Editors’ Picks

Found in Robotics News & Content, with a score of 5.91

…Germany, 3D Systems is showcasing its Figure 4 Standalone plastic 3D printer as a new technology to be integrated in Nokia’s “factory in a box.” The integration of additive manufacturing alongside augmented reality/virtual reality (AR/VR) and robotics, all powered by Nokia private 4G / 5G connectivity, results in a semi-automated production workflow. “After the positive feedback we received for our factory in a box concept last year, it was important to reach a new level with version 2.0,” says Grant Marshall, VP supply network & engineering, Nokia. “We did so in terms of connectivity, because factory in a box 2.0…

Found in Robotics News & Content, with a score of 5.87

…are optimized for high-throughput manufacturing of functional, complex 3D plastic and rubber parts. Adaptive3D's flagship resin is Elastic ToughRubber 90, a durable, printable photopolymer elastomer. The company said it serves high-throughput manufacturing, while maintaining low cost of production and superior material performance. Adaptive3D has received strategic capital from leading materials companies including Covestro, Arkema Group, West Pharmaceuticals, Applied Ventures, and Royal DSM. It noted that Desktop Metal's scale and channel network provide “a massive opportunity” for it to expand. “We are thrilled to partner with Desktop Metal to enable additive manufacturing through our differentiated materials,” said Dr. Walter Voit, founder…

Found in Robotics News & Content, with a score of 5.77

…surface textures, and materials, both rigid packaging and loose plastic Induct with throughput of 1,600 – 2,000 picks per hour (PPH) Fit within the confines of most induction workstations with a footprint of 2.7 by 1.4 m (8 ft., 10 in. by 4 ft., 6 in.). “AI and reinforcement learning are in Kindred’s DNA and embedded in all our products, said Anne Marie Neatham, chief operating officer at Kindred. “Those capabilities enabled us to quickly solve the engineering challenge of automating induction – a more challenging process than picking and sorting due to the unstructured and unpredictable dynamics of handling…

Found in Robotics News & Content, with a score of 5.77

…load and unload rolling carts, handling both boxes and plastic tote bins. Fly-by barcode Scanning—With faster barcode reading, PDP 3.0 does not slow much in loading and unloading cases onto pallets, meaning higher throughput and faster integration into warehouse workflows. Sortation to pallets—PDP 3.0’s ability to sort products directly onto pallets can add a new level of efficiency to logistics operations. Since launching the Dexterity Palletizing and Depalletizing product in January, Dexterity said its customers have received new feature releases that increase its flexibility and utilization rate in warehouse operations. Customers are already addressing staffing shortages with the system, it…

Found in Robotics News & Content, with a score of 5.64

…the tremendous potential to manufacture parts—and vehicles—in ways previously not considered possible. Marcel Spiegler is director, Customer Innovation Center, Plastics, 3D Systems.

Found in Robotics News & Content, with a score of 5.64

…divisions, including BOWE SYSTEC for efficient systems for inserting, plastic card mailing, and mail sorting. BOWE Intralogistics supplies technologies for e-commerce, multichannel retail, parcel distribution services, and manufacturing. BOWE IQ offers software for machine control, warehouse management, process optimization, tracking, and the integrated management of complex, networked automation scenarios. Since 2010, BOWE has been wholly owned by the Lübeck, Germany-based Possehl Group. With around 1,000 employees, some 20 subsidiaries, and over 50 general representatives, BOWE GROUP guarantees fast and local advice, sales, and service support for customers around the world. It led an $8.2 million investment round in MOV.AI in…

Found in Robotics News & Content, with a score of 5.58

…Robotics. Pagès Group supplies complete automation solutions to professional plastic converters worldwide across a range of sectors, including food and beverage, cosmetic, and medical. Lenkering Montage und Zerspanungstechnik GmbH (LMZ) is based in Steinfeld-Mühlen in northern Germany. LMZ specializes in machine construction and machining technology. Its service portfolio includes process development, project planning, and construction of assembly and test systems, as well as linked production lines. Andrew Donald Design Engineering in Victoria, Australia, said it specializes in the design and building of turnkey automation systems. ADDE added that it is a “full-service” solution provider with experience in implementing automation for…

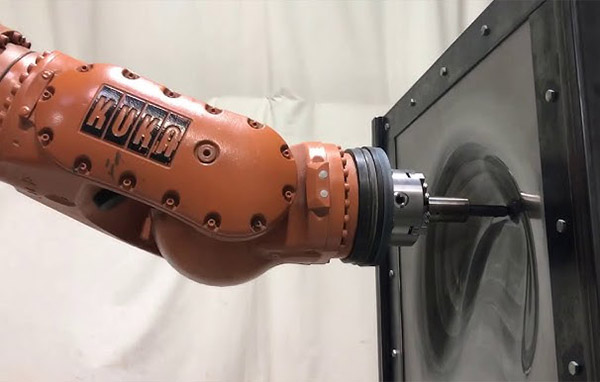

Found in Robotics News & Content, with a score of 5.57

…with a focus on e-mobility, batteries, electronics, metal and plastic, consumer goods, e-commerce, retail, and healthcare. It plans to begin delivering the portable system later this year. Interested parties can contact Machina Labs for more information about price, availability, or training or to request a demonstation. Mehr is speaking at FABTECH. On Sept. 11, he will discuss “Robotic Sheet Shaping: A Thesis on the Future of Manufacturing” at 2:00 p.m. CT in Room S501BC. On Sept. 13, Mehr is participating in a panel entitled “Advancing Robotics in the Fabrication Metal Industry” at 12:30 pm CT in the FABTECH Theater. Editor's…

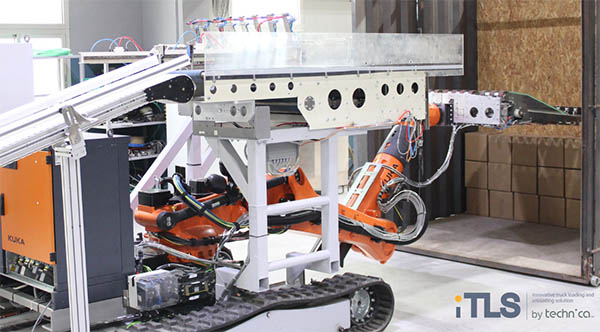

Found in Robotics News & Content, with a score of 5.49

…served by Technica include food and beverage, chemicals, glass, plastic, dairy, pharmaceutical, home and personal care, paint, education, and logistics. The company said its customers include Procter & Gamble, Coca Cola, Heineken, Pepsi, Henkel, Unilever, Nestle, al Marai, and Danone. Other vendors working on robotic palletizing and truck loading and unloading include Boston Dynamics, Dextrous Robotics, and Honeywell Intelligrated. GreyMatter and iTLS promise to increase efficiency iTLS—Powered by GreyMatter can enable 99% palletization efficiency and accuracy when forming rainbow pallets, said the partners. It can also improve ergonomics to eliminate worker fatigue, reduce dock turnaround times by up to 150%,…

Found in Robotics News & Content, with a score of 5.48

…of factors, including gravity, shrinkage, density variations, elastic bending, plastic deformation, friction drag and more. The thermodynamic and mechanical transformations that occur during sintering take place under intense heat, making them difficult to observe without either halting the sintering process mid-cycle or installing windows in the furnace to observe distortions from images taken at high temperature. While such methods are potentially tolerable in R&D environments, they create significant delays and costs in time to market for production applications. Live Sinter can be calibrated to a variety of alloys. It predicts the shrinkage and distortion that parts undergo during sintering, and…

Found in Robotics News & Content, with a score of 5.47

…to fit into the lowest number of bags, reducing plastic use. After being packed, orders are loaded into a temperature-controlled Kroger Delivery van, which can store up to 20 orders. It uses machine learning to optimize delivery routes, considering factors like road conditions and optimal fuel efficiency. The Monroe CFC measures 375,000 sq. ft., includes seven “modules,” and carries thousands of popular grocery products. Kroger said its configuration includes Ocado technology engineered for the flexible Kroger Delivery network, which will also include smaller facilities. The CFC can fulfill thousands of orders per day and support pickup orders. Last week, Ocado…

Found in Robotics News & Content, with a score of 5.42

…also enables us to use certain materials, such as plastics or fabrics, to make our system more flexible, lightweight, and cost-effective. It's only a few thousand dollars, compared with tens or hundreds of thousands.” “These materials also enable us to rapidly prototype and innovate, unlike traditional prototyping and 3D printing, which are time-consuming and expensive,” he added. “This enables us to tailor the system to human anatomy and more easily scale up.” “The knee actuator transmits torque for movement,” he explained. “One area of customization is optimizing fit for comfort. We can take a user's measurements for the thigh and…