings from customer engagements to help drive broader adoption of drones by warehouses, driven by intelligent software, commodity hardware, and seamless integration. With an approach that combines multi-sensor…

Found in Robotics News & Content, with a score of 7.74

…design verification testing, motor enclosures, and low pressure molding/tooling with transparency for flow visualization. “The newest additions to our plastic 3D printing portfolio demonstrate our commitment to driving the adoption of digital manufacturing,” said Vyomesh Joshi, president and CEO, 3D Systems. “With the industry’s first, truly scalable plastic production platform and our robust selection of materials, 3D Systems enables customers to rethink manufacturing and realize improved agility, reduced complexity, and lower overall total cost of operation.” Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 4.17

…top manufacturing industries represented included food, beverage, and tobacco; industrial machinery; textiles and apparel; paper/printing; computers and electronics; and plastics and rubber (among others). On the non-manufacturing side, respondents work for business/consulting services, retail, wholesale, and third-party logistics providers (3PLs).

Found in Robotics News & Content, with a score of 5.99

…has assembled a new Digital Manufacturing Network to provide plastic parts at scale using HP printing solutions. Initial members are Forecast 3D, GKN Powder Metallurgy, GoProto, Jabil, Materialise, Parmatech and ZiggZagg NV. HP says these initial network members “possess high levels of advanced additive manufacturing expertise, robust quality management and end-to-end manufacturing processes, and a proven capability for volume job production.” There is an innovation alliance with Siemens based on the Siemens Digital Enterprise software portfolio; a materials production alliance with BASF; and a software partnership with Materialise’s Build Processor and Magics 3D Print Suite. Updates to Autodesk Netfabb and…

Found in Robotics News & Content, with a score of 10.00

…production partners, is designed to help produce and deliver plastic and metal parts at scale, by using HP 3D printing soutions. Currently, the network includes partners in the U.S., Asia and Europe. To date, the partners include Forecast 3D, GKN Powder Metallurgy, GoProto, Jabil, Materialise, Parmatech, and ZiggZagg NV. According to the company, HP Digital Manufacturing Network partners have been evaluated and qualified based on their end-to-end 3D printing capabilities for production at scale, as well as their manufacturing and quality processes. The HP-endorsed digital manufacturers are intended to provide local-market coverage to deliver quality, functional plastic and metal parts.

Found in Robotics News & Content, with a score of 8.78

…create glass filaments that were similar in size to plastic filaments typically used with the printer. They then programmed the printer to create two complex shapes. “Our approach is very well suited for soft chalcogenide glass, but alternative approaches are also being explored to print other types of glass,” said Ledemi. “This could allow fabrication of components made of multiple materials. Glass could also be combined with polymers with specialized electro-conductive or optical properties to produce multi-functional 3D printed devices.” The process could also be used for making glass fiber preforms with complex geometries or using multiple materials. “3D printed…

Found in Robotics News & Content, with a score of 8.40

…for the consolidation and densification of metal, ceramic and plastic parts, producing a maximum theoretical density, ductility and fatigue resistance in high-performance materials. “We have evaluated the requirements of 250 international industrial customers for five years, and HIP turned out as an answer to many quality issues,” says Carl Fruth, CEO, FIT AG. “I even think that all additive serial manufacturing will experience a big boost when integrating HPHT as a post-processing service.” Jan Söderström, CEO, Quintus Technologies, welcomes the cooperation with FIT as a groundbreaking step. “We expect that the industrialization of AM in general will be revolutionized once…

Found in Robotics News & Content, with a score of 11.48

…focused on KyronMax, a group of reinforced polymers with strength-to-weight ratio produced by Mitsubishi Chemical Advanced Materials. “KyronMax engineering plastics are among the most competitive materials in the Mitsubishi Chemical portfolio for metal replacement in structural applications,” says Gerbec. “With Freeform Injection Molding, we can achieve outstanding material properties on an additive platform while using our current feedstocks. We are currently testing KyronMAX’s high-performance property retention when used with FIM technology, and the first results are very promising.” More Info AddiFab Sources: Press materials received from the company and additional information gleaned from the company’s website.